CE GMP Full Automatic High Speed 2600C NJP Pharmaceutical Capsule Filling Machine

Production capacity | 150000 pcs/h |

Net weight of machine | 1500Kg |

Overall size of machine | 1100×1200×2000mm |

Power | 380/220V 50Hz |

Total power | 7.4KW |

No.of segment bores | 18 |

Vacuum | 63m3/h-0.04-0.08Mpa |

Dust collector | 24.5Kpa 210m3/h |

Noise | <75DB(A) |

Making rate | Empty capsule 99.9% Full capsule 99.8% |

Applicable capsule | 000,00,0,1,2,3,4,5# |

Filling error | Western medicine:±3% Chinese medicine:±4% |

Applicable product | Power、granule、pellet、tablet |

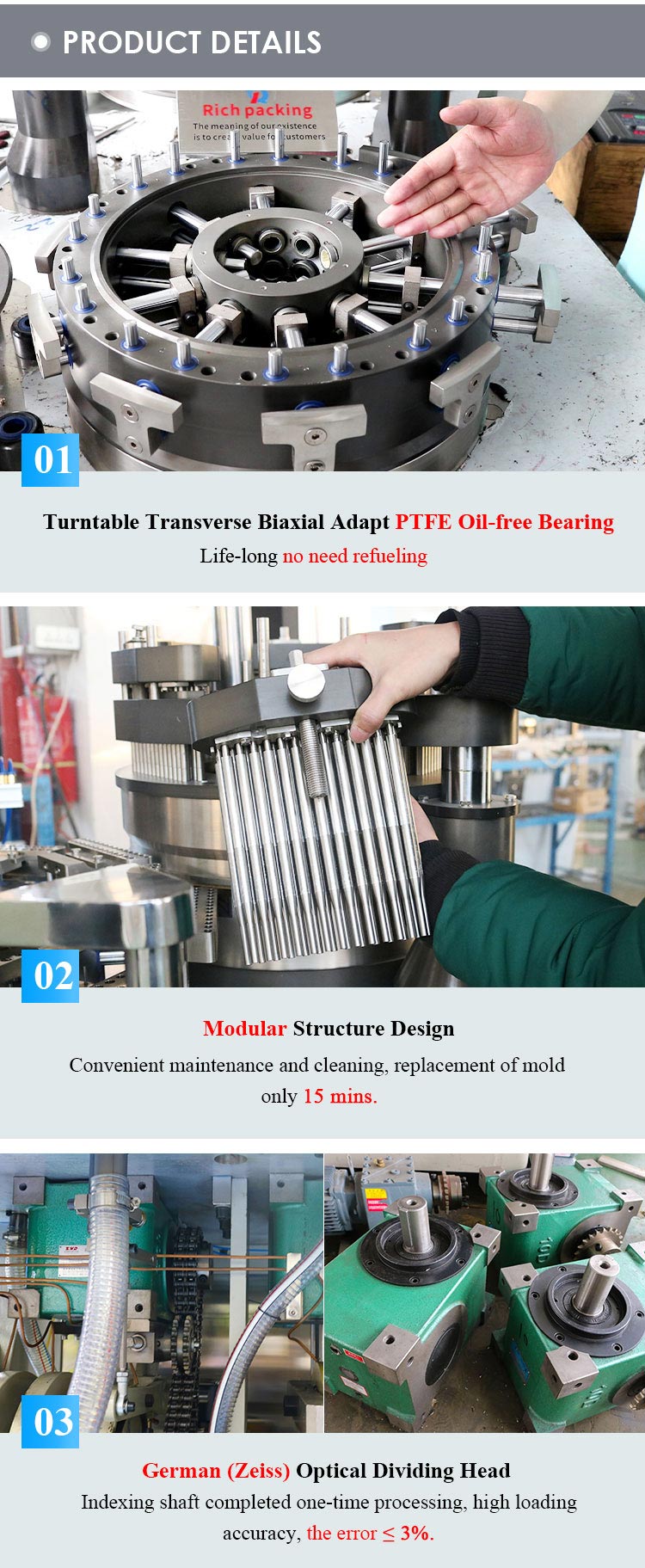

The rotary design of high-speed full-automatic pharmaceutical njp2600c capsule filling machine has obtained the national patent of utility model. 2600C medicinal capsule filling machine the sealing ring of this product is imported SIL silicone rubber, which has good sealing performance, and can effectively prevent powder from entering the turntable, so that the machine is free of dust and overflow pollution.

