DPP-110L-B Automatic Liquid Blister Packing Machine

Introduction

This machine is suitable for packing the liquid like chocolate,jam ,butter, honey widely used in food industry.

Main Features

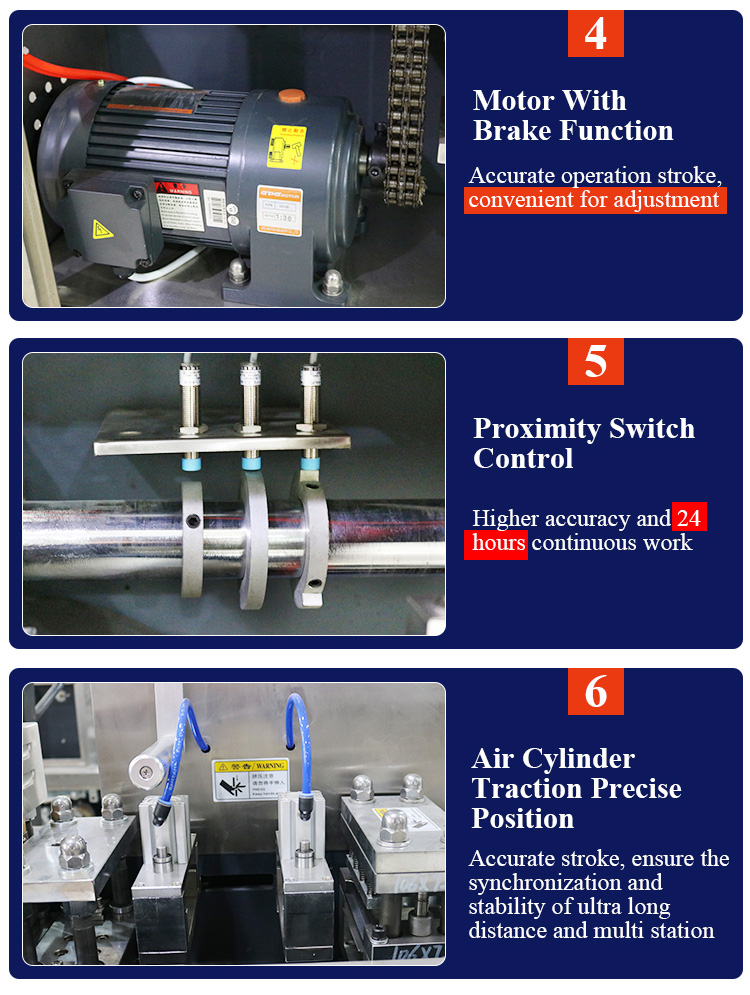

1.It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

2.Imported controlling system is adopted; also it can be equipped with detecting and rejection function device for number of medicines according to the user’s requirement.

3.The machine adopts separation sectional combination: PVC forming, Feeding, Heating sealing for one section; Tropical cold aluminum forming, Heating sealing and cutting for another one section for separately packaging.

4.It adopts photoelectrical controlling system to make PVC, PTP, be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

5.It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade

6.The machine is suitable for packaging of capsule, tablet, coating pills, syringes, medical instruments electronics and etc.

7.All of working stations are adopted four columns for position. It is with stability performance and easy operation.

8.It can add pressing station. It can be with total of four working stations of forming,sealing, pressing and cutting. It is widely suitable for all requirements of packaging.

9.It can add Waste edge device, The waste is in good consistent and clean after cut. It’s easy to clean.

10.Box body can be adjusted through swing type gear with level. It’s easy to adjust and check;PVC film roller is built-in,it's sealing and dust-free.

11. The hot sealing station adopts underneath type air cylinder. The pressure is average and clean appearance;and the indentation device is option.

12. Water inlet, outlet and air inlet(should connect with the air compressor and

Workflow:

Blister forming---Heat sealing---Printing code---Embossing---Puching---Finished products

Technical Parameter

Model | DPP-110L-B |

Punching frequency | 10-35 Times/min. |

Production capacity | 2400 Pcs/H |

Max.forming area,depth | 70*110*26mm |

Standard travel range | 20-80mm |

Standard blister size | 80*57mm |

Air supply | 0.6-0.8Mpa |

Total power | 380V 50Hz 3.0Kw |

Main motor power | 0.75Kw |

PVC sheet | Thickness(0.15-0.5)*Width110mm |

PTP | Thickness (0.02-0.035)*110mm |

Dialyzing paper | (50-100)g*110mm |

Cooling mould | Running water,Circulation water |

Overall dimension | 1500*600*1200mm |

Weight | 450Kg |

Noise | <75dBA |