Introduction

DPP-110 is a special kind of machine automatically packing tablet,capsule,candy,electronic cigarette,perfume and tomato sauce,soft capsule, big honeyed pill and injection into aluminum plastic composite panel(ACP) or aluminum plate.It is the preferred machine possessing fully automatic shaping,adding,sealing and blanking, which is the preferred products for small and medium sized production in pharmaceutical manufacturing, chemical industry, electronic products and food industry, it meets the requirements of GMP.

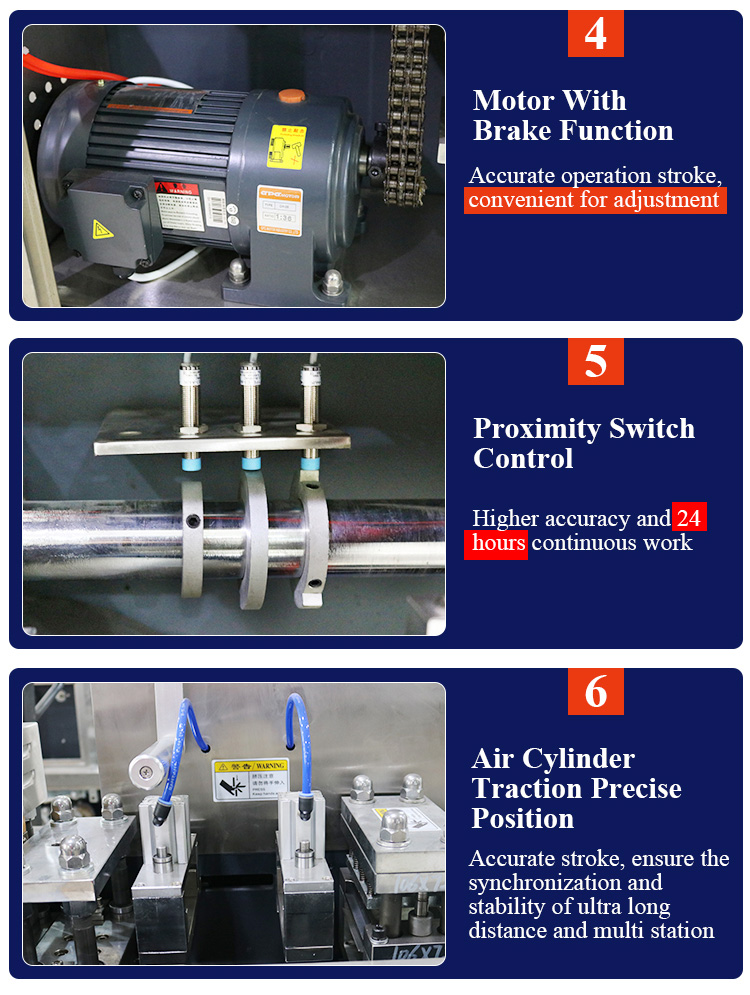

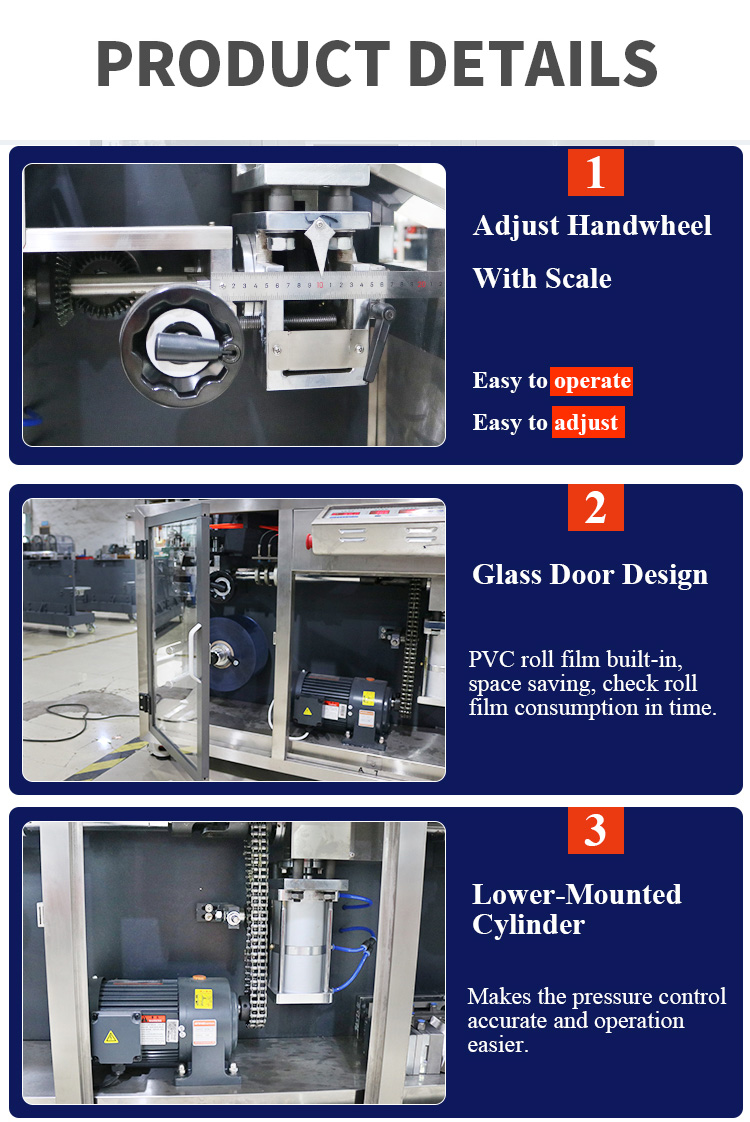

Main Features

1、Low runing cost and high cost performance for aluminum and plastic, or aluminum and aluninum.

2、Wide material suitable range,can sue PVC,PS and PET to produce.

3、 Adopt new type high power gear motor,stable operation.

4、Strand chain transmission, low noise, less than 75dBA.

5、Advanced control system and cylinder traction system, accurate travel,super-long distance multi-station synchronous stability.

6、Molding, traction, positioning module using proximity switch control instead of pneumatic control, higher accuracy, longer service life.

7、The electric appliance adopts the famous brand products and concentrates the modular design, which is convenient for maintenance.

8、Equipped with emergency stop device, can stop immediately when emergency.

9、Every stations adjustment adopts rotary handwheel and equipped with scales,convenient and precise.

10、Equipped with impressing device, can use easily.

11、Equipped with recovery device,improve production and keep the worekshop clean.It meets the demands of GMP.

12、Optional sealing ,optoelectronic detection system and the function graphic and text version, improve package level(optional).

Main Technical Parameters

Model | DPP-110 |

10~40 times/min | |

Production Capacity | 2400 plates/h |

Max. Shaping Dia. And Depth | 110*80*15mm Max. Depth 25mm(custom-made) |

Standard Travel Range | 30~80mm |

Standard Plate | 80*57mm |

Power of Main Motor | 0.75kW |

Total Power | 2.4kW |

Power | 380V/220V/50Hz |

Vacuum | 0.6MPa-0.8MPa |

Noise | <75dBA |

Thickness and Width of PVC | 0.15~0.5*120mm |

Thickness and Width of PTP | 0.02~0.035*120mm |

Dialyzing Paper | 50~100g*120mm |

Mold Cooling | Runing water or circulating water |

Weight | Net weight 590 kg ;Gross weight 650 kg |

Overall Size of Machine | 1650*620*1250 mm |

Packing Size | 1850*800*1500mm |