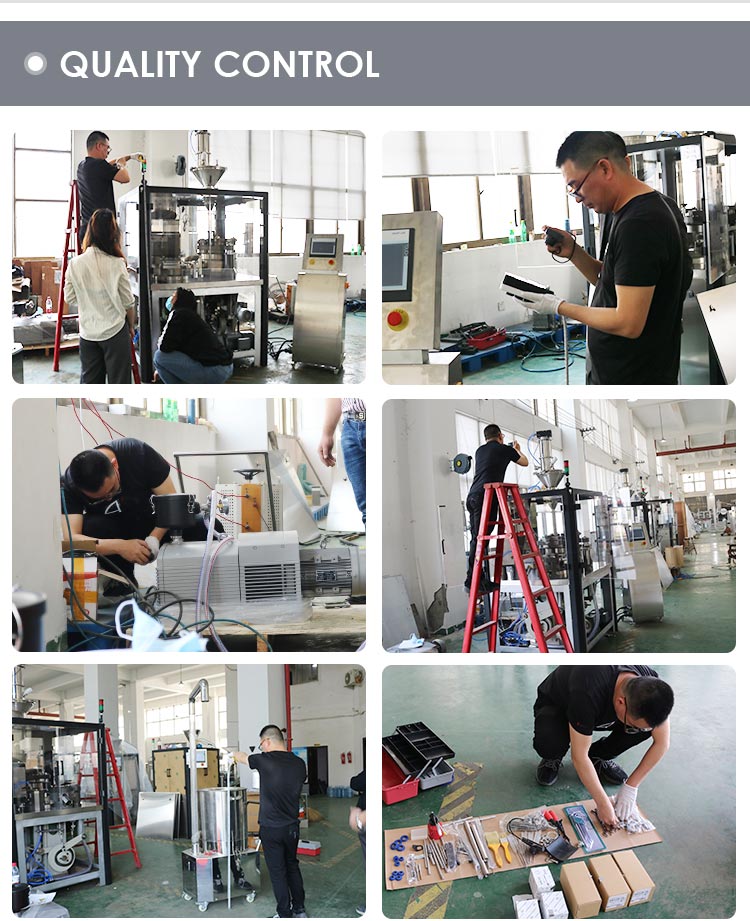

The full-automatic pharmaceutical capsule 2600C NJP capsule filling machine in line with CE GMP standard has high-precision mold zero deviation and concentricity to ensure that the capsule is free of burrs. This product adopts double sealing device, so it is closed at capsule outlet, capsule suction, locking and waste discharge stations. The 2600C NJP full-automatic high-speed capsule filling machine suitable for 7-day and 24-hour continuous production has the advantages of low energy consumption, stable operation, convenient cleaning and high production efficiency. Its measuring plate, upper and lower mold holes and filling rod are treated by non-polar electronic polishing, which can well solve the phenomena of mold adhesion, viscosity and moisture absorption of materials, and greatly improve the fluidity of materials.

CE GMP high-speed automatic capsule filling machine 2600C with on-line pneumatic mold cleaning system can ensure that the upper and lower molds are very clean and free of dust pollution, so as to improve the sowing efficiency. This machine can automatically realize capsule separation, reject unqualified capsule materials, sow, fill, lock and output finished products. It is the preferred mechanical product for Chinese and Western pharmaceutical factories, health products and other manufacturers.