ZP 51 99D Ultra High Speed Automatic Pharmaceutical Rotary Tablet Press

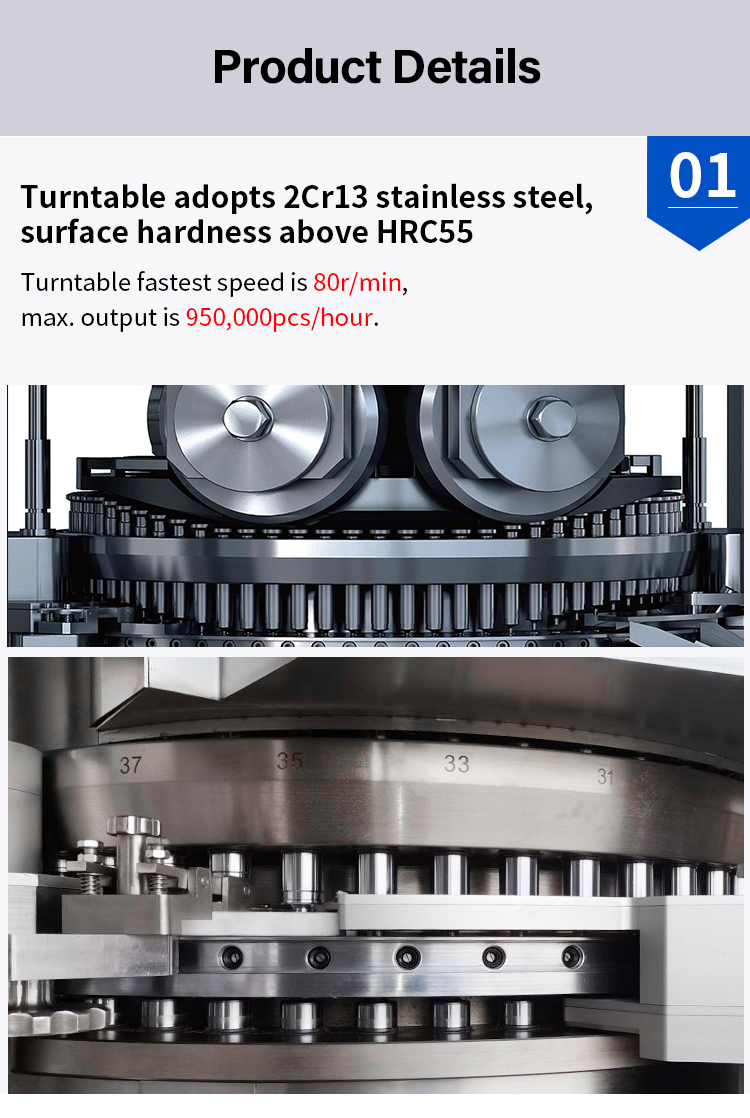

Model | ZP-51D | ZP-65D | ZP-83D | ZP-99D |

Dies No. | 51 | 65 | 83 | 99 |

Max. Pressure | Main 150 kn,Pre 150 kn | |||

Max. Dia. of Tablet | 25 mm | 16 mm | 13 mm | 10 mm |

Max.Depth of Filling | 20 mm | 18 mm | 18 mm | 18 mm |

Max.Thickness of Tablet | 1-8 mm | |||

Rotary Speed r/min | 10-80 | |||

Max. Production Capacity pcs/hour | 470,000 | 620,000 | 790,000 | 950,000 |

Power | 11 kw | 11 kw | 11 kw | 11 kw |

voltage | 380 220V/50Hz | 380 220V/50Hz | 380 220V/50Hz | 380 220V/50Hz |

size | 1310*1305*2010 mm | 1310*1305*2010 mm | 1310*1305*2010 mm | 1310*1305*2010 mm |

