item | specification | manufacturer |

Servo motor | ECMA-C20807RS | Taiwan |

server Driver | ASD-B2-0721-B | Taiwan |

PLC main module | CP1L-M30DR-A | Omron |

PLC temperature module | CP1W-TSOO2 | Omron |

PLC touch screen | 6AV6/648-0BC11-3AX0 | Siemens |

Encoder | ZSP3806-003G-1500BZ3-5-24F | United States Rip Ann Waco |

Main motor | RC series helical gear motor | Geer |

frequency | VFD015M21A | Taiwan |

Stainless steel plate | 304 316 | Korea,japan |

Switching power supply | NES-100-24 | Taiwan mingwei |

emergency button | XB2-BS542 | Schneider |

1、Blister packing machine 160R can pack things with aluminum-plastic or aluminum-aluminum packing material and these two functions are very useful and people can freely choose. This equipment is surprisingly low in running costing and remarkably perfect in performance.

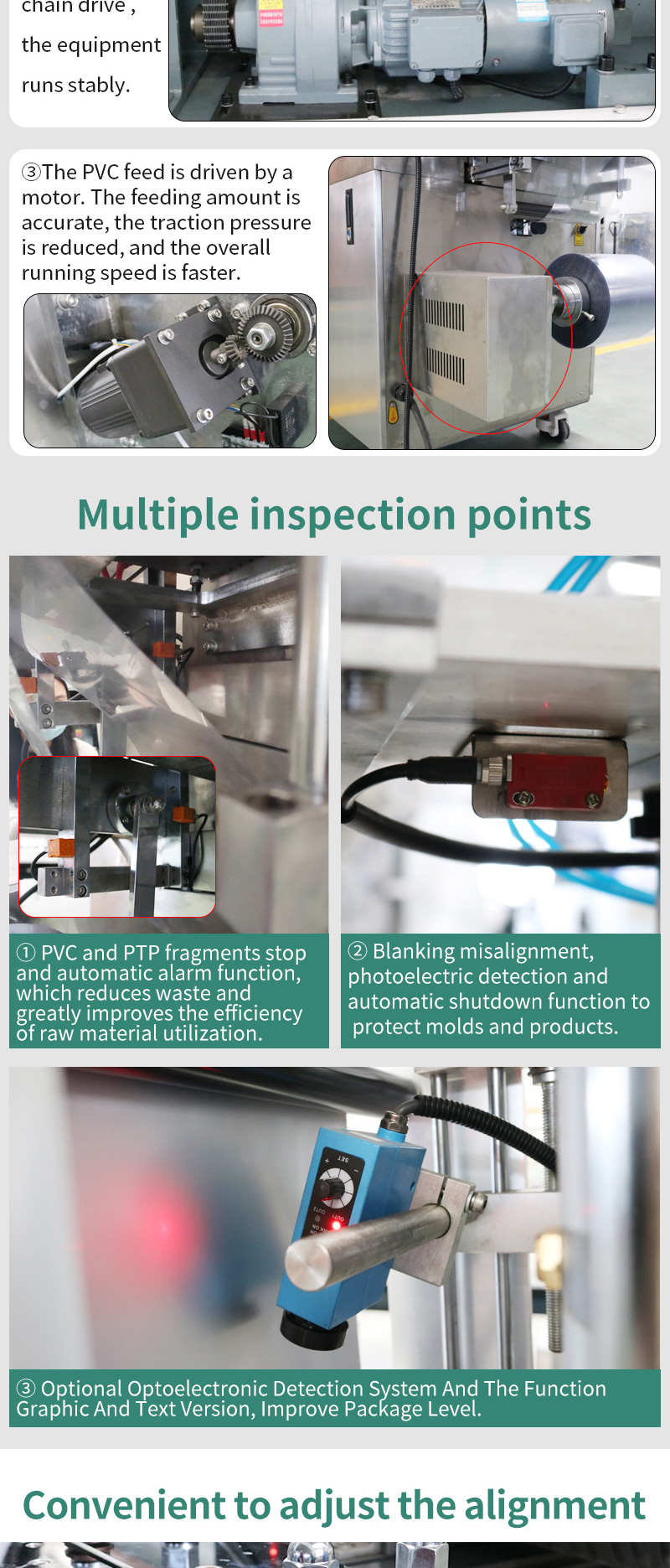

2、 This pill capsule tablet blister packing machine will not retreat any packaging material if it suddenly stops and the running velocity is remarkably fast, it doesn’t have any mistake in its traction precision. All because it has adopted a latest kind of servo motor roller pressing shaft traction.

