CGN-208 Semi-automatic Pharmaceutical Capsule Filling Machine

Warranty | 3 Year/36 Months |

After-sale | Engineers available to service machinery overseas |

Product Name | Semi Automatic Capsule Filling Machine |

Type | Capsule Filling Machine |

Applicable Capsules | # 000/00/0/1/2/3/4/5 |

Filling Material | Powder/Tablet/Pill/Pellet |

Material | Stainless Steel |

Power Supply | 380/220V 50Hz |

Total Power | 2.12kw |

Capacity Of Air Compressor | 0.1 m³/min |

Function | Empty Capsule Filling |

Application | Health Care Products/Hospitals/Laboratories |

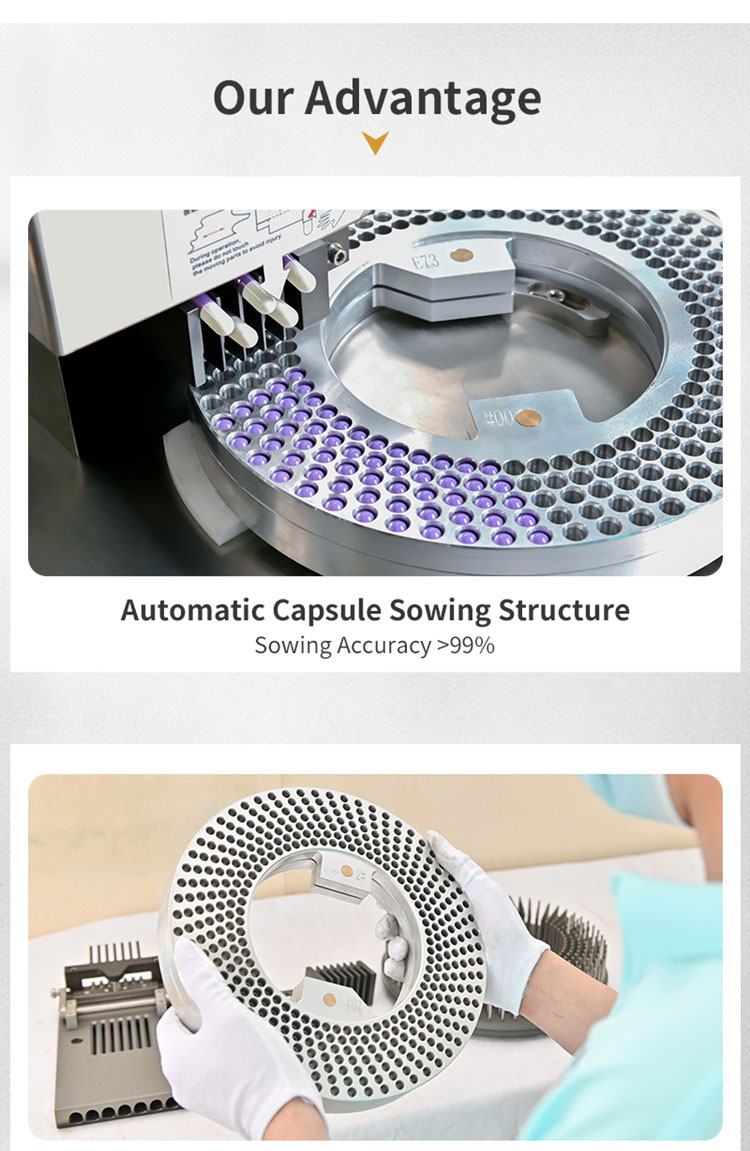

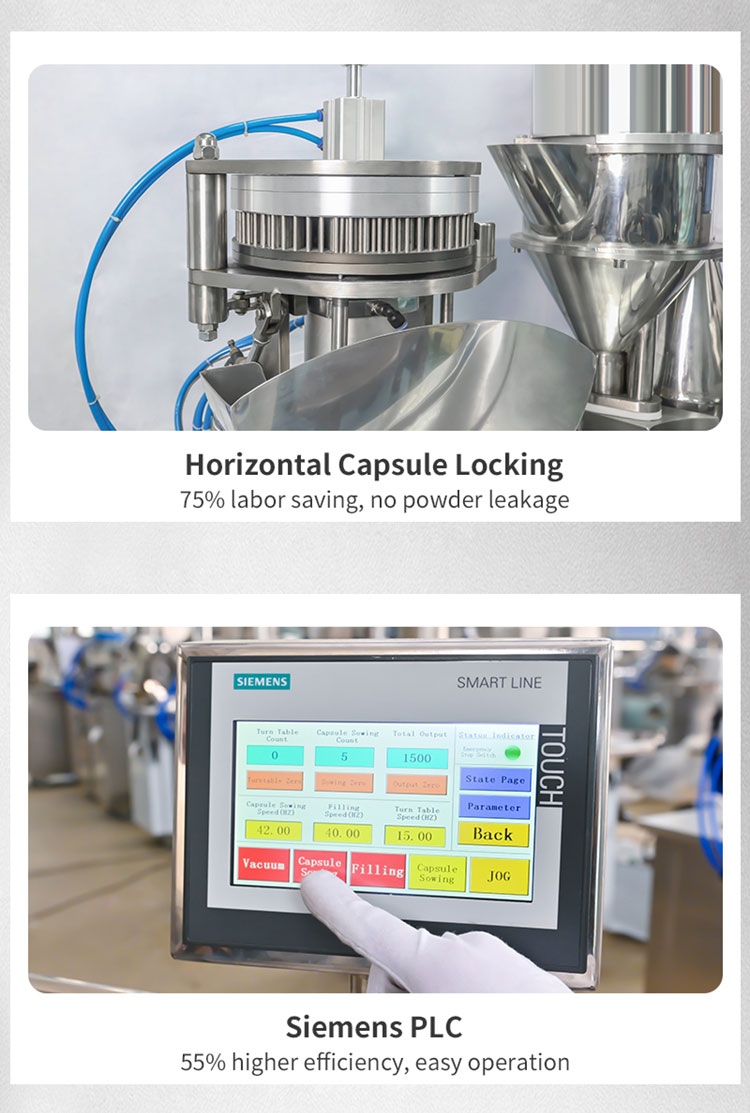

CGN-208 semi-automatic capsule filling machine for pellets is a new type of semi-automatic capsule machine for filling small pieces, granules or powders into hard hollow capsules. The machine adopts touch panel operation, variable frequency adjustment speed, pneumatic joint control, and electronic automatic counting device of the machine, which is easy and safe to operate.

