Introduction

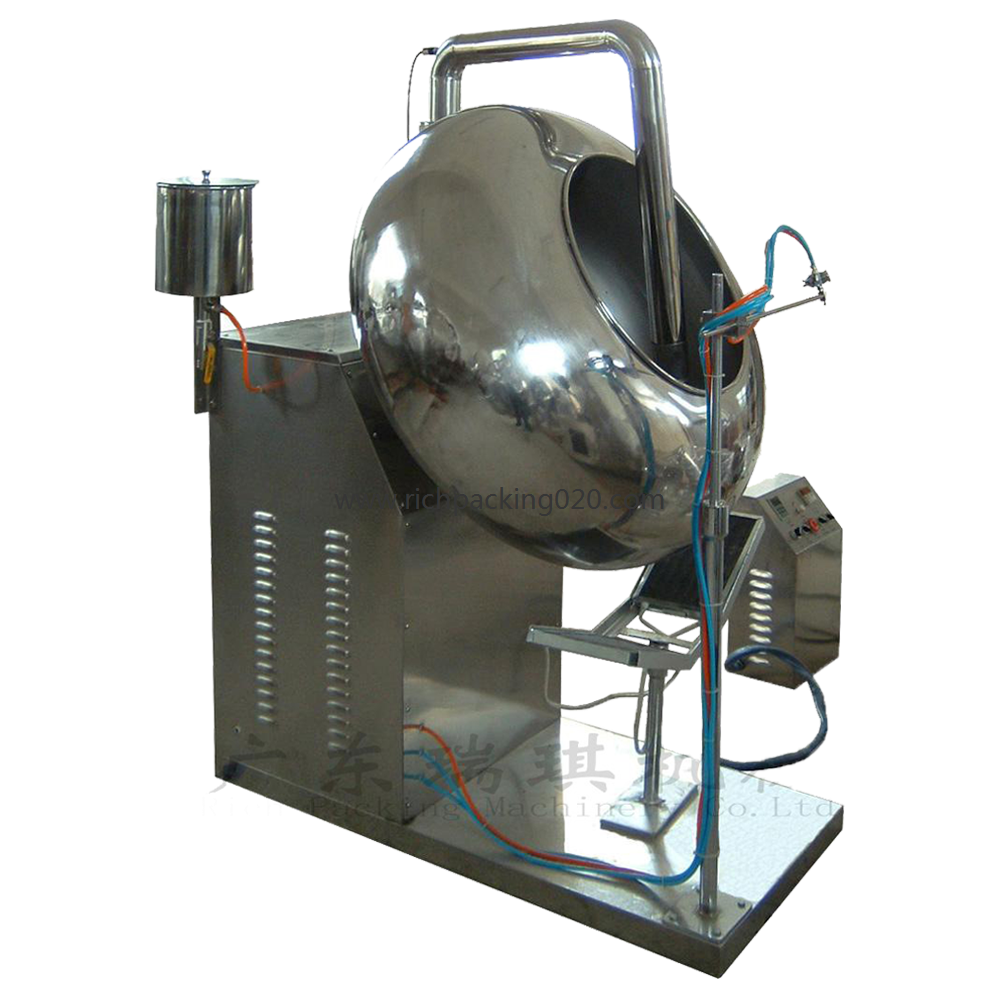

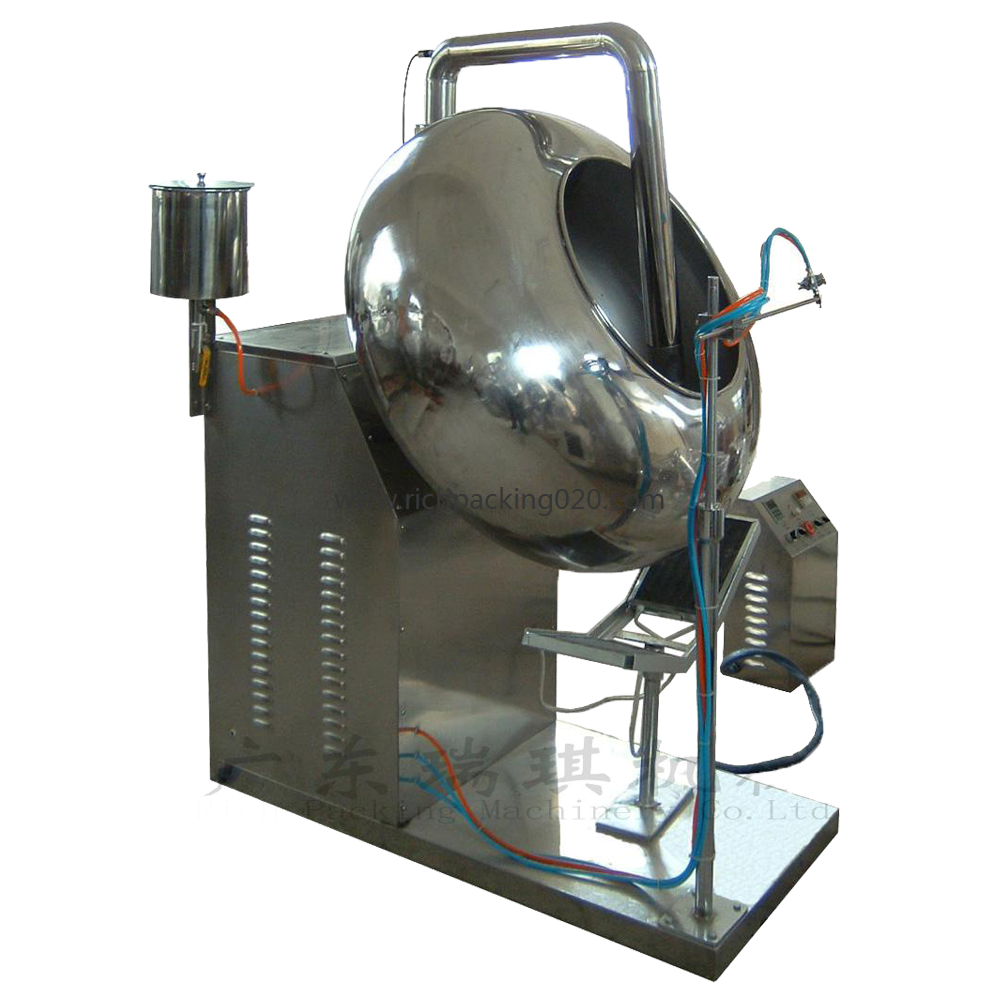

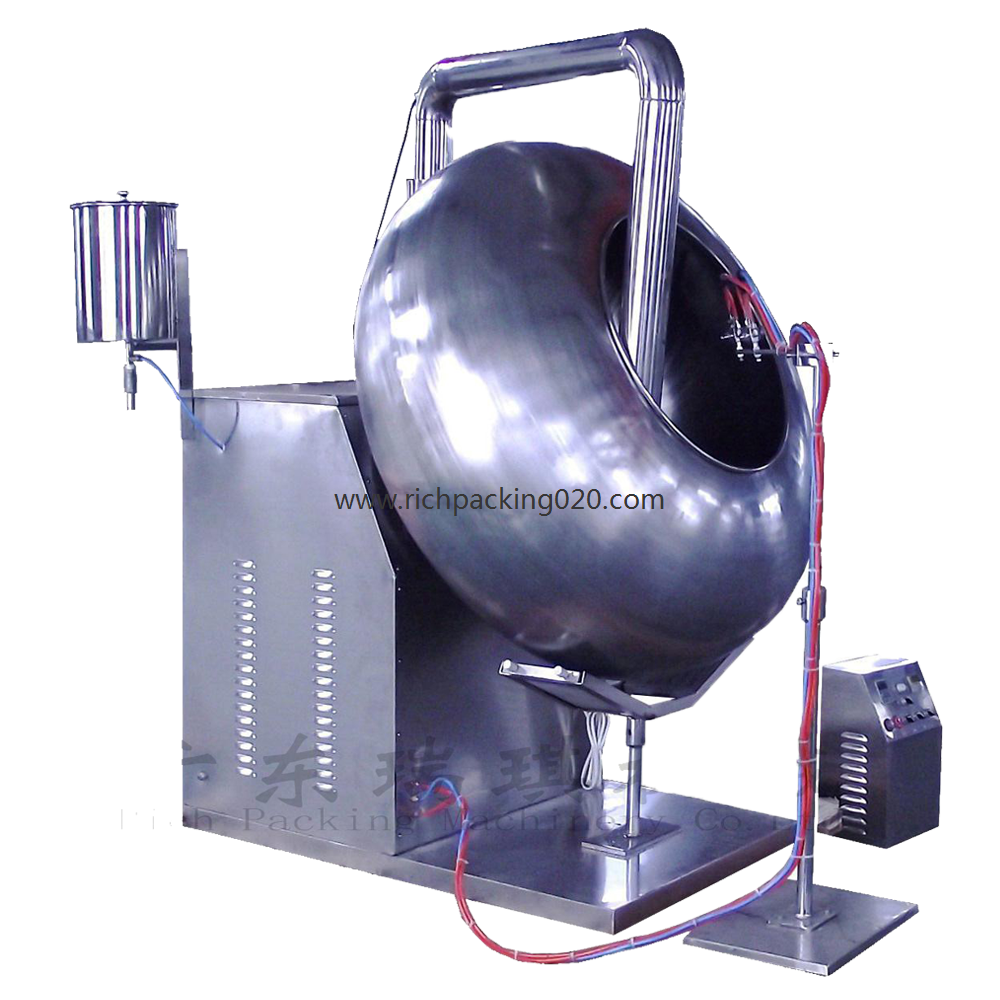

This set is used to carry out sugar coating and film coating to the core of Chinese traditional and Western medicine tablets. It integrates strong power, weak power, hydraulic and pneumatic. It is new type equipment that improved on the basic of original common type sugar coating machine.

It is composed of the mainframe (original sugar coating machine), controllable normal temperature hot air system, automatic liquid supply and air supply spraying system, etc.

