Introduction

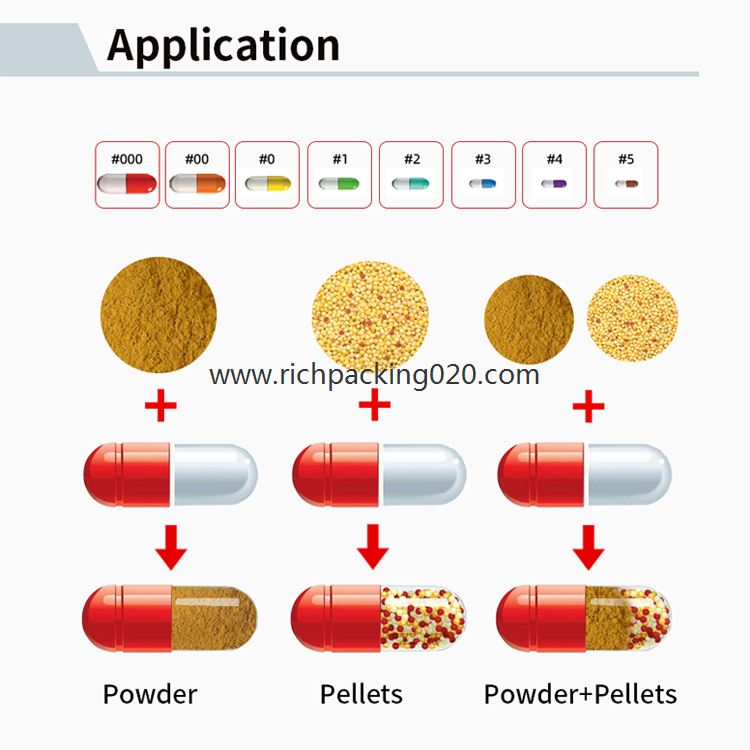

This machine is an upgraded version of semi-automatic capsule filling machine. It is mainly used for filling powdery and granular materials to empty capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#). It can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output. It has the advantages of accurate loading, stable operation and no dust. It meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .

Main Features

1、The new type of pneumatic feeding is adopted, which has better effect on the filling of materials with poor fluidity.

2、The filling rod holder of the capsule filling machine adopts a pull-out slot design, and it is easy and convenient to replace various types of filling rods.

3、Reasonable design,modular structure, easy operation and lower failure rate.

