Our automated pill blister pack packing machiner can fully automatically feed and pack pills,hard gel capsules or softgel cap,and also can pack e-cigarette,Medical accessories (Dental swab stick inject injection syringe) by manual feeding

Model of blister pack packing machine | DPP-260R |

Production Capacity of blister pack packing machine | 18000~236,000 pcs/hour |

Max. Shaping Dia. And Depth | 250*160*15mm Max. Depth 26mm(custom-made) |

Blanking of blister pack packing machine | 20~180 blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

Power of Main Motor of blister pack packing machine | 1.5kW |

Total Power of blister pack packing machine | 6.0kW |

Power supply of blister pack packing machine | 380V/220V/50Hz |

Standard Travel Range | 40~160mm |

Standard Plate of blister pack packing machine | 80*57mm |

Thickness and Width of PVC of blister pack packing machine | 260*0.15~0.45mm |

Thickness and Width of PTP | 260*0.02~0.03mm |

Dialyzing Paper of blister pack packing machine | 50~100g*260mm |

Vacuum of blister pack packing machine | 0.4MPa-0.6MPa |

gas consumption of blister pack packing machine | ≥0.2m3/min |

Noise of blister pack packing machine | <75dBA |

Mold Cooling of blister pack packing machine | Runing water or circulating water |

Weight of blister pack packing machine | Net weight 2600kg |

Overall Size of blister pack packing machine | 3500*740*1680 mm(L*W*H) |

More details welcome click me or Follow the picture below to find the corresponding button and click

1. Newly designed servo motor press roller shaft traction, the traction will not have errors, the speed is fast and stable, and the packaging materials may retreat when the machine is stopped.

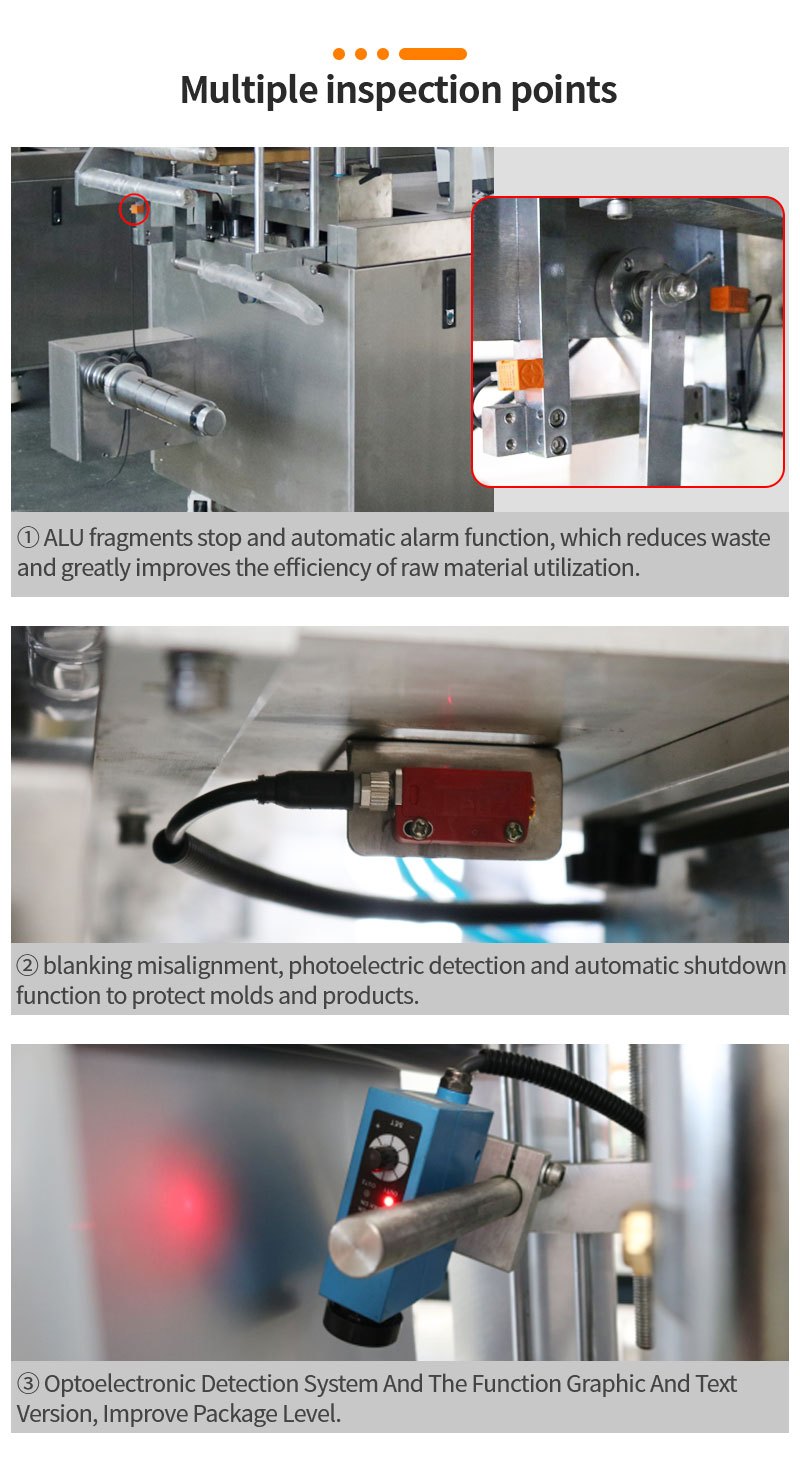

2. The cams of each station are all made of cast steel integrally formed floor box seat, which has large bearing capacity, will not be deformed, and the equipment runs stably.

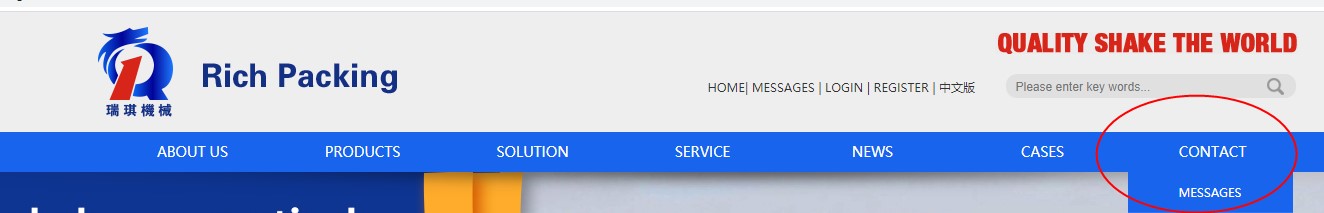

3.ALU scrap stop and automatic alarm, reduce waste and greatly improve the efficiency of raw material utilization.