General Description

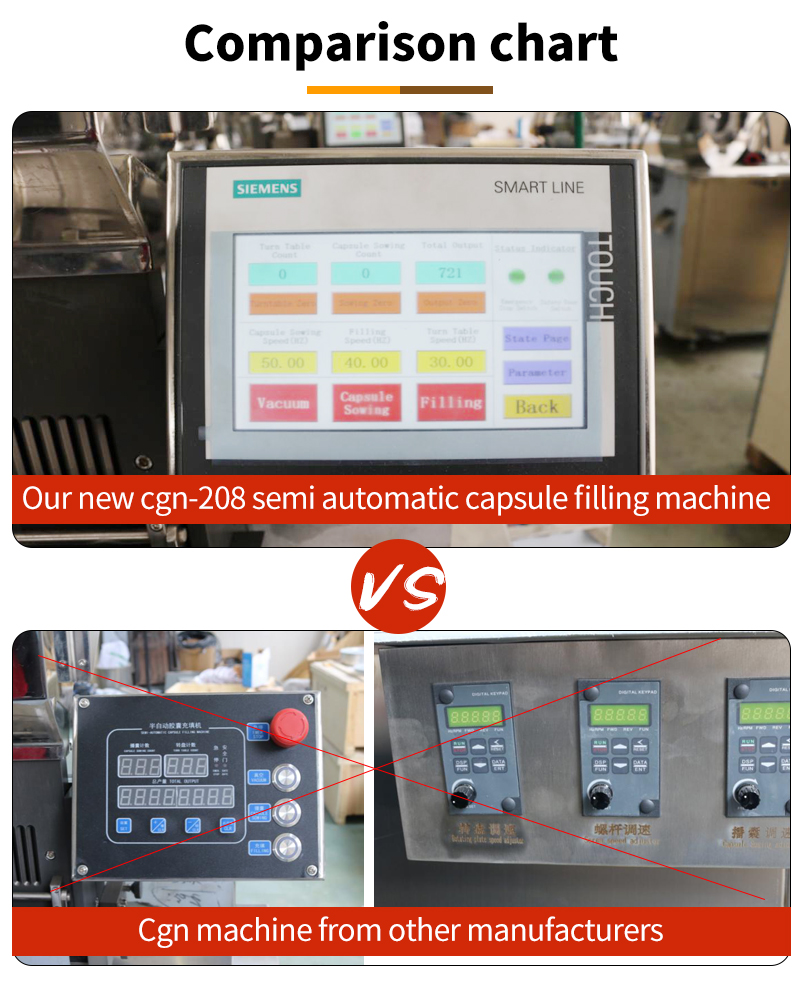

New Model of capsule filling machine change to touch screen operate control,convenient operation, prolongs the service life of the whole body, and more high-end.

