ZH-120L Automatic Carton Box Packing Machine For Cosmetic Skincare Bottle Tube Facial Cleanser

Model | RQ-ZH-120L |

Speed | 35-125 carton/min |

Total power | 1.1 KW |

Power supply | 220/380V 50Hz |

Requirements of carton | size range of carton:L(65-150)*W(35-85)*H(12-45)mm |

carton weight:240-360g/m2 | |

Requirements of instructions | size range of instructions:L(78-250)*W(85-170)mm |

range of folding times of instructions:1-4 fold | |

instructions weight:60-70g/ | |

Pressure | pressure intensity:≥0.6MPa |

air consumption:120-160 L/min | |

Overall size of the machine | 2150*1140*1800mm |

Net weight of the machine | 1500kg |

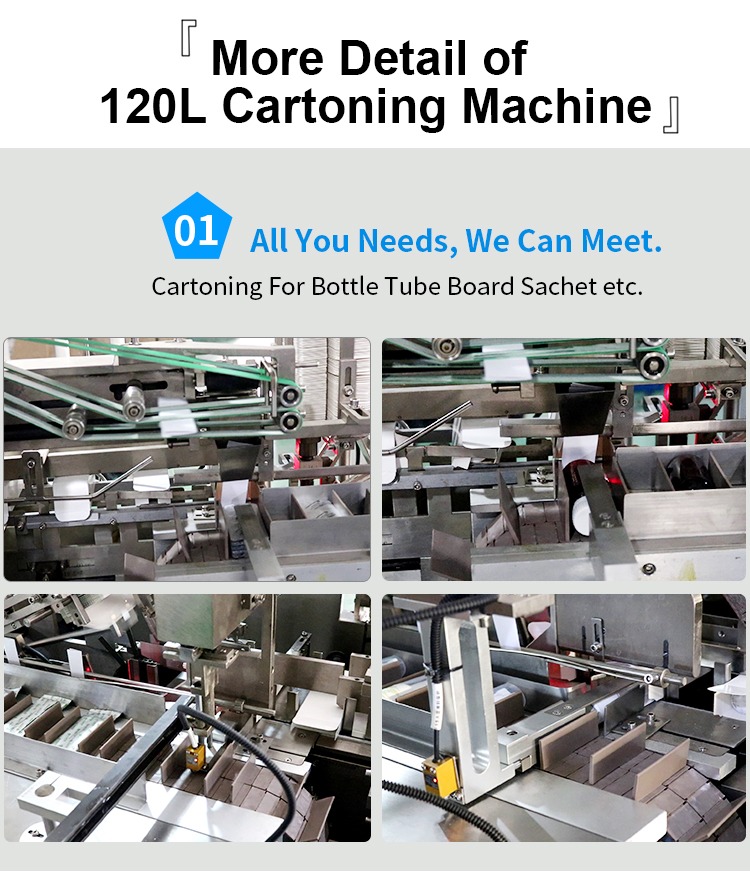

The 120L bottle tube plate bag vertical automatic cartoning machine is made of stainless steel and nickel chromium electroplating materials. It is smooth, harmless, durable and solid. It is a product in line with GMP standards and high cost performance. It is a three-dimensional packaging vertical cartoning machine that can package products of various specifications. The material detection is very accurate, and it can be packaged online, fully automatic and independent.

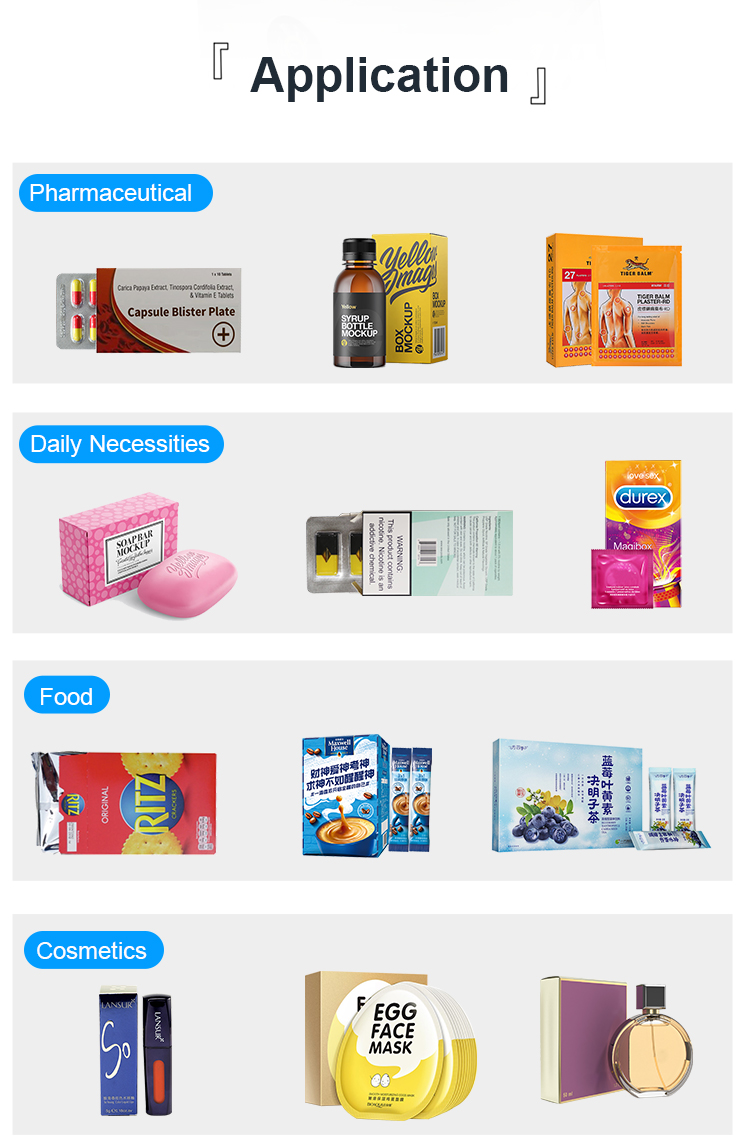

The 120L vertical flat automatic cartoning machine developed by Ruiqi has small volume and simple operation. It is popular in pharmaceutical, food, daily necessities and other industries. The products can be used in packaging facial cleanser, condom, coffee bar, ointment, bagged, biscuit, electronic cigarette, bagged tea and other packaging products and bottled products of different categories in all walks of life. The automatic vertical plate bottle tube vertical bagging and cartoning machine can complete products of different sizes or specifications in one-stop packaging. Therefore, this machine realizes the full-automatic production process and saves a lot of labor consumption and production efficiency of many manufacturers.

Zh120l vertical plate cartoning machine has high precision, stable components, humanized design of modular structure of the machine itself and automatic emergency stop in case of emergency (protective device of the machine). It is precisely because of the intelligent design of the machine that the process of packaging materials (such as material feeding, quantity packaging and testing, feeding into conveyor belt packaging, carton in place and other steps)can ensure that materials do not cause additional waste, And ensure the safety of operation on the operator.