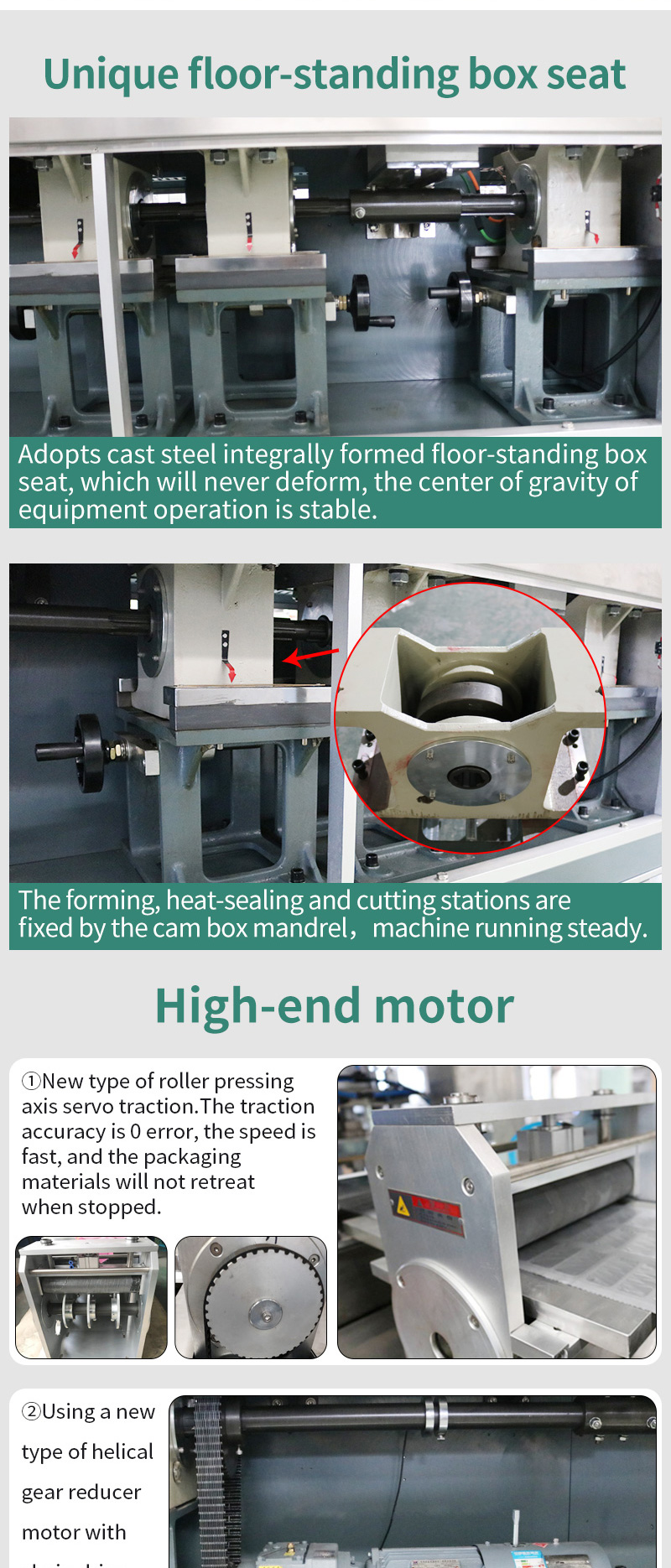

3、From forming, heat-sealing and so on all these parts of capsule blister packing machine will never have deformation because it utilizes design of cast steel uniformly formed floor-standing box seat. And this equipment is remarkably steady in the gravity center and all adjustments on all stations are truly light and excellently accurate.