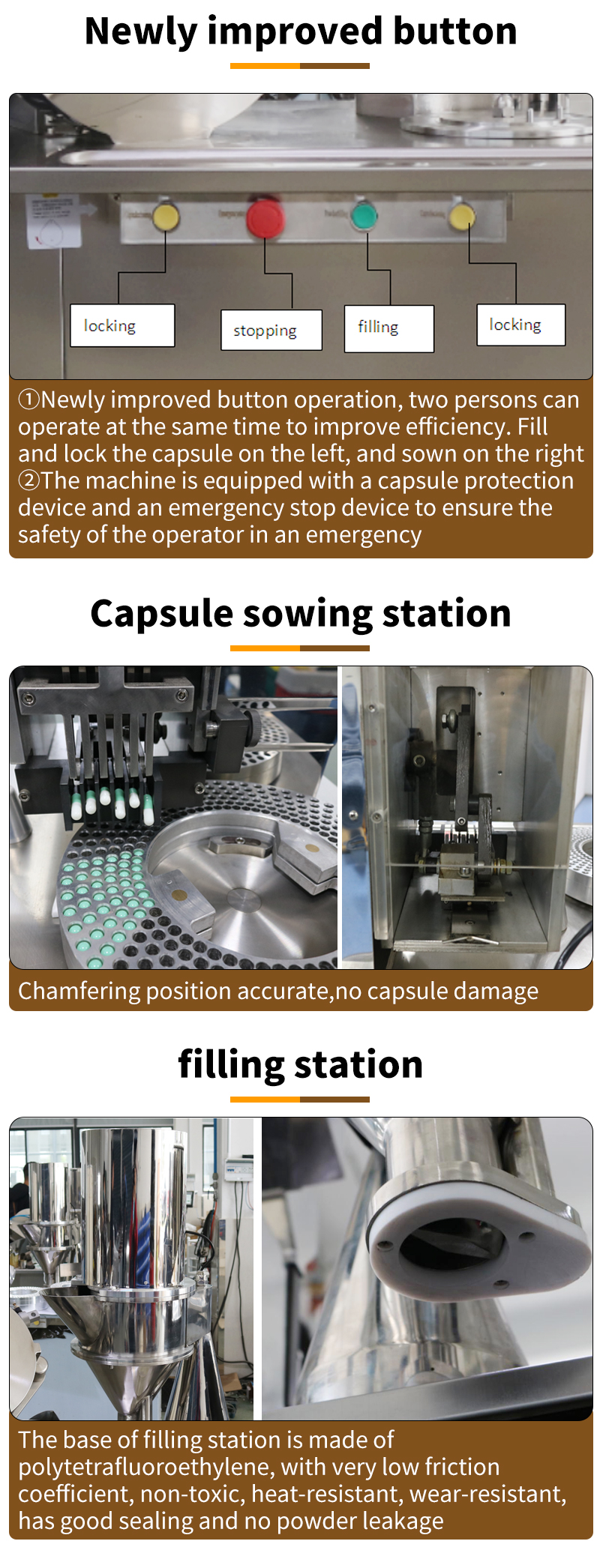

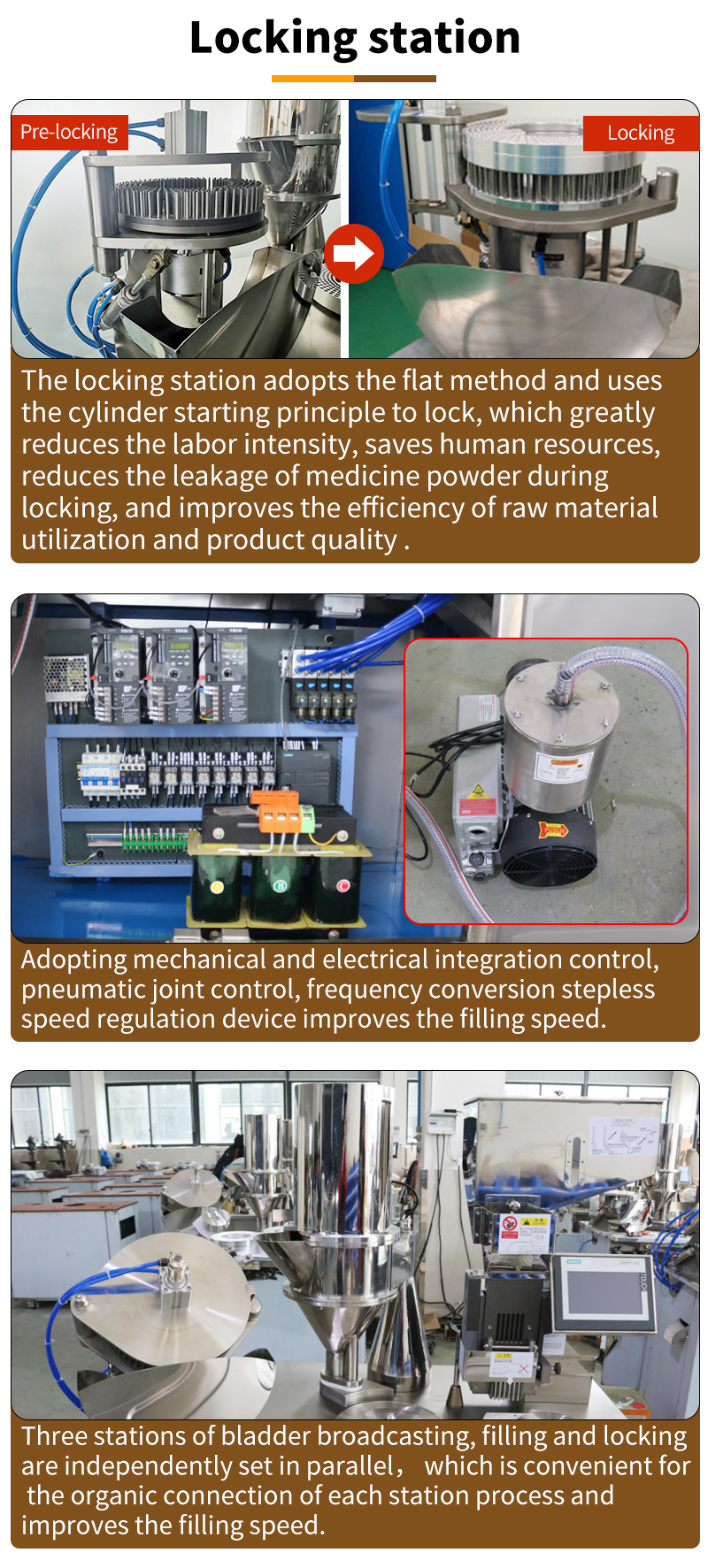

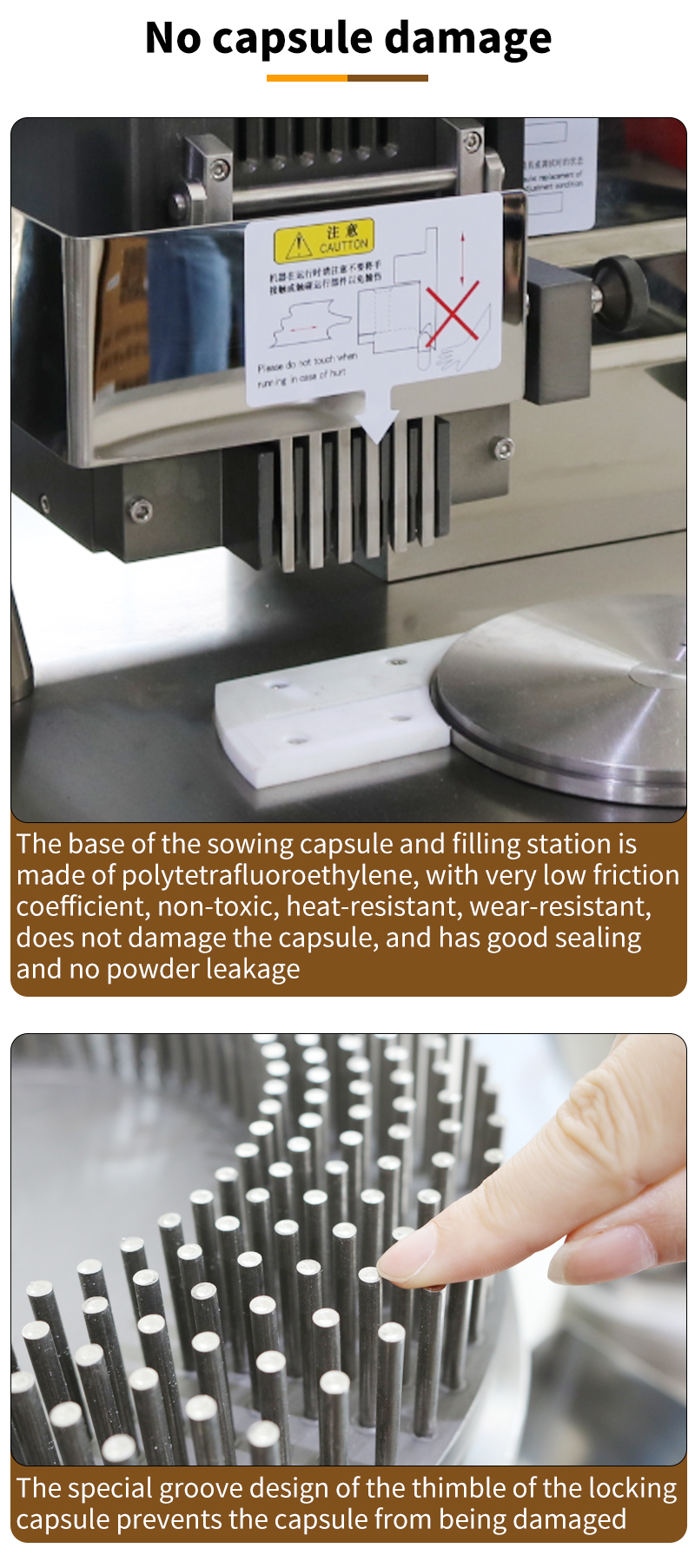

Broadcast capsule part adopts the structure of fully automatic capsule filling machine, so as to enhance the precision reduces friction, lock capsule part adopts flat mode, using the pneumatic principle to achieve theautomation, effectively prevent powder tremor, improve product quality,reduce manpower, easy to use.