Main Features

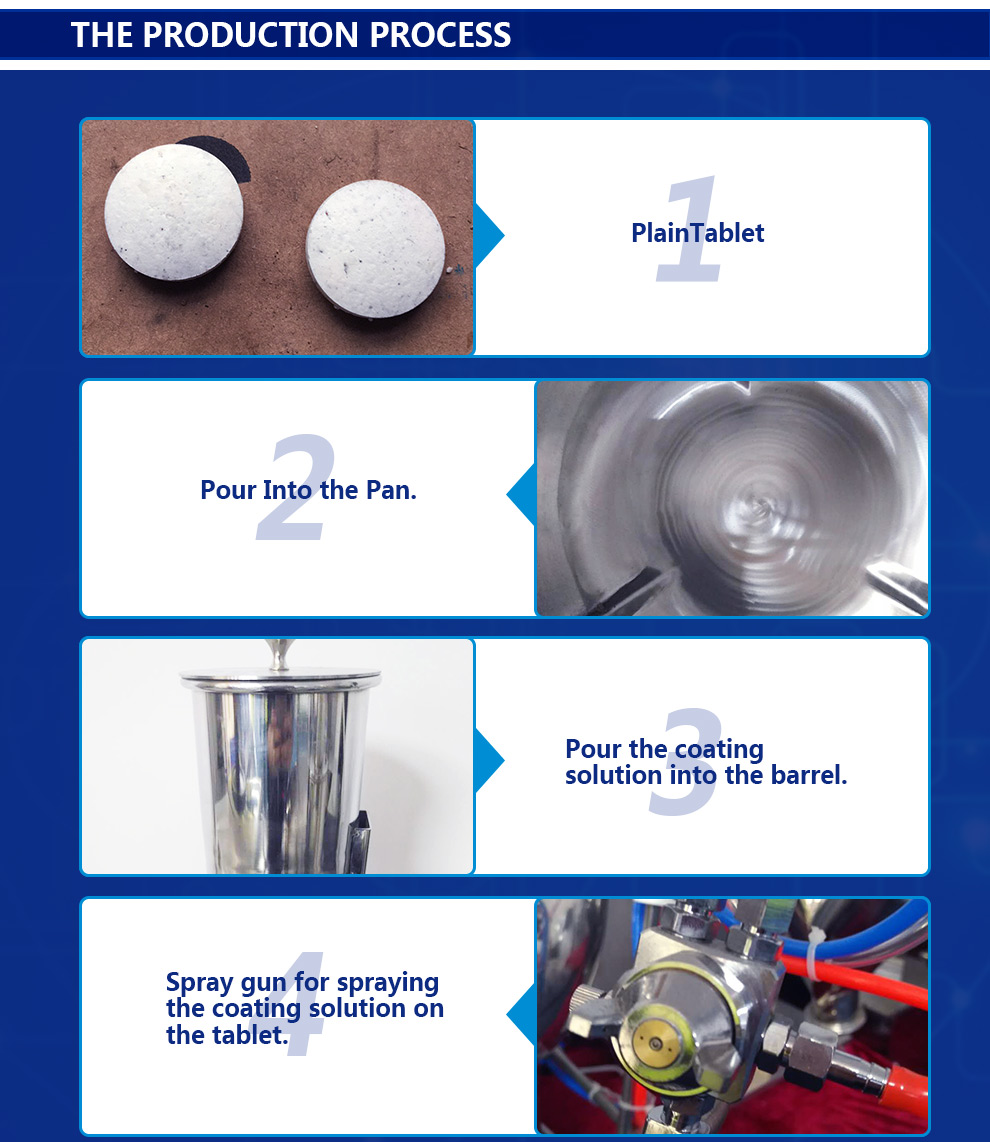

1.The motor adopts frequency converter, using high atomization gun sprays the coating accessories to tablets surface by the method of automatic electrical control.

2.Meanwhile, the tablets will make continuous and complex track movement in the coating pan; let the coating solution cover the tablet core evenly. The controllable normal-temperature hot air system in the pan will dry the tablets at the same time; let the tablets rapidly form a firm, fine, complete and smooth surface film.

3.Automatic liquid supply vehicle is used for heating and insulation the coating solution that requires higher temperature and the temperature is also adjustable.

4.Barrel is lined with heat insulation rock wool, even the heating temperature achieves 80-90℃, but the outer wall of barrel still keeps normal temperature.

5.The liquid supply vehicle is equipped with peristaltic pump and three-way magnetic valve, which can make the two spray gun work at the same time. It is also equipped with pneumatic stirring motor that can continually stir coating solution, and the speed of stirring is adjustable.

