Introduction

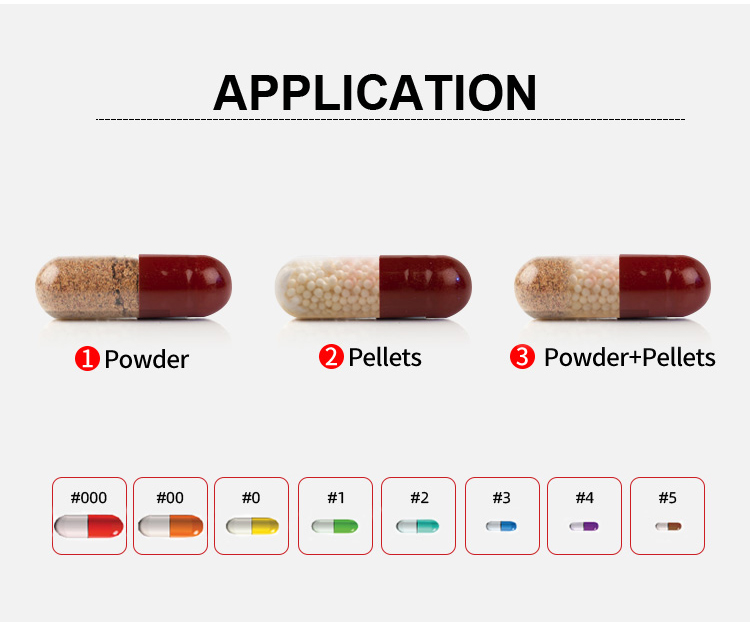

The model is the third generation of innovative products. It has 6 technological innovations and 2 invention patents. It can fill powder, granules and other materials into hollow capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#). It can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output. It has the advantages of accurate loading, stable operation and no dust. It meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .

Main Features

1、Pneumatic cutting. Adopting new type of pneumatic feeding, it is more effective for filling materials with poor fluidity.