The new model of Capsule filling machine is of pharmaceutical packaging machinery, the advantages of novel structure, beautiful shape, the use of mechanical and electrical integration control, pneumatic control, equipped with Siemens programmable control (PLC)

device, frequency conversion stepless speed regulating device, can respectively complete

capsule in place, separation, filling, locking action, on the basis of NTJ-C also greatly improved, thus to replace the manual filling, reduce labor intensity, improve the production efficiency, accurate filling dose on the basis of upgrade again, more in line with the requirements of the pharmaceutical and health.

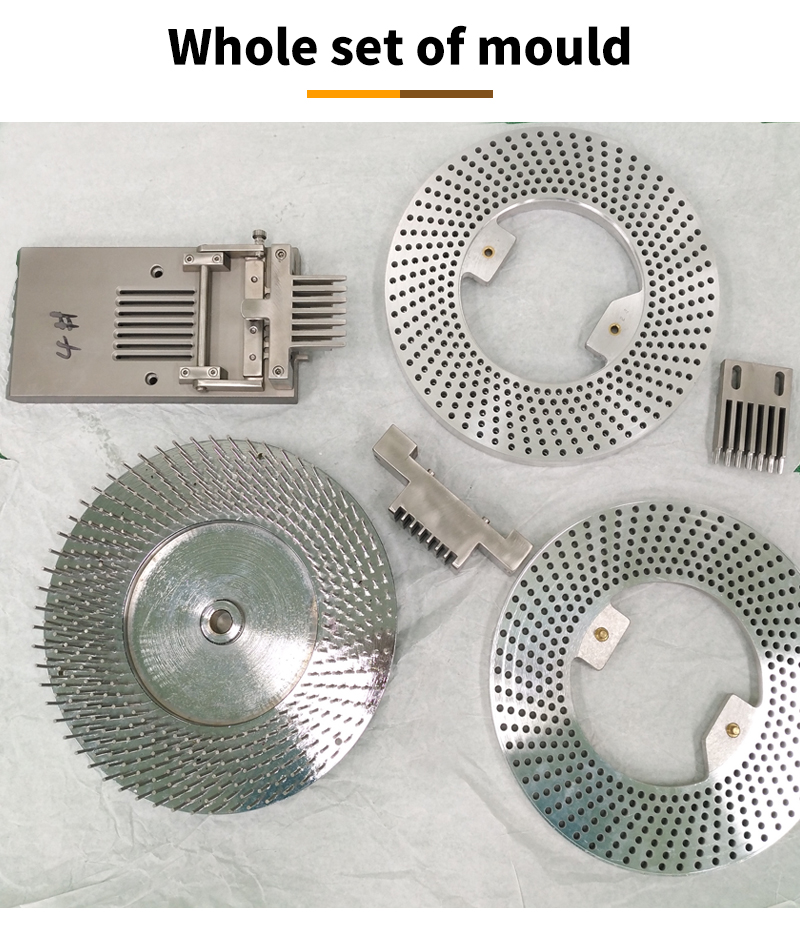

This machine is composed of several parts: send cystic U-turn separation mechanism, filling mechanism, locking mechanism, variable frequency speed regulating mechanism and pneumatic control and electric control system, protection device and other components, vacuum pump and pump accessories. Domestic or imported capsule all can be applied, product qualification rate reached 98%.

Specification

1 Productivity 15000-28000 pcs/h(ONE SET MOULD)

2 Applicable capsules: 000#, 00#, 0#, 1#, 2#, 3# ,4#, 5# machine-made standard capsules

3 Filled medicine type: Not adhesive or wet powders and small granules

4 Total power: 2.12Kw

5 Air pressure: 0.03m3/min, 0.7MPa

6 Vacuum pump: evacuating rate: 40m3/h

7 External dimensions(mm): 1300X800X1750 (LXWXH)

8 Weight: 400KG