DPP-160Pro Aluminum Plastic Blister Packaging Machine

model | DPP-160Rro |

Number of punching | 20-50/min |

production capacity | 36000-72000pcs/h |

main motor power | 1.1kW |

total power | 5.5kW |

power supply | 380V/220V/50Hz |

Noise index | <75dBA |

mold cooling | Tap water or circulating water |

machine weight | 1600 kg |

Dimensions | 2670×600×1530 mm |

Here are the advantages of the modular design in the DPP-160pro:

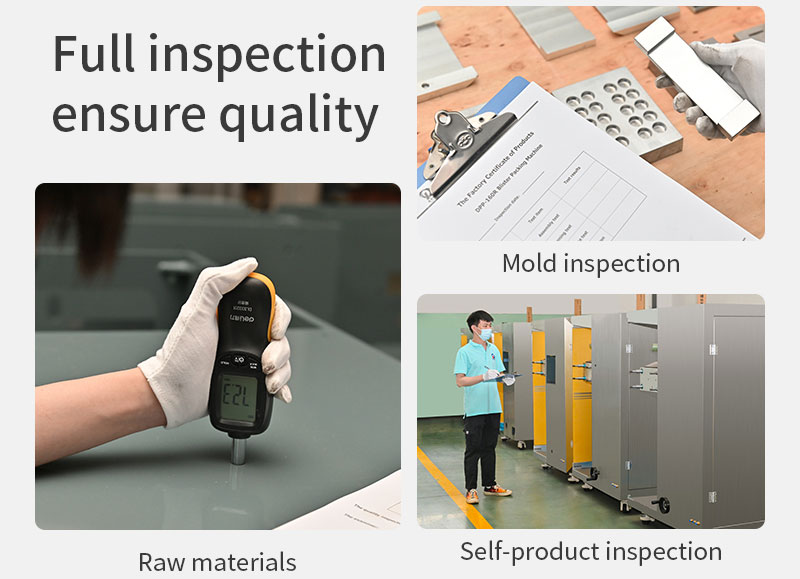

Ease of Maintenance: The modular design simplifies maintenance and troubleshooting procedures. Each module of blister machine can be independently accessed, inspected, and serviced. If an issue arises, only the affected module needs to be addressed, minimizing downtime and reducing maintenance costs. Moreover, modules can be replaced or upgraded individually without impacting the entire machine's functionality.

Enhanced Efficiency: Modular design improves production efficiency. As modules can be adjusted or added, it enables different operations to be performed concurrently, such as blister forming, product filling, and sealing. This parallel processing capability maximizes throughput and reduces production time, enhancing overall efficiency.

Reduced Changeover Time: The DPP-160pro's modular design significantly reduces changeover time between different products or packaging formats. By swapping or adjusting specific modules, the machine can accommodate various blister sizes, cavity counts, and sealing methods. This quick changeover capability minimizes downtime during product changeovers, increasing productivity.

Upgradability: With a modular design, the DPP-160pro can be easily upgraded to incorporate new technologies or meet evolving regulatory requirements. Upgrading specific modules allows for the integration of advanced features, such as improved automation, enhanced inspection systems, or upgraded control systems, ensuring the machine stays up-to-date with industry advancements.

Cost Savings: The modular design offers cost-saving benefits. Instead of replacing the entire machine when specific requirements change, only the necessary modules need to be modified or replaced. This reduces capital expenditure and extends the machine's lifespan, resulting in long-term cost savings for the manufacturer.

In conclusion, the modular design of the DPP-160pro packaging blister machine brings multiple advantages. Scalability, flexibility, ease of maintenance, enhanced efficiency, reduced changeover time, upgradability, and cost savings are the key benefits that contribute to its superior performance and adaptability in various packaging scenarios.