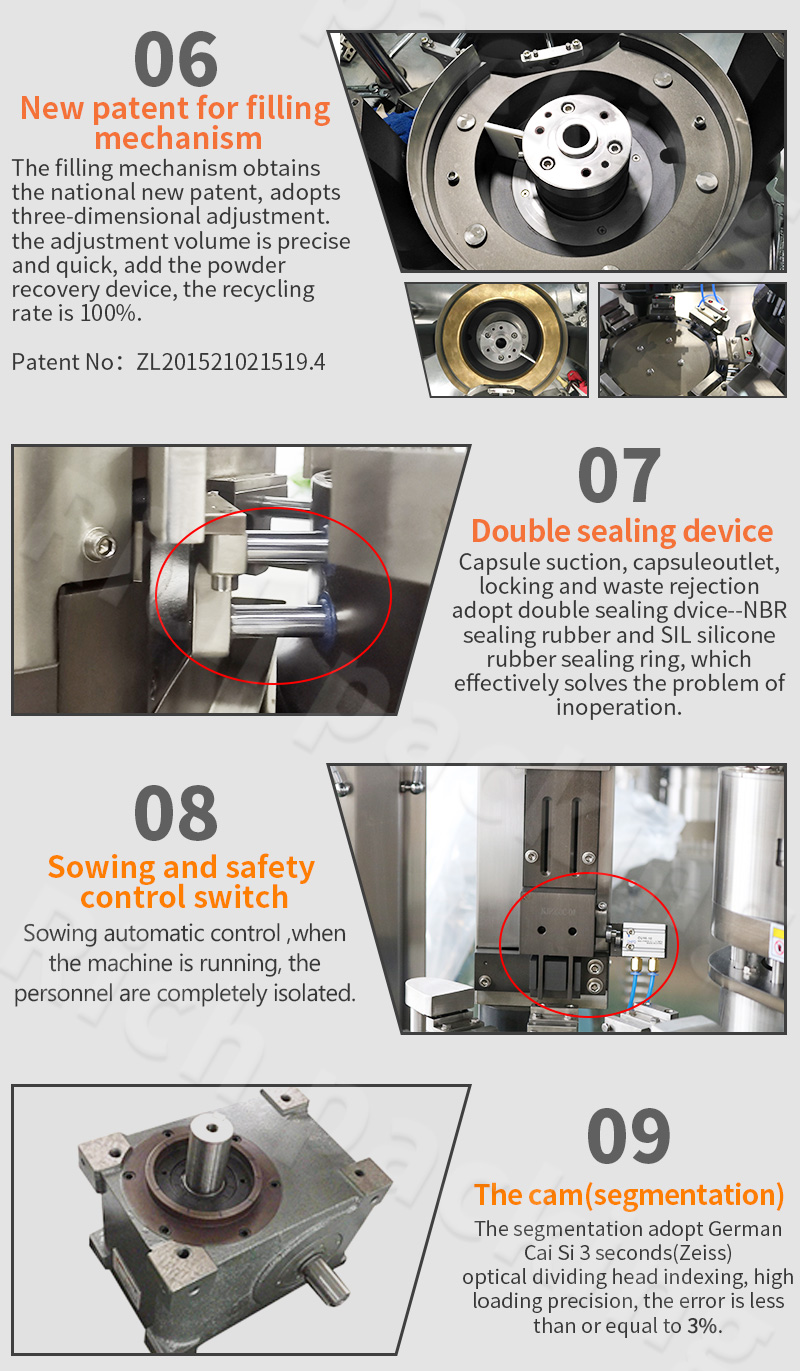

4、Safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

5、With high precision, the error is less than 3%.

6、Rotary design to obtain a utility model patent, good sealing, no dust overflow pollution; .Modular structure, cleaning, replacement of mold, 15 minutes.

7、The filling mechanism has obtained the new national patent, adding the powder recovery device, and the recovery rate is 100%.

8、Equipped with on-line air pressure die cleaning system, the upper and lower dies are clean and without dust, improve the sowing effect.

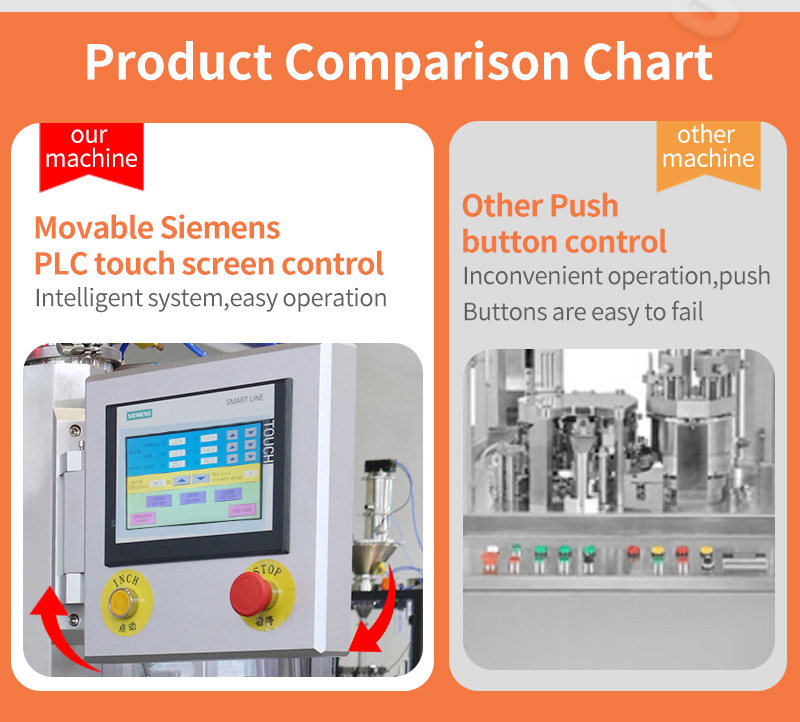

9、Precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage.

10、Automatic rejection device, improve the charging efficiency.

11、The control appliance adopts the world famous brand, modularized setup, convenient inspection and maintenance, SIEMENS human machine interface, real-time counting, and can print the equipment according to customer needs, print production date, batch number, code, etc.

12、All the parts of the contact drug are made of stainless steel 316, and the waste device adopts seven lines of aero aluminum.

13、The equipment is small in volume, low in energy consumption, convenient in cleaning and stable in operation. It is suitable for continuous production of 24 hours.

Main Technical Parameters

Production capacity | 12000 pcs/h |

Net weight of machine | 600Kg |

Overall size of machine | 1000×710×1900(mm) |

Power | 380/220V 50Hz |

Total power | 3KW |

No.of segment bores | 2 |

Vacuum | 20m3/h-0.04-0.08Mpa |

Dust collector | 17.6Kpa 180m3/h |

Noise | <75DB(A) |

Making rate | Empty capsule 99.9% Full capsule 99.8% |

Applicable capsule | 000,00,0,1,2,3,4,5# |

Filling error | Western medicine:±3% Chinese medicine:±4% |

Applicable product | Power、granule、pellet、tablet |