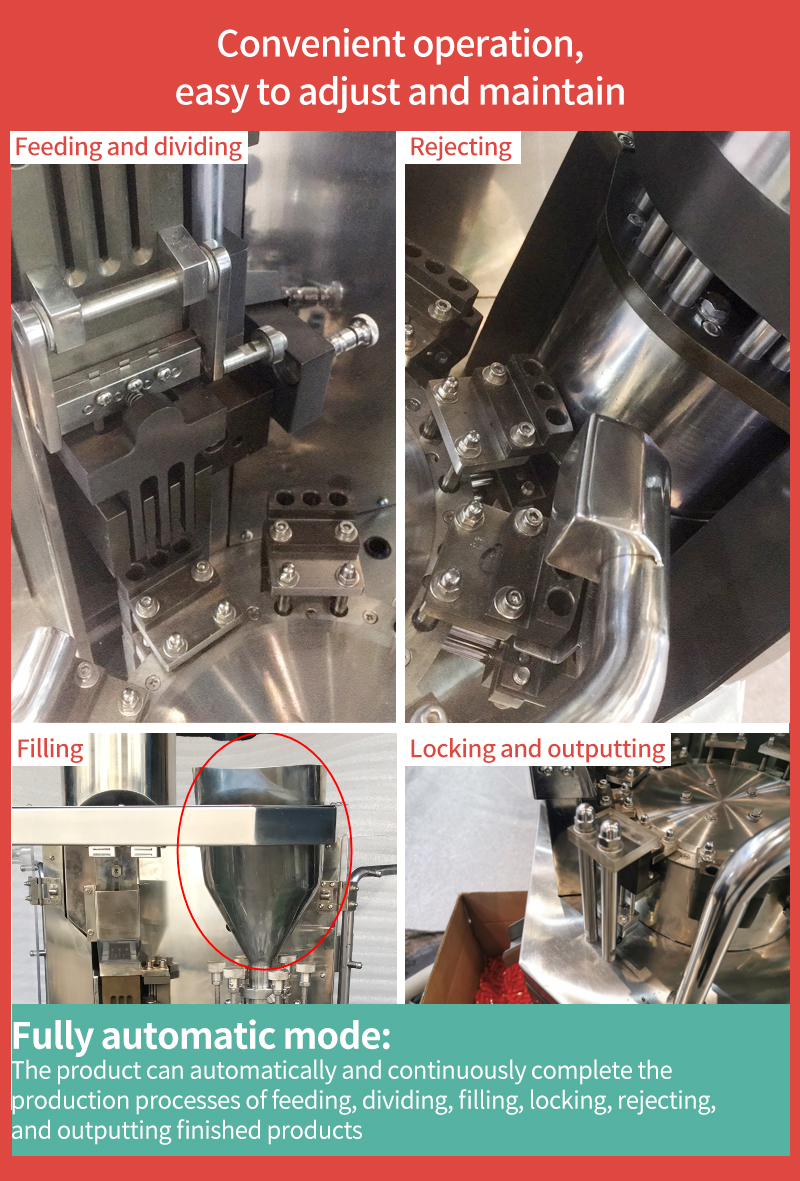

NJPS200/400 is a small, convenient and fully automatic capsule filling machine developed by RICHPACKING for laboratory use. It has 6 major technological innovations and 2 invention patents. It can fill powder, granules and other materials into hollow capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#). The product can automatically and continuously complete the production processes of feeding, dividing, filling, locking, rejecting, and outputting finished products. It has the advantages of accurate loading, stable operation, dust-free, small footprint, low noise, convenient and efficient movement, etc. It meets the requirements of GMP and JB20025-2004 "Automatic Drug Capsule Filling Machine" standard, and it is an ideal equipment for experimental type

