HOT PRODUCTS

Details

Home

> NEWS

> Industry News > Details

Home

> NEWS

> Industry News > Details

Advantages And Disadvantages Of Disc Brushing

Advantages And Disadvantages Of Disc Brushing

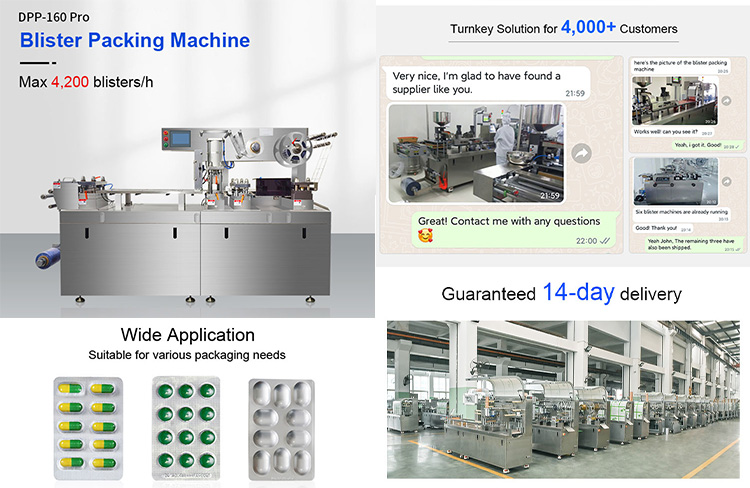

Today, the editor will introduce to you one of the most common feeding methods of blister packaging machines - disc brush feeding.

As the name implies, the disc brush feeding is to gently sweep the material into the prefabricated blister with a brush. Disk brush feeding has the following advantages:

1. Mature technology and simple manufacture. The whole feeder is composed of a disc brush, a roller and a governor, which is very simple and can be done by almost all factories;

2. Simple operation. The speed of the disc brush can be directly adjusted by the governor above;

3. Low cost of use. The main materials of the whole disk brush are stainless steel and brush, and the cost is relatively low;

4. Fast delivery, because of its low cost and mature technology, it can be quickly delivered to customers;

But the disc brush blanking also has its significant disadvantages:

1. If the speed of the disk brush is too fast, no tablets may be swept into some of the blister, resulting in the appearance of cavitation. Therefore, when the disk brush is running at a high speed, an inspector is usually required. When cavitation occurs, Timely manual replenishment;

2. The disc brush is suitable for relatively regular materials such as tablets and capsules, but it is not suitable for other materials with irregularities, and it is not suitable for materials with too small size.

If your material has a special shape or has special requirements for cutting, please contact Guangdong Rich Packing Machinery to customize it for you