Model | RQ-ZH-12OW |

Speed | 30-125 carton/min |

Total power | 0.750 KW |

Power supply | 220/380V 50Hz |

Requirements of carton | size range of carton:L(70-185)*W(35-90)*H(14-50)mm |

carton weight:250-350g/㎡ | |

Requirements of instructions | size range of instructions:L(78-250)*W(90-170)mm |

range of folding times of instructions:1-4 fold | |

instructions weight:60-70g/㎡ | |

Pressure | pressure intensity:≥0.6MPa |

air consumption:120-160 L/min | |

Overall size of machine | 4300*1100*1550㎜ |

Net weight of machine | about 1600kg |

Our Guangdong

Our Guangdong RQ Company produces this multifunctional cartoning machine 120w model, which can be used to treat various pharmaceutical materials and micro-small medical devices IN 120w, various foods including foods and seasonings and various skin care products 120w such as soft Tube-type hand cream various skin care products for men and women, etc. 120w are packaged. The 120w fast cartoning machine can put the above-mentioned materials into the carton together through various complicated and precise cartoning procedures.

RQ's ultra-high-speed 120w automatic cartoning machine has many advantages.

First of all, our 120w automatic cartoning machine has a very compact structure design. Many professionals from RQ have improved and upgraded the 120w cartoning machine at the early stage of design and manufacture. Each station of the 120w does not take up extra space. As a prerequisite, 120w achieves the effect of maximizing space.

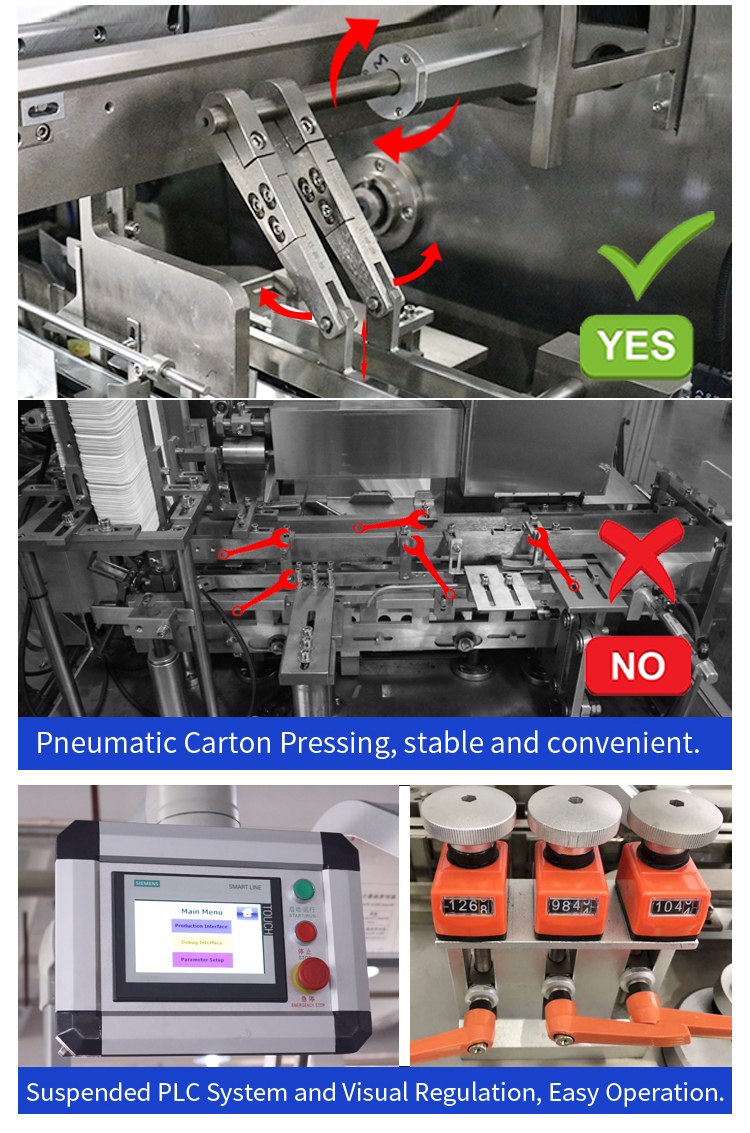

The 120w uses advanced servo motors to complete these ingenious cartoning processes, and uses a scientific cylinder device to carry out a stable and efficient material cartoning process through negative and positive pressure.

Customers can choose whether the 120w is equipped with a date and batch number printing device and whether to add a hot melt glue machine to glue the sticker box according to their own needs.

The international big-name PLC control unit configured with 120w will automatically display the possible fault prompts and troubleshooting displays and the defective rate of finished products in the cartoning workflow.