Model | NJPS-200 | NJPS-400 |

output | 200/minute | 400/minute |

weight | 300kg | 300kg |

volume | 700*570*1650 | 700*570*1650 |

power | 380/220V 50Hz | |

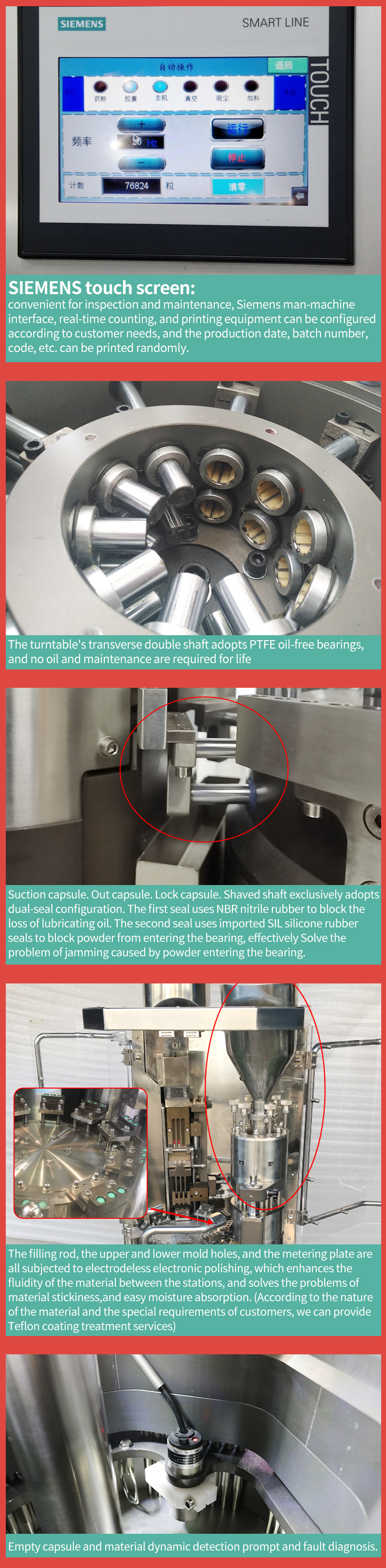

Total power | 3.0KW | |

Number of holes | 2 | 3 |

vacuum | 10m3/h-0.04-0.08Mpa | |

noise | <75DB(A) | |

Making rate | Empty capsule99.9% full capsule99.8% | |

Applicable capsule | 000,00,0,1,2,3,4,5# Safe capsule A-E | |

Filling error | Western medicine±3% chinese medicine±4% | |

Suitable material | Power、granule、pellet、tablet | |

1、Reasonable design,modular structure, easy operation and lower failure rate.

2、Built-in vacuum pump, small size (700*570*1650mm), energy saving and environmental protection, no vibration, low noise.

3、empty capsule and material dynamic detection prompt and fault diagnosis.

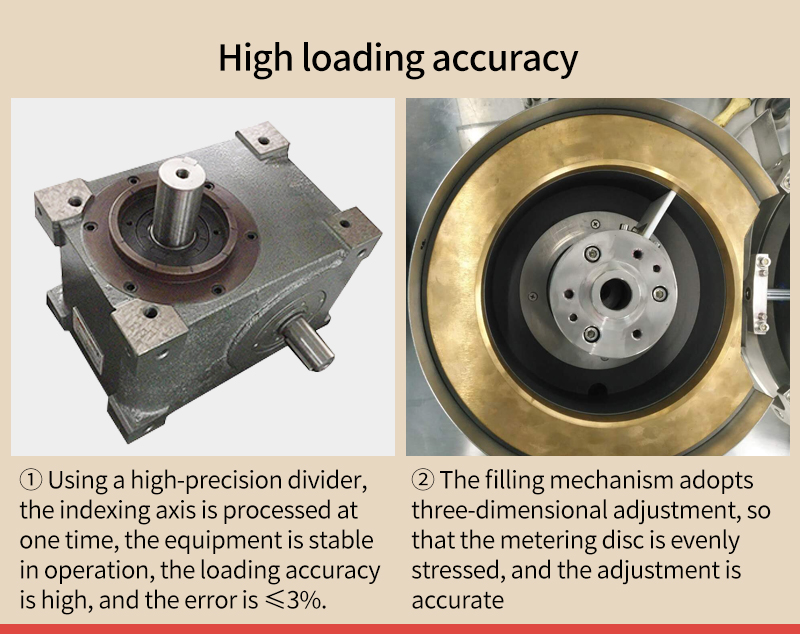

4、Using a high-precision divider, the indexing axis is processed at one time, the equipment is stable in operation, the loading accuracy is high, and the error is ≤3%.

5、99% chance of empty capsules

6、The turntable adopts a sealed design and uses SIL imported rubber and silica gel seals to effectively prevent powder from entering the turntable, with good sealing performance and no dust spillage pollution; the turntable's transverse double shaft adopts PTFE oil-free bearings, and no oil and maintenance are required for life; structure Modular, equipped with inching operation, easy to disassemble and wash, and mold replacement can be completed within 15 minutes.

7、The filling mechanism adopts three-dimensional adjustment, so that the metering disc is evenly stressed, and the adjustment is accurate and fast.

8、Suction capsule. Out capsule. Lock capsule. Shaved shaft exclusively adopts dual-seal configuration. The first seal uses NBR nitrile rubber to block the loss of lubricating oil. The second seal uses imported SIL silicone rubber seals to block powder from entering the bearing, effectively Solve the problem of jamming caused by powder entering the bearing.

9、The filling rod, the upper and lower mold holes, and the metering plate are all subjected to electrodeless electronic polishing, which enhances the fluidity of the material between the stations, and solves the problems of material stickiness,and easy moisture absorption. (According to the nature of the material and the special requirements of customers, we can provide Teflon coating treatment services)

10、The concentricity of the mold is accurate, and there is zero deviation to ensure that the capsule does not rub the edges or damage.

11、Equipped with an online air-compression mold cleaning system, the upper and lower molds are clean and dust-free, which improves the effect of sacking.

12、Automatic waste rejection device improves installation efficiency.

13、The control electric appliance adopts world famous brand, modular setting, convenient for inspection and maintenance, Siemens man-machine interface, real-time counting, and printing equipment can be configured according to customer needs, and the production date, batch number, code, etc. can be printed randomly.

14、All parts contacting the medicine are made of stainless steel 316

15、The equipment is small in size, low in energy consumption, easy to clean, stable in operation, suitable for long-term continuous experiments.