HOT PRODUCTS

Details

Home

> NEWS

> Industry News > Details

Home

> NEWS

> Industry News > Details

Solution To The Forming Problem Of The Blister Packing Machine

Solution to the forming problem of the blister packing machine

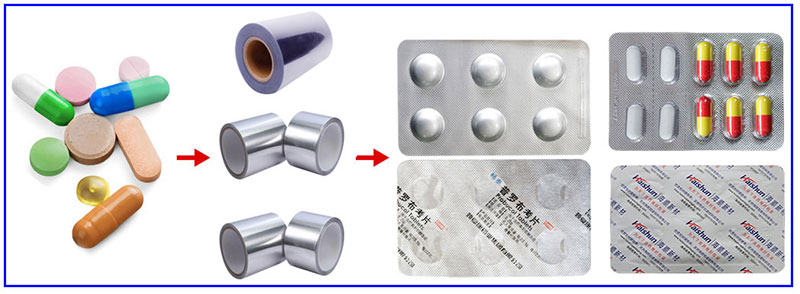

It is well known that bubble mask molding is the principle of PVC film (hard sheet) after heating through the mold, and using compressed air or vacuum molding for the required shape, size bubble. Therefore, when the formed bubble has problems∶ needs to be solved from these aspects

Is the PVC film (hard sheet) a qualified product; is the heating device temperature too high or too low;

Whether the surface of the heating device is attached to PVC;

Whether the molding mold is qualified, whether the molding holes are smooth, and whether the air holes are smooth; whether the cooling system of the molding mold works normal and effective;

Whether the vacuum degree and exhaust rate of the roller negative pressure forming can reach the normal value, and whether the pipeline has any abnormal loss;

Whether the compressed air formed by flat positive pressure is clean and dry, whether the pressure and flow can reach the normal value, and whether the pipeline is in abnormal loss;

Whether the plate positive pressure forming mold clamped the PVC belt in parallel and whether there is air leakage.