DPH-ZH-260W High Capacity Automatic Packaging Blister Carton Box Packing Machine

Technical parameter

Model | DPH-ZH-260W |

Production Capacity | Max 260 cartons/minute |

Max. Shaping Dia. And Depth | 250*160*15mmMax. Depth26mm(custom-made) |

Power supply | 380V/220V/50Hz |

Thickness and Width of PVC | 260×0.15~0.45mm |

Thickness and Width of PTP | 260×0.02~0.03mm |

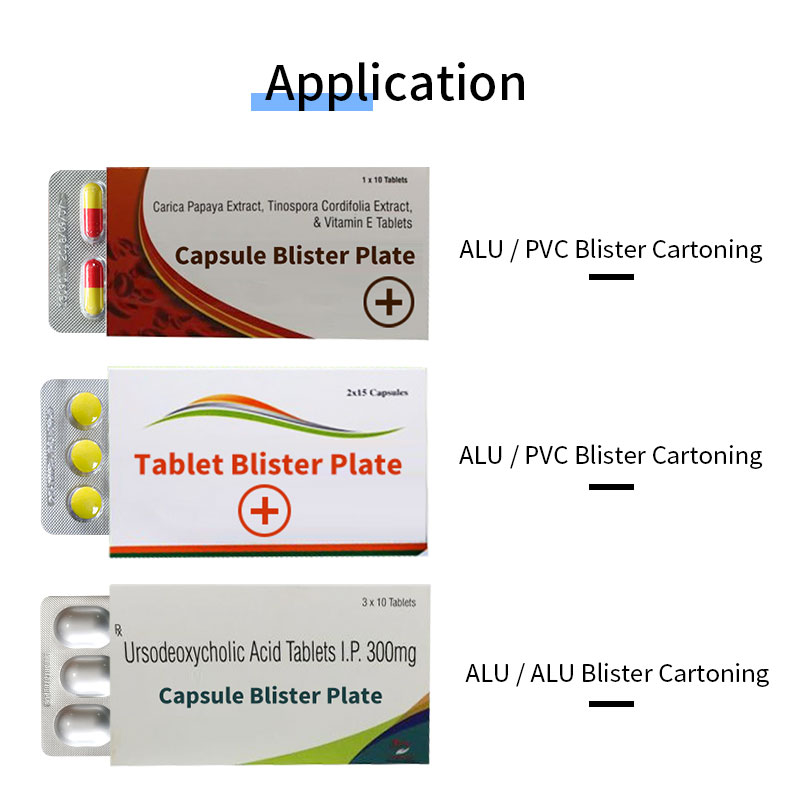

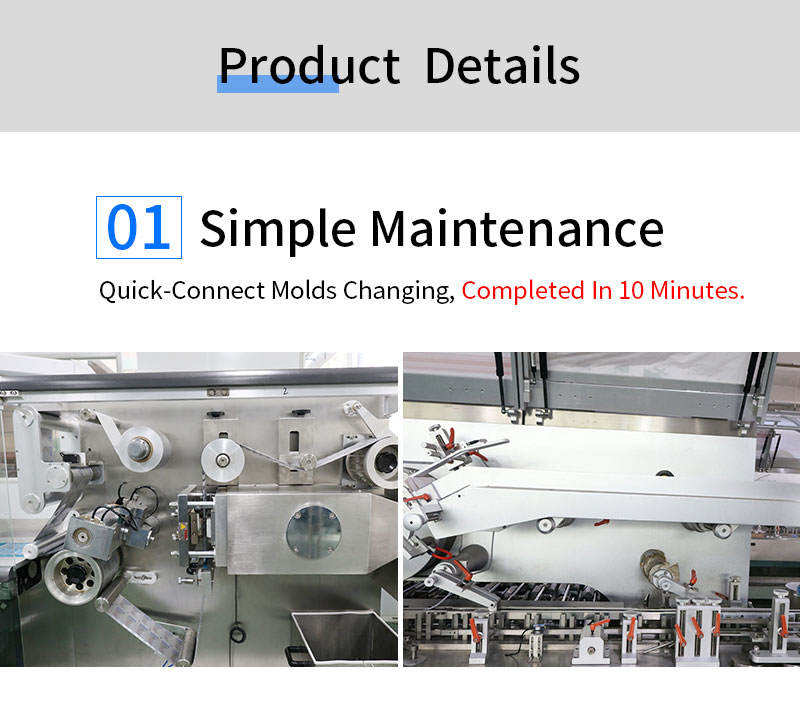

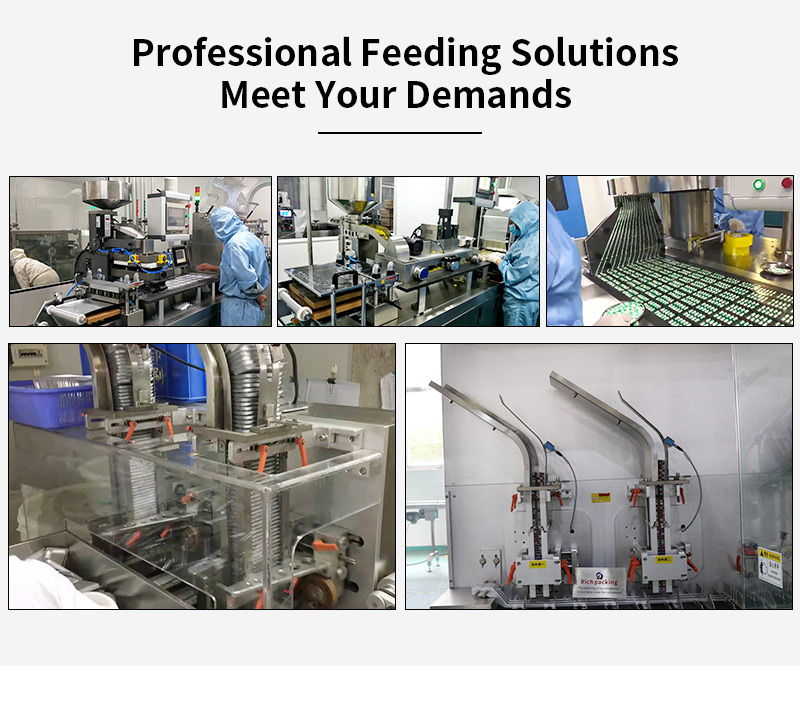

Dph-zh-260w high-capacity automatic packaging Blister carton packaging machine made of 316L stainless steel is a machine that meets the production requirements of cGMP. Because of the PLC intelligent screen control selected by the machine, the operation and maintenance of the packaging Blister carton packaging machine dph-zh-260w on the production line is also relatively simple. Therefore, it is the primary choice of many medium and large-scale production enterprises (pharmaceutical industry, food industry, packaging industry, etc.).