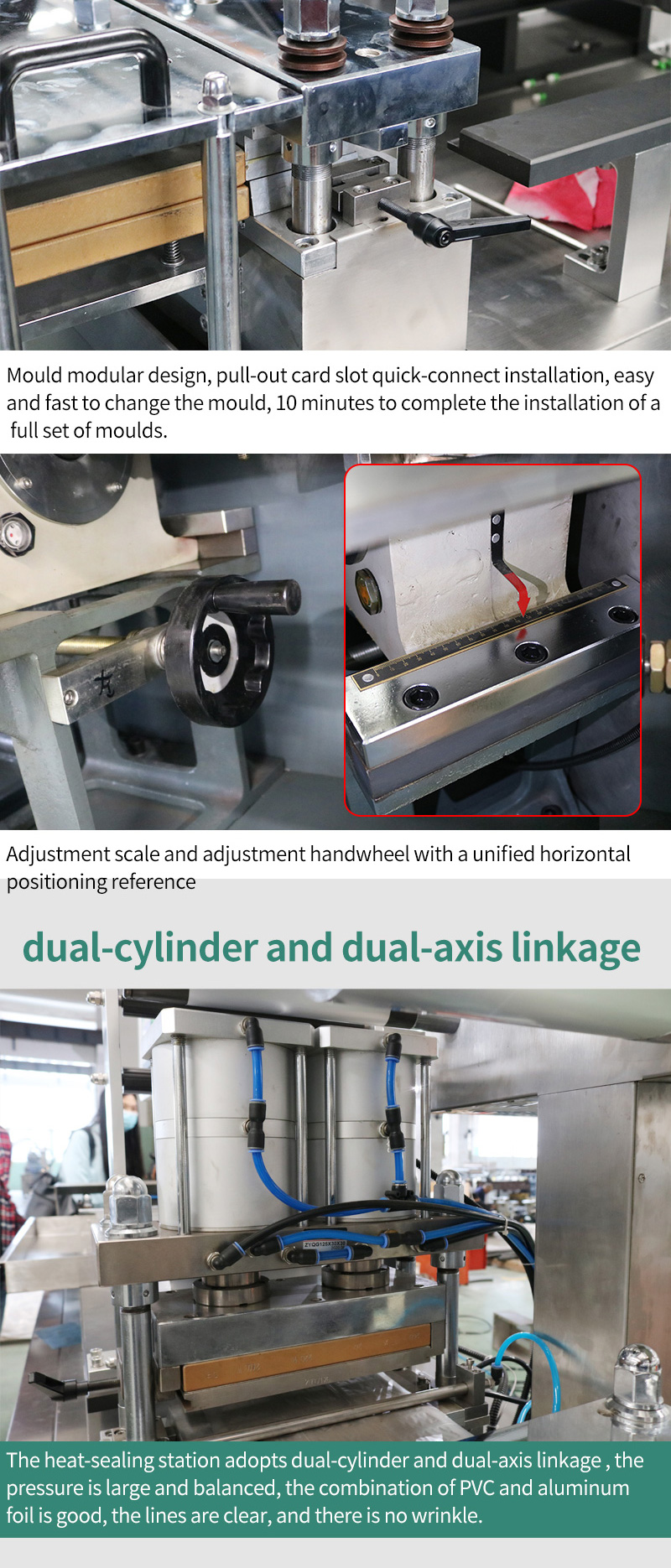

4、 This flat plate blister packing machine is convenient and easy in both cleaning and maintenance when the whole packing is accomplished because its large platform design is very scientific and reasonable.

5、Pill blister packing machine is economic in its automatic PVC and PTP fragments stop and alarm setting which can dramatically reduce any waste and the raw material can be efficiently improved.

6、 All molds can be replaced without any difficulty and the whole set of molds can be installed rapidly in a very short time which can be just 10 minutes.