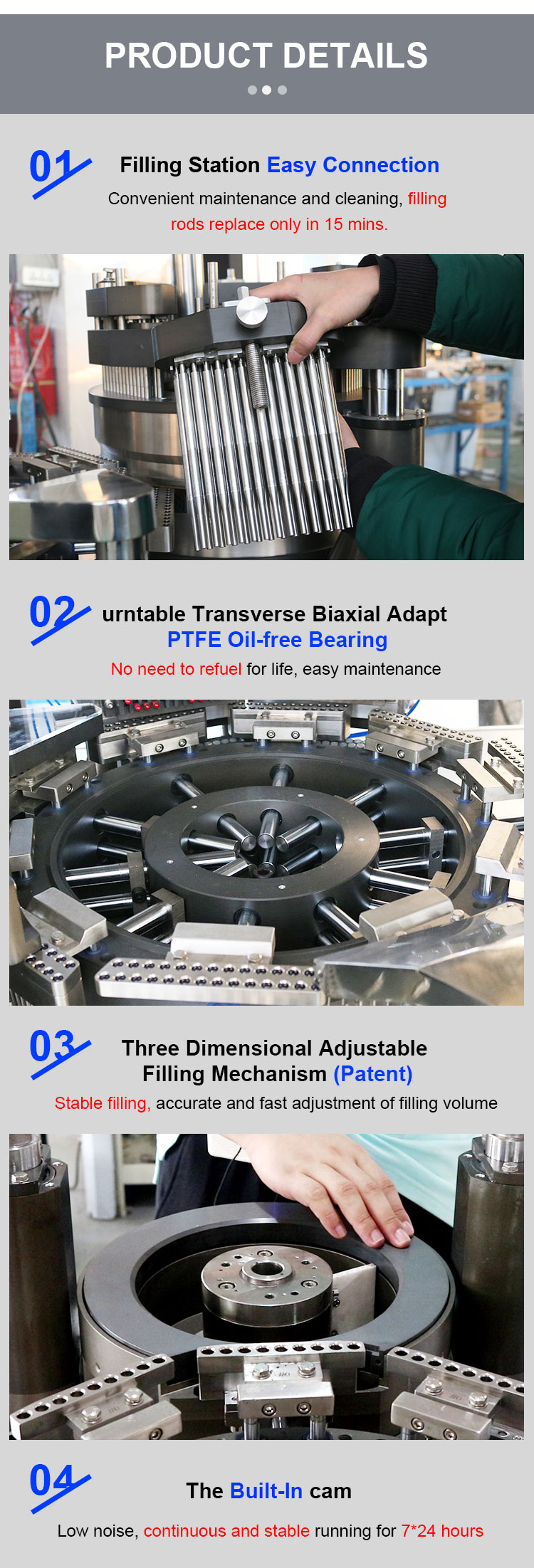

2、The equipment is easy to maintain. The built-in cam of the capsule filling machine can be lubricated with a single injection of grease to ensure continuous lubrication, which ensures the transmission of the transmission mechanism without dripping oil and meets GMP requirements.

3、The inner groove cam of this series of capsule filling machine is formed by CNC machining center at one time, without splitting and splicing, seamless, stable and better, and the transmission mechanism has no noise during high-speed production of the equipment.

4、Capsule filling machine's filling rod holder adopts a pull-out slot design, making it easy to replace various types of filling rods

5、Reasonable design,modular structure, easy operation and lower failure rate.

6、Safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

7、Segmentation adapt German Cai Si for 3 seconds (Zeiss) optical dividing head indexing, indexing shaft completed a one-time processing, loading and high precision, the error is less than or equal to 3%.

8、Rotary design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow pollution; Transverse biaxial adapt PTFE oil-less bearing, no need refueling; modular structure, equipped with jog operation, convenient maintenance and cleaning, replacement of mold only 15 minutes.

9、The use of the high precision cam indexing box has completely changed the past 83DS failure frequency, even the phenomenon of the fracture of the force shaft and the output shaft. It is the only enterprise that adopts 100DS and 100DS indexing box in our country at present. The continuous operation of the equipment has been guaranteed.

10、The filling mechanism obtains the national new patent, adopts the three-dimensional adjustment, makes the metering plate evenly force, the adjustment volume is precise and quick, and the powder recovery device is added, the recycling rate is 100%, which reduces the waste and improves the economic benefit.

11、Capsule suction, capsule outlet, locking and waste rejection adapt double sealing device, one is imported NBR sealing rubber which prevents the loss of lubricating oil. The other seals use the imported SIL silicone rubber sealing ring to block the powder into the bearing, which effectively solves the problem of the card machine that the powder enters the bearing.

12、The filling rod, the upper and lower die holes, the measuring disk adapt non polar electronic polishing treatment, enhance the material fluidity, which has solved the problems of sticky of material, stick with mold and easy to absorb moisture. (According to the material properties and the special requirements of customers, we can provide the Teflon coating processing service)

13、According to the modular and integrated design idea, three tail fixed brackets are added to improve the bearing capacity of the bracket, so that the upper part and the bottom of the equipment form an organic unified structure, and the stability is greatly enhanced.

14、The mechanism of capsule won the national utility models patent, using cylinder push pull over discharge, avoid dust.

15、Equipped with on-line air pressure die cleaning system, the upper and lower dies are clean and without dust, improve the sowing effect.

16、Precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage.

17、Automatic rejection device, improve the charging efficiency.

18、The control appliance adopts the world famous brand, modularized setup, convenient inspection and maintenance, SIEMENS human machine interface, real-time counting, and can print the equipment according to customer needs, print production date, batch number, code, etc.

19、The separation device has been innovated to separate the powder from the waste capsule and avoid the pollution of the reclaimed powder. (Optional)

20、All the parts of the contact drug are made of stainless steel 316, and the waste device adopts seven lines of aero aluminum.

21、The equipment is high production, low in energy consumption, convenient in cleaning and stable in operation. It is suitable for continuous production of 24 hours.

Main Technical Parameters

Production capacity | 228000 pcs/h |

Net weight of machine | 2200Kg |

Overall size of machine | 1500×1200×2200mm |

Power | 380/220V 50Hz |

Total power | 10.5KW |

No.of segment bores | 27 |

Vacuum | 120m3/h-0.04-0.08Mpa |

Dust collector | 24.5Kpa 210m3/h |

Noise | <75DB(A) |

Making rate | Empty capsule 99.9% Full capsule 99.8% |

Applicable capsule | 000,00,0,1,2,3,4,5# |

Filling error | Western medicine:±3% Chinese medicine:±4% |

Applicable product | Power、granule、pellet、tablet |