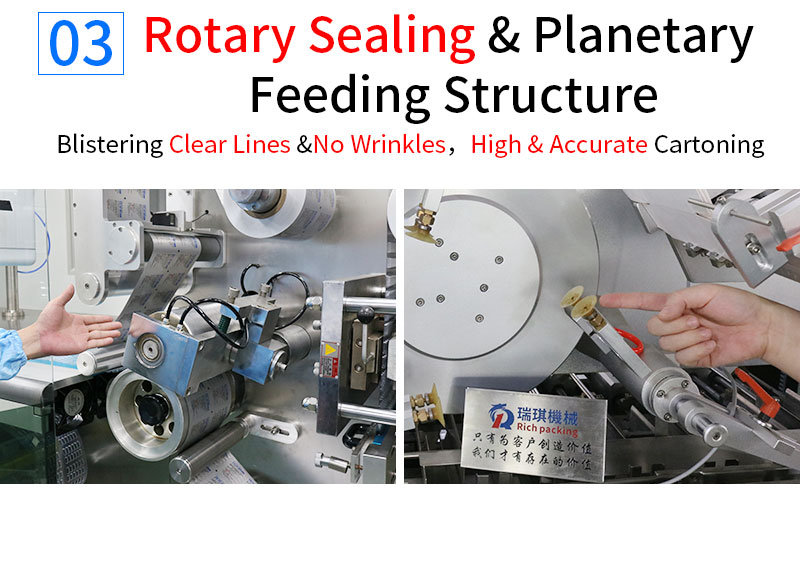

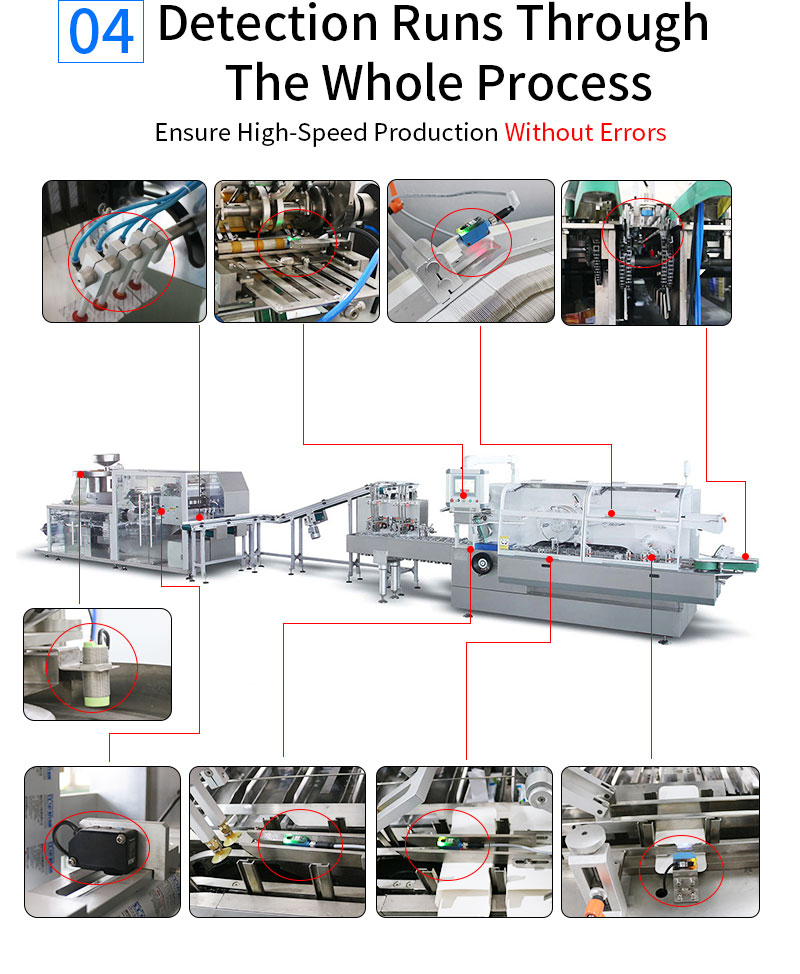

The packing and aluminum-plastic blister packaging of large-capacity automatic production line is a product with intelligent functions connected by two machines. Automatic packaging Blister carton packaging machine dph-zh-260w can intelligently complete various command operations (aluminum plastic packaging, material packaging, waste detection, tracking roller spider hand swing, blanking, automatic folding, image shooting, etc.), and this series of behaviors can accurately complete the production of materials and put them into the carton.

The high-capacity automatic packaging Blister carton packaging machine with servo motor traction 0 error has high module accuracy and more stable control in the three stations of forming, traction and positioning. The multifunctional glass protective covers of the two packaging machines can isolate the contact with the outside environment during production and operation, so it can also effectively keep the workshop clean during production. Adhering to the principle of customer first and one-stop service, the aluminum-plastic cartoning line is customized according to your actual needs, and the delivery period can be completed within 20 days at the fastest.

The automatic control system of this model (serial coded parts management and high-precision parts management) can reduce a large number of cumbersome manual operations, and greatly shorten the production cycle of the enterprise, so as to improve the production efficiency and product qualification rate. Dph-zh-260w aluminum plastic cartoning line, which can be delivered within 20 days at the fastest, has won a lot of customer support in the market for its overall production speed and product quality.