DPP-260S In Stock 3 Years Warranty Automatic Packaging Honey Butter Oil Sauce Jam Blister Packing Machine

DPP-260S | |

Production Capacity | 2400-9600 pellets per hour |

Max. Shaping Dia. And Depth | 250*140*15mm Max. Depth 26mm(custom-made) |

Blanking | 10~45 times/min |

Power of Main Motor | 2.2kW |

Total Power | 8.5kW |

Power supply | 380V/220V/50Hz |

Standard Travel Range | 40~185mm |

Standard Plate | 80*57mm |

Thickness and Width of PVC | 0.15~0.5*120mm |

Thickness and Width of PTP | 0.02~0.035*120mm |

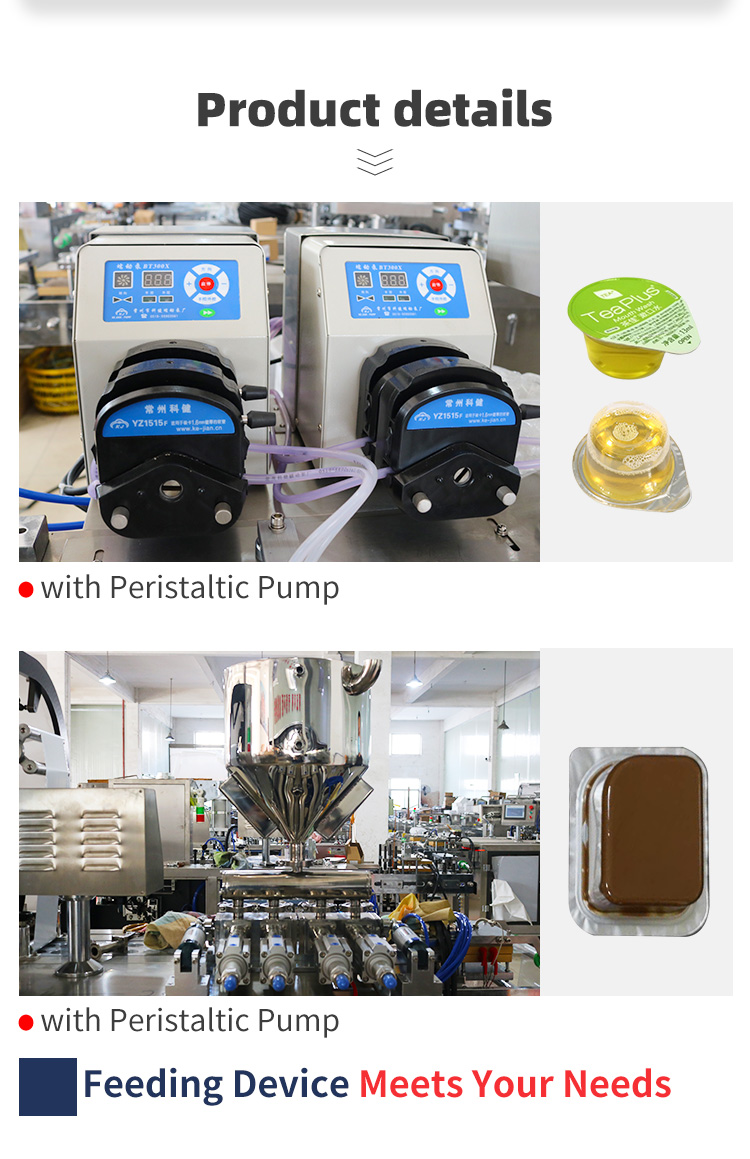

This DPP-260L packaging blister packing machine is improved from the blister bubble packaging blister packing machine for packing solids things. Our Rich Packing company transformed the material feeder at the front end of the machine into a specially feeder for adding liquid or the oil-like substances. So DPP260L can be used for fish oil, ketchup, honey, butter and the other liquids to be placed into the PVC and Alu blister boards.

What kind of the special liquid material feeder used in dpp260L. DPP260L is suitable for all kinds of liquid and the suspension materials to produce by these machine. DPP260L’s servo motor is more better and can be running stably. Dedicated the PVE rolling feeding device of dpp-260L. It through the system control of gas steel valve inflation and will deflate to achieve a very simple PVE feeding.

Why should choose RichPacking’s DPP260L packaging blister packing machine? Because the outer packing material of DPP260L can be composed by the PVC plastic and aluminum foil, or Alu and ALU foils together. To finish the production of blister packing by changing different packaging material, users only need to place different outer packaging materials into the feeder. The feeder in 260L is different from the brush feeder or the guideway feeder for solid feeders.