item | specification | manufacturer |

Servo motor | ECMA-C20807RS | Taiwan |

server Driver | ASD-B2-0721-B | Taiwan |

PLC main module | CP1L-M30DR-A | Omron |

PLC temperature module | CP1W-TSOO2 | Omron |

PLC touch screen | 6AV6/648-0BC11-3AX0 | Siemens |

Encoder | ZSP3806-003G-1500BZ3-5-24F | United States Rip Ann Waco |

Main motor | RC series helical gear motor | Geer |

frequency | VFD015M21A | Taiwan |

Stainless steel plate | 304 316 | Korea,japan |

Switching power supply | NES-100-24 | Taiwan mingwei |

emergency button | XB2-BS542 | Schneider |

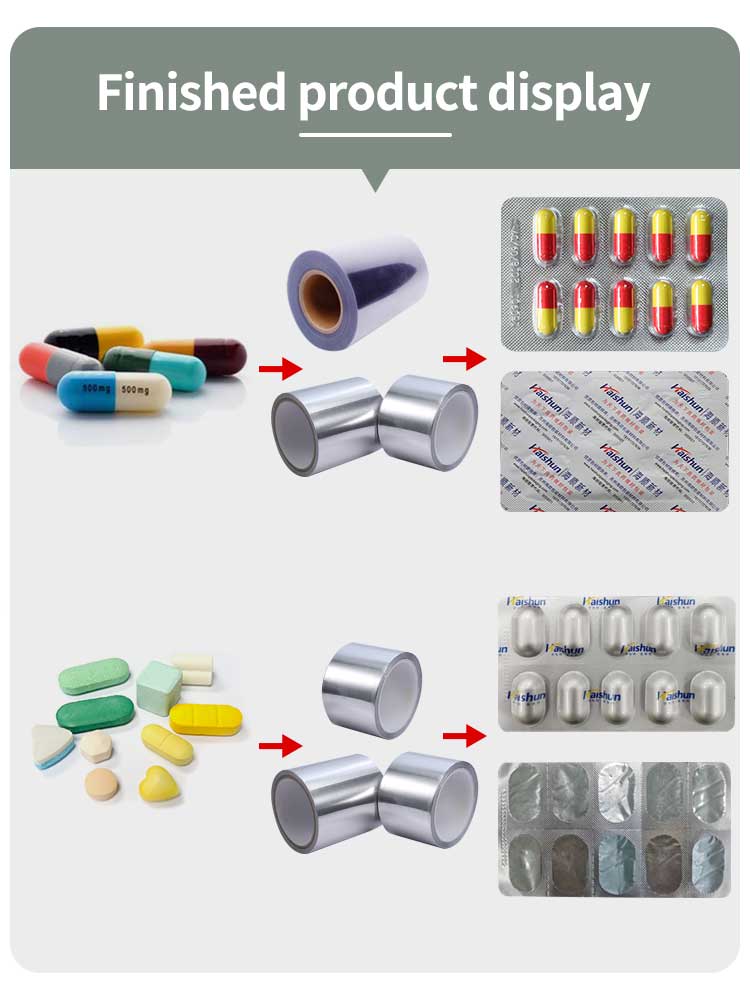

1. This type of blister packing machine has dual purposes of Aluminum-plastic and aluminum-aluminum and it is extremely low in operation cost and extremely excellent in performance.