Weight | 5510 kg | 5510 kg | 5510 kg | 5510 kg |

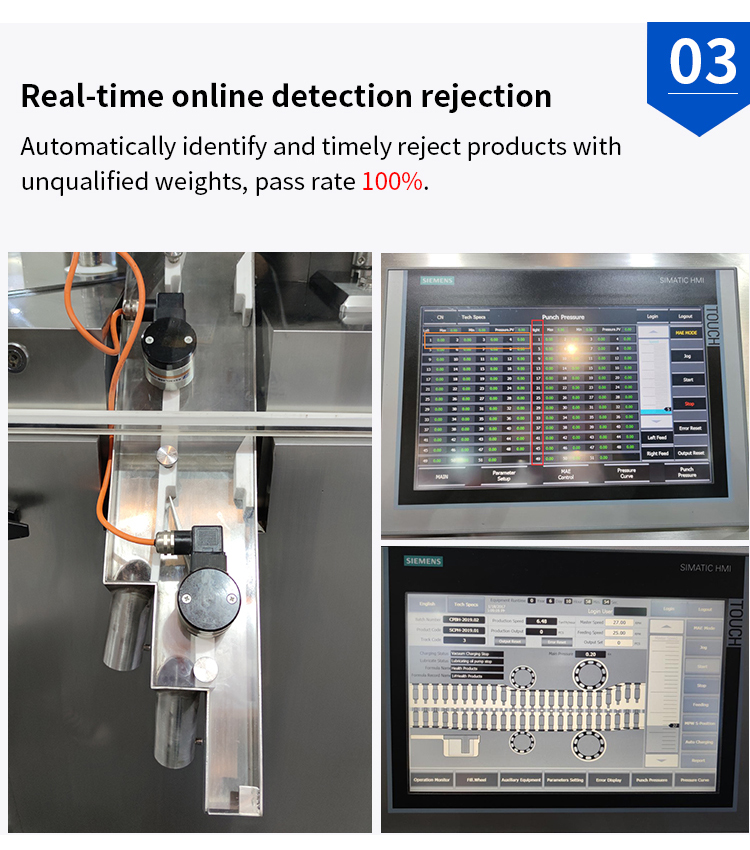

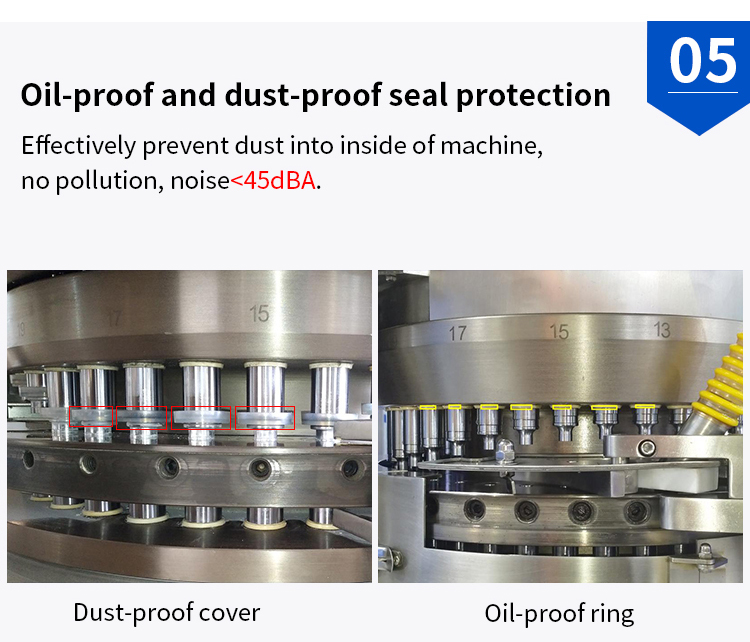

High pressure zp-51 / 99D ultra-high speed rotary tablet press can press all kinds of tablets, health products, washing tablets, effervescent tablets, camphor pills and other tablets. Moreover, this tablet press 51 / 99D has the function of forced feeding and extremely stable tablet weight, and can control the weight error of the average tablet within 2%.

As an excellent supplier of the world's top 500 and a gold medal merchant of Alibaba, Rich packing machinery company has always adhered to the principle of integrity and customer demand, maintained products at lifelong cost price, and guaranteed direct refund in case of quality problems. Therefore, Rich packing company, which has 6517 foreign trade customer service experience, can also provide professional customized high-speed rotary tablet press services, technical service materials, etc. it is hereby that the customer repurchase rate exceeds 64%.

It only takes 20 minutes to install the 51 / 99D die of the high-speed rotary tablet press. Before installing the die device, first disassemble the lower hopper, feeding frame, feeder and other components, then align the die on the turntable with the outer circle of the turntable one by one, and then check that the upper die head enters the middle die up and down, and rotate flexibly. After the main body is installed, open the round tab from the main body and then install the die. After all dies are set and installed, let the machine run in trial (idle for two or three minutes). After the machine is stable, it can be put into normal production.