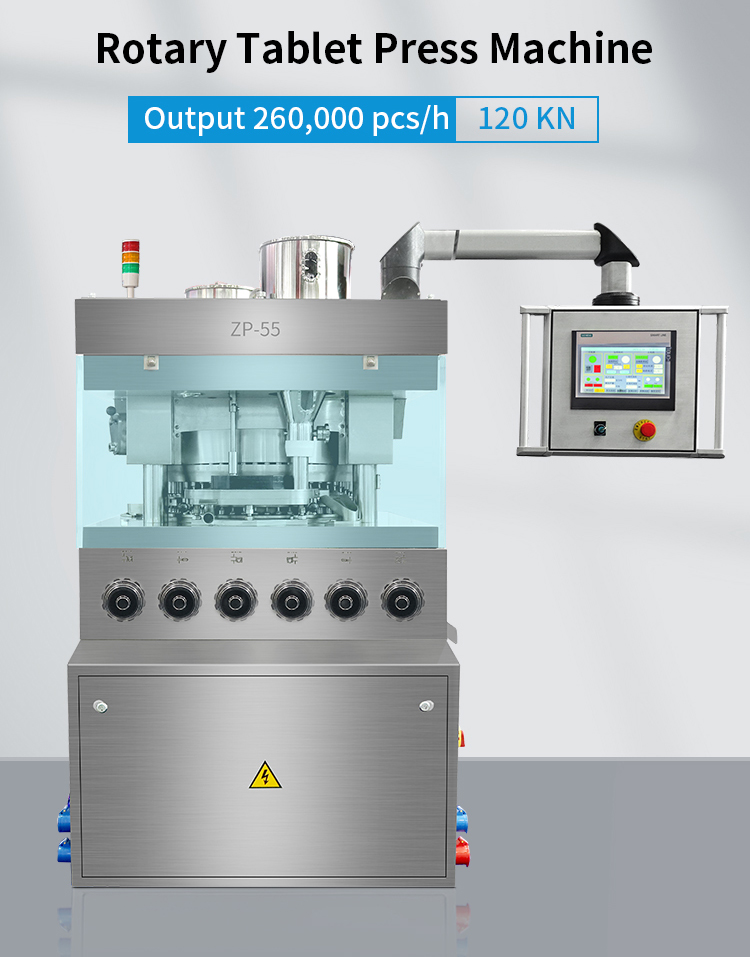

ZP-41/55 Automatic Pharmaceutical Rotary Tablet Press Machine

Model | ZP-55 | ZP-51 | ZP-41 |

patent | Casting subtraction structure patent | ||

Capacity | 260000pcs/h | 220000pcs/h | 160000pcs/h |

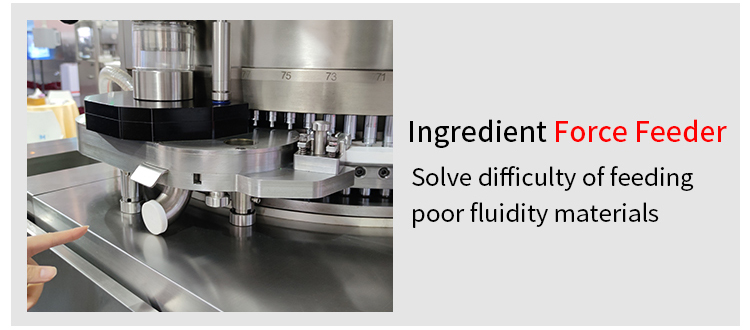

Applicable material | Powder,granule | ||

Applicable tablet types | round tablets, special-shaped tablets, double color and annular tablet. | ||

Max. pressure | 120KN | ||

Max. tablet diameter | 13mm | 19mm | 25mm |

Maximum press thickness | 8mm | 9mm | 9mm |

GMP requirements | The main body adopts stainless steel 304, All the contacting parts of the tablet press meet the requirements of "no poison, no odor and corrosion prevention". | ||

Precision | The hole of upper punch, lower punch and middle mold, the axis of outer circle to the center of the shaft hole coaxiality is H8 (-0.165/0). The sensitivity of the hand wheel is 0.1mm. | ||

Power supply | 380/220V/50Hz | ||

Power | 7.5kw | ||

Weight | 2000kg | ||

Outline dim. | 1220×1120×1850 mm | ||

Packing/size | Standard export wooden case/1600×1300×2160mm | ||

Warranty | two year | ||

Method of Warranty | Remote telephone and video guidance or home service according to customer requirements | ||

Time of delivery | Shipped in 15 days after payment | ||

Payment term | L/C,T/T,Western Union | ||

Port of loading | Guangzhou or Shanghai | ||

The multi punch tablet machine is a fourth generation double automatic rotary tablet press that can continuously press powder and granular materials into circular, circular, double color and special-shaped tablets. It is easy to make and has high pressure. It is a suitable model for pressing and molding materials. It is also the first choice for large-scale production in food, electronics, chemical, pharmaceutical and other enterprises, and meets the GMP production requirements.

The common machine parts such as the mold and feed hopper of the tablet automatic rotary tablet press are easy to disassemble (the replacement of the mold is completed within 1 hour), easy to clean and easy to maintain. The particle full-automatic rotary tablet press has high configuration, strong performance of core parts of the whole machine, good machine stability, long service life and low failure rate.

Pharmaceutical full-automatic tablet press is suitable for pressing pharmaceutical pills, health care tablets, etc. the tablet weight of the automatic tablet press is stable (the machine's upstroke cosine curve moves without jumping), the precision is high, the adjustment is sensitive, and the operation is more stable. The product of automatic rotary tablet press is structured and modularized. The drive system is independently and modularized under the main body of the machine, which effectively avoids the contamination of drugs by trace impurities generated by machine friction.