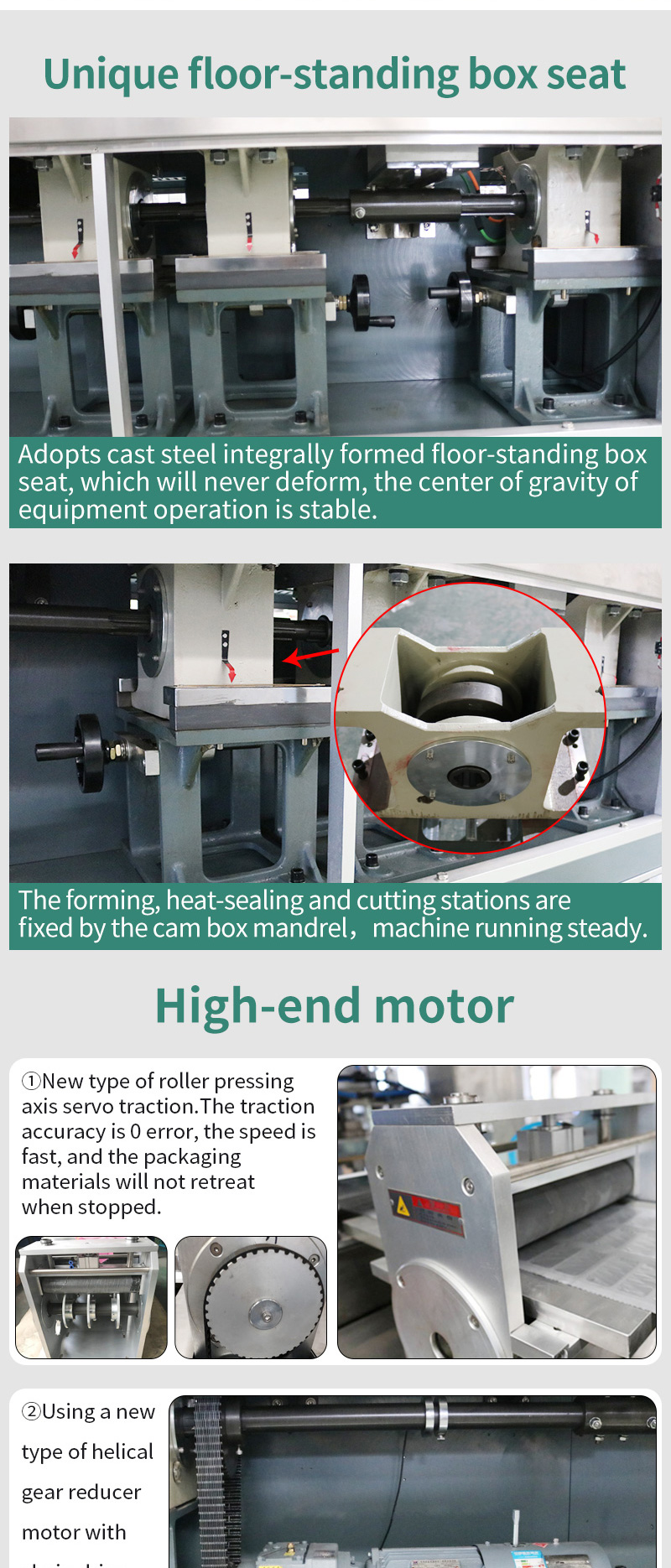

2. Blister packing machine will never retreat the packing materials when it stops and the operating speed is extremely rapid, it has traction accuracy of 0 error. And all these advantages due to its adoption of novel type of servo motor roller pressing shaft traction.

3. All parts of this blister packing machine including forming, heat-sealing and so on will never deform due to its adoption of cast steel uniformly formed floor-standing box seat. It is extremely stable in the gravity center of machine running and all the adjusts of all stations are extremely light and precise.

4. Blister packing machine 160R is extremely convenient for people to clean and maintain after finishing the whole process of product packing due to its extremely scientifically reasonable and large platform design.

