HOT PRODUCTS

Details

Home

> NEWS

> Industry News > Details

Home

> NEWS

> Industry News > Details

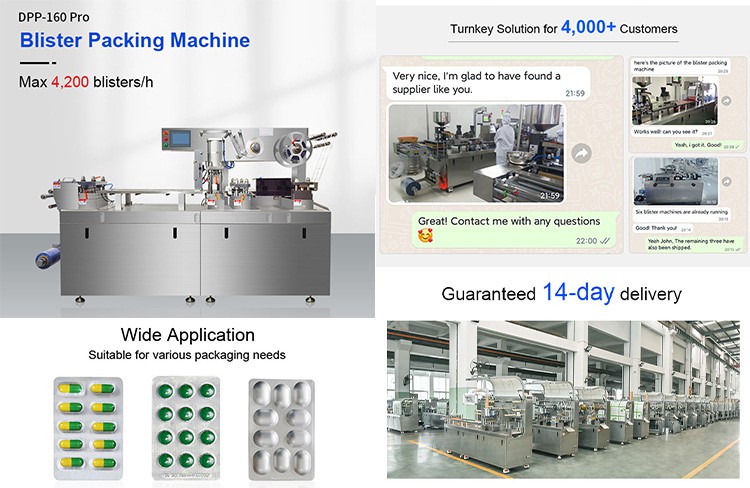

Development History Of Blister Packaging Machines

Development History Of Blister Packaging Machines

A blister packaging machine is a machine used to package products in transparent plastic blisters. The development process can be roughly divided into the following stages:

1. Manual packaging stage: The earliest bubble wrap packaging was completely manual, and workers needed to wrap the product with transparent plastic film and seal it with heat or glue, which was time-consuming and inefficient.

2. Semi automatic packaging stage: With the advancement of technology, semi-automatic bubble wrap packaging machines have emerged. This machine can automatically cut and package transparent plastic film, but it still requires manual placement and sealing of the product in the machine.

3. Fully automatic packaging stage: With the development of automation technology, fully automatic bubble wrap packaging machines have emerged. This aluminum plastic blister machine can achieve fully automatic forming, feeding, heat sealing, and product cutting, reducing manual operations and improving packaging efficiency and consistency.

4. High speed and efficient packaging stage: With the increase of market demand, aluminum plastic packaging machines continue to undergo technological improvements, improving packaging speed and efficiency. Nowadays, some high-end flat aluminum plastic blister packaging machines can achieve the packaging of hundreds or even thousands of products per minute, ensuring the quality and stability of the packaging.

5. Personalized customization packaging stage: In recent years, with the rise of personalized customization trend, automatic blister machines are also developing in this direction. Some new automatic bubble wrap packaging machines can automatically adjust the size and shape of the packaging according to the size and characteristics of the product to meet the packaging needs of different products.

Overall, the bubble wrap packaging machine has gone through a development process from manual to semi-automatic to fully automatic, from the initial manual packaging stage to the current high-speed, efficient, and personalized customization packaging stage, continuously improving packaging efficiency and quality, while also increasing functional diversity and flexibility.