High Speed Automatic Bottle Capping Packing Counting Production Machine Line

Model | RQ-XG-200D |

Production Capacity(bottles/min) | 80-120 bottles/min (related to the size and shape of the bottle) |

Applicable bottle diameter | φ20~φ80mm |

Specification of bottle | Various round or square bottles |

Applicable bottle height | 30~200mm |

Specification of cap | φ15~φ60mm |

Power Supply | AC220V 50Hz |

Total Power | 2.0kw |

Air consumption | 145L/min |

Outline Dim. | 2500*950*2200mm |

Air Compressor | 0.3-0.6Mpa |

Weight | 850kg |

This high-speed capping machine designed by Guangdong Rich Packing is based on the urgent needs of more and more customers. It is suitable for kinds of PVC PS PE plastic bottles, as well as those glass bottles with different sizes and shapes.

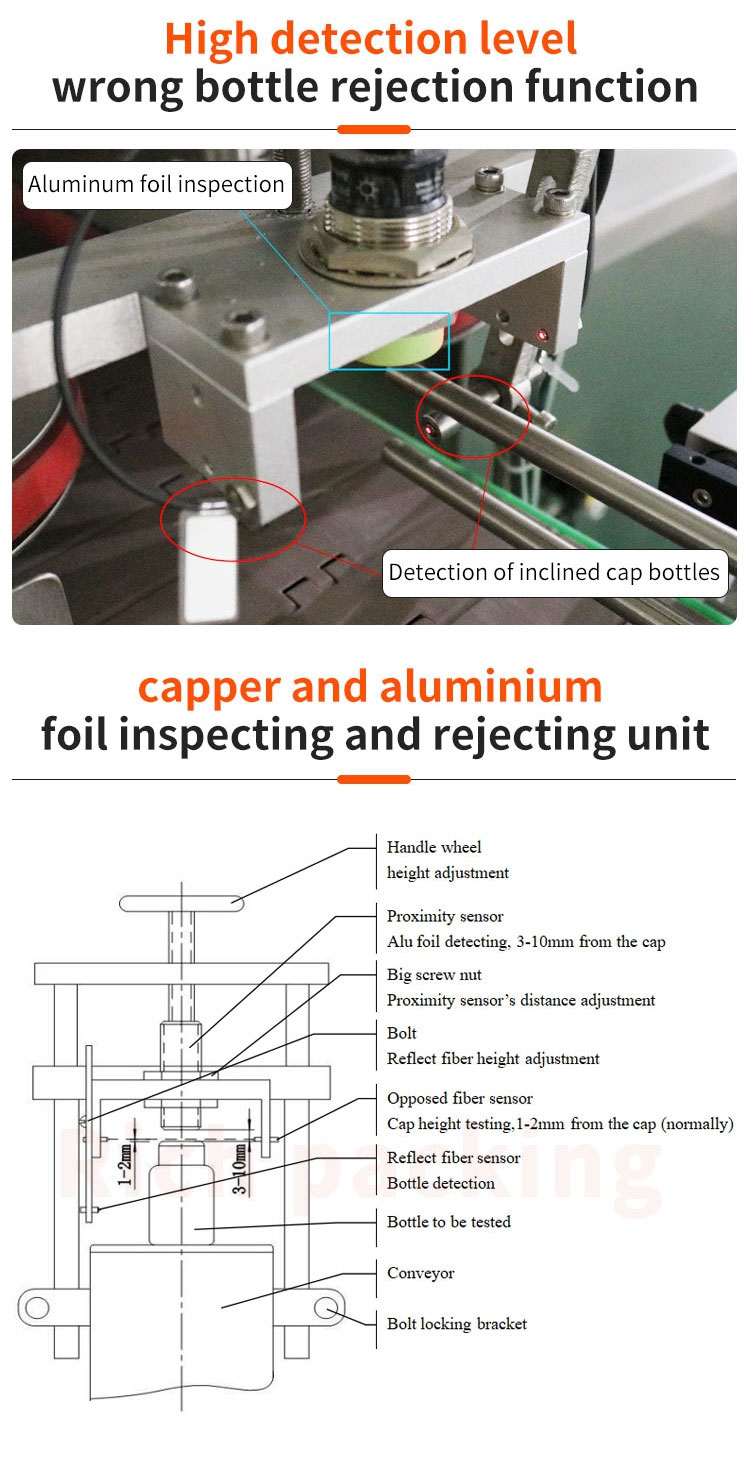

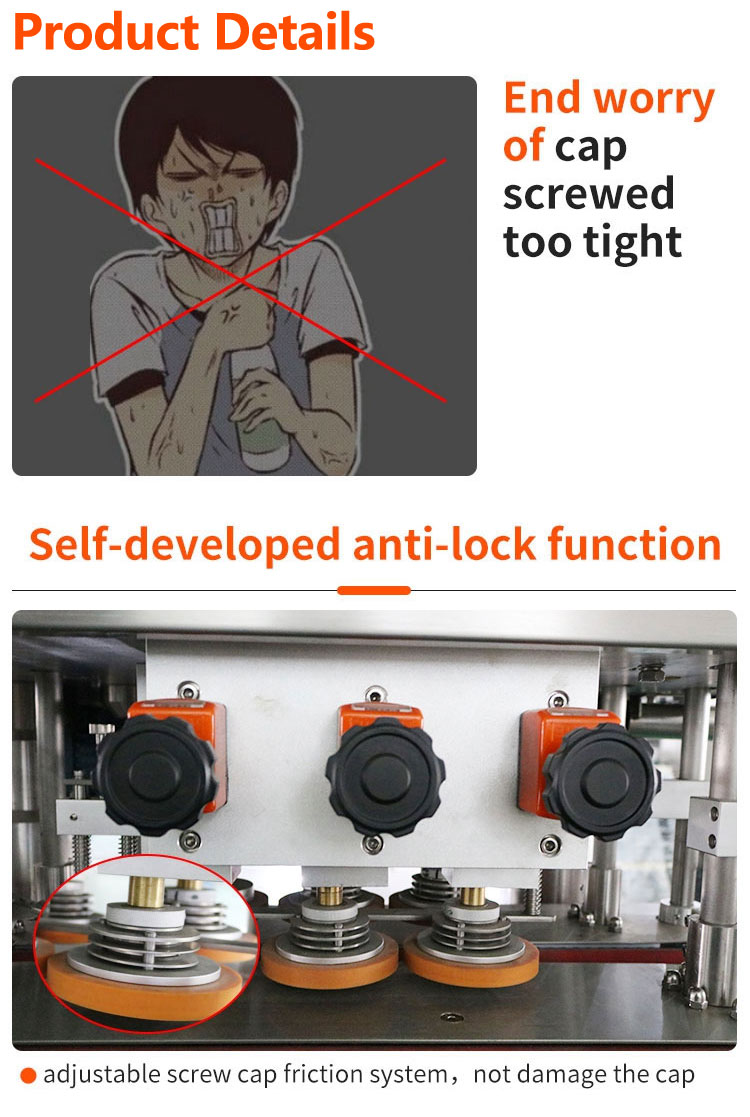

This capping machine RQ-XGJ-200 is composed of several parts: the feeding device of automatic lifting platform, the cap conveying track, the several photoelectric eye units for detecting cap supply, the roller hammer for extruding cap, the three rotating wheels for tightening cap, the PLC control panel with simple operation, the detection head for detecting whether there is aluminum foil, and the intelligent device for eliminating waste products and etc.

The workflow progress is that the required material bottle caps are sorted out by the material box, the mouth of the lid is fixed upward, and the reverse lid will return to the counting material box from the waste channels.

The bottle’s cap is continuously transported to the preset places through the conveying track, and will synchronously run to the bottom of the pressure wheels hammer with the bottles. These bottle caps are tightened by the three rotating wheels, and ill finally pass through the monitoring point to complete the process of capping.