6.There is also wheel installed at the bottom of vehicle so that users can move it randomly.

7.This machine has advantages of simplified operation, smooth, fine and bright surface, saving accessories and convenient maintenance. It is the ideal equipment for tablet film coating.

Main Technical Parameters

Model | BYC(A)-600 | BYC(A)-800 | BYC(A)-1000 | BYC(A)-1250 |

Production Capacity | 8-15kg/time | 30~50kg/time | 50~70kg/time | 80~150kg/time |

Inclination of Pan | 15°-45° | 15°-45° | 15°-45° | 15°-45° |

Motor Power | 0.75kw | 1.1kw | 1.5kw | 2.2kw |

Power of Blower Fan | 60w | 200w | 200w | 370w |

Rotary Speed | 0-40r/min | 0-32r/min | 0-32r/min | 0-28r/min |

Electric Thermal Power | 2KW | 3KW | 4KW | 6KW |

Weight | 150KG | 280KG | 300KG | 500KG |

Outline Dim.(mm) | 840×760×1310 | 1000×1000×1550 | 1300×1000×1680 | 1350×1350×1600 |

Automatic liquid supply vehicle | |

Volume of barrel | 30L |

Heating power | 3Kw |

Electrical Source | Single pharse |

Flow | 0.34-870ml/min |

Silicone rubber tube | 24# |

Working pressure | 0.4-0.8Mpa |

Spray gun | According to users’ demand |

Weight | 60Kg |

Outline dim. | 780×620×830mm |