HOT PRODUCTS

Details

Home

> NEWS

> Industry News > Details

Home

> NEWS

> Industry News > Details

Fully Automatic Capsule Filling Machine Brings Convenience To The Filling And Production Of Capsules

Fully Automatic Capsule Filling Machine Brings Convenience To The Filling And Production Of Capsules

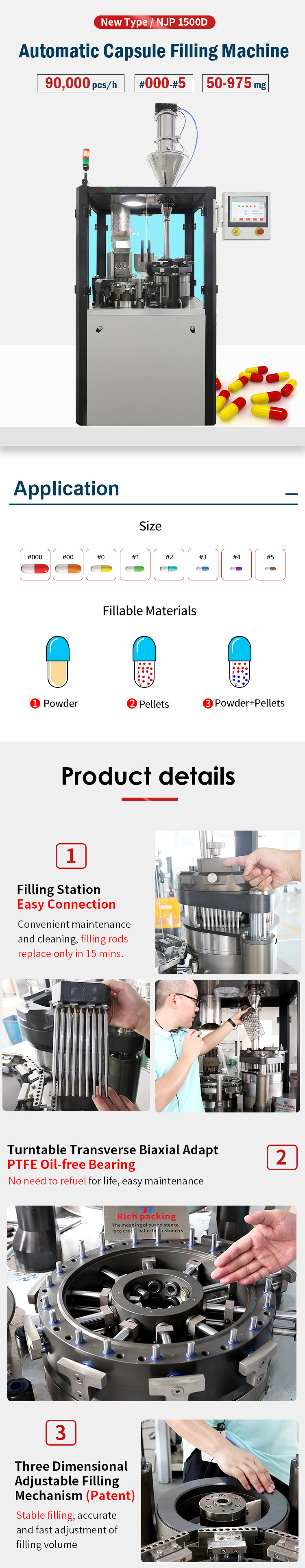

The automatic capsule filling machine is a device for filling powder, granules or small tablets into hollow capsules. The product adopts plug-type filling, intermittent operation, frequency conversion speed control, and is suitable for powder or pellet-shaped capsule drugs. Automatically complete sac sowing, splitting, filling, (waste sac removal) locking sacs, finished product output, etc. It is an advanced filling machine developed by our factory by absorbing the advantages of similar products at home and abroad combined with the domestic actual situation. The production process is fully GMP compliant. specification. The emergence of automatic capsule filling machine has brought great convenience to the filling and production of capsules. It not only improves the efficiency of capsule filling, but also effectively solves some problems existing in ordinary capsule filling machines. As the pharmaceutical market passes through the cold winter, the capsule market will also usher in a broad market space. At the same time, as the country's requirements for pharmaceutical quality increase day by day, the quality of capsules has attracted more and more attention.

Main features of automatic capsule filling machine:

1. The internal design of the die turntable is improved, and the original linear bearings are used to ensure the accuracy and service life of the equipment.

2. It adopts a cam under-mounted design and adds a pressure atomizing oil pump to keep the cam groove lubricated, reduce wear and extend the service life of parts.

3. The use of enlarged cam indexing box has become one of the few domestic enterprises that use the indexing box as a supporting tool. Although it increases the cost, it greatly improves the stability and service life of the machine.

4. Computer control, stepless frequency conversion speed regulation, digital display to achieve convenient operation, eye-catching and intuitive.

5. Based on the lower plane of the metering plate, the three-dimensional adjustment mechanism has a uniform gap, which ensures the difference in loading and accurate measurement, which is controlled within ±3.5%.

6. The capsule control switch is added (control outside the body, safer and more convenient).

7. The inching control system is added to facilitate the humanized operation in production and cleaning.