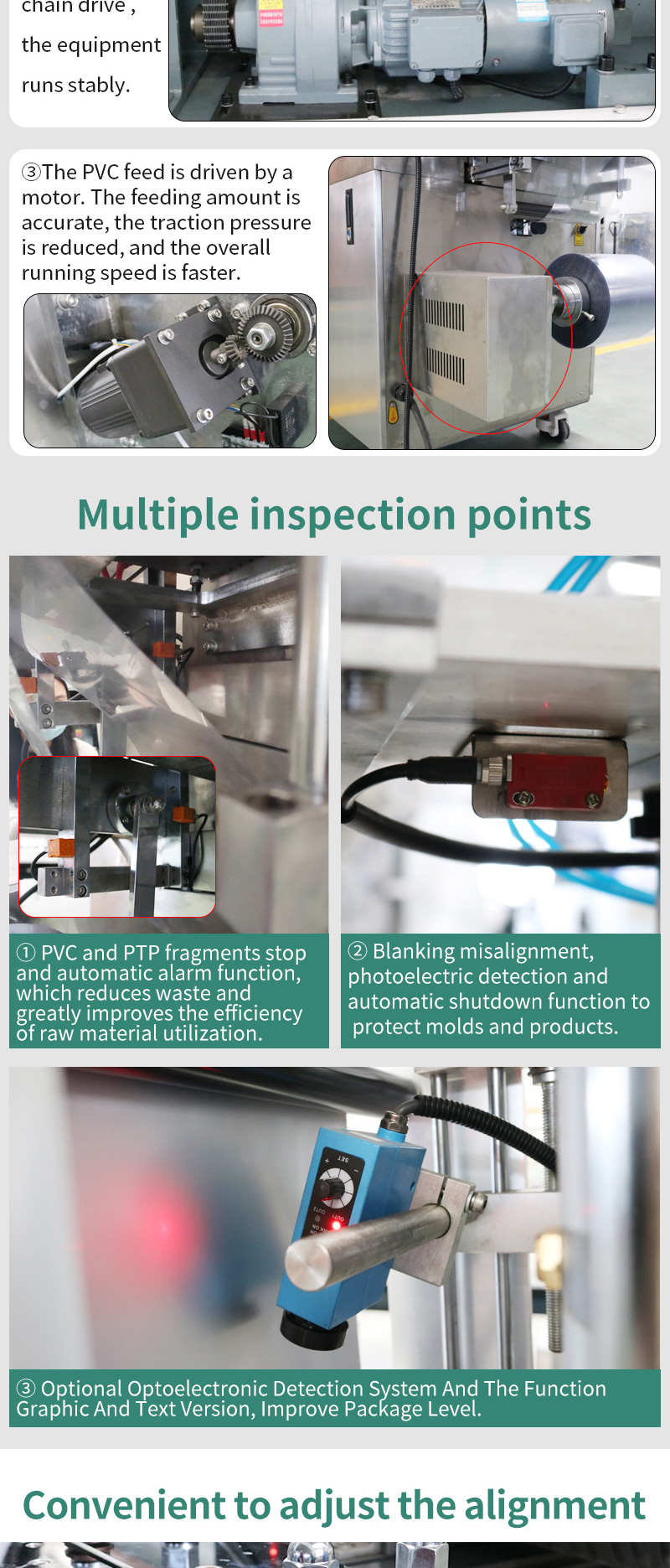

5. Blister packing machine 160R has the function of PVC and PTP fragments stop and automatic alarm to greatly reduce waste and efficiently improve the usage of raw material.

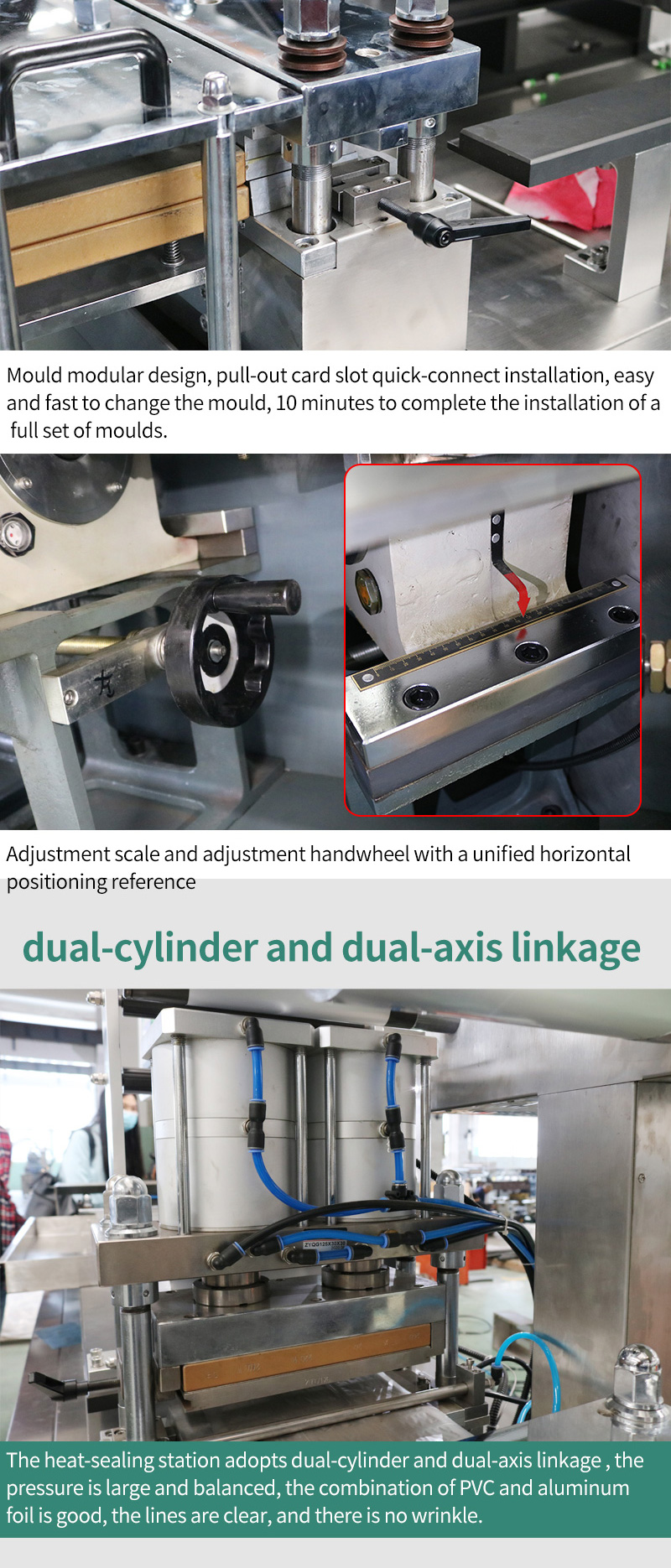

6. The mould is extremely easy to be changed and a full set of molds can be quickly installed within an extremely short time of 10 minutes.

7. All stations including forming, heat-sealing, and cutting are extremely safe for people to use because all of them are equipped with safety covers.

8. Molds and products can be well protected by the function of equipped blanking misalignment, photoelectric detection and automatic shutdown.