The semi-automatic capsule machine CGN-208 adopts a scientific and new horizontal capsule locking mechanism, which can effectively avoid the leakage of herbal powder during the capsule locking process, thereby improving the utilization rate of raw materials and filling accuracy; Fully paste the principle of full capsule, the capsule will not be damaged when the capsule is locked, which greatly improves the yield.

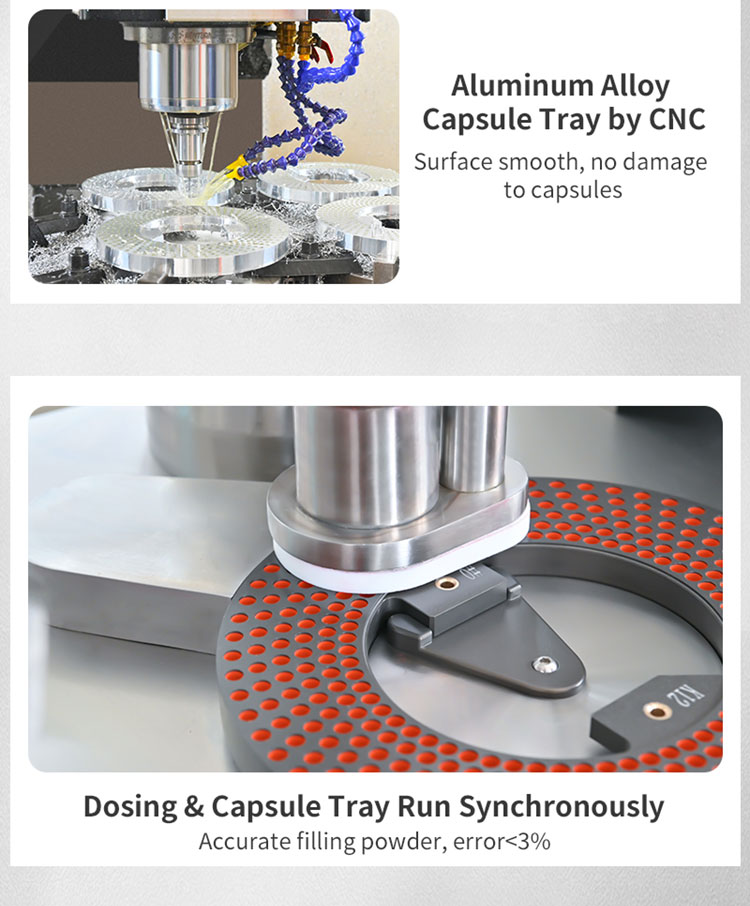

The powder semi-automatic capsule filling machine adds a user-friendly and quick filling button below the machine (anti-accidental double verification lock bag, emergency stop switch), which can realize the metering adjustment function by controlling the powder filling speed. The filling amount is accurate and the error is less than 3 %. The small-piece semi-automatic capsule machine with the transmission mechanism connected by a screw only needs to eject the screw, move the hopper, and remove the screw of the hopper to easily replace the filling material and clean the remaining material.