HOT PRODUCTS

Details

Home

> SOLUTION

> Solution of Packing Line > Details

Home

> SOLUTION

> Solution of Packing Line > Details

Tablet&Capsule Cartoning Packing Line

Tablet&Capsule Cartoning Packing Line

This line is suitable for packing the tablet and capsule into the carton, the following machines that composite the whole line. However, it is only for reference. It can be changed according the customer’s products.

The process: Tablet&Capsule Blister Packing Machine→Automatic Cartoning Machine→Transparent Packing Machine→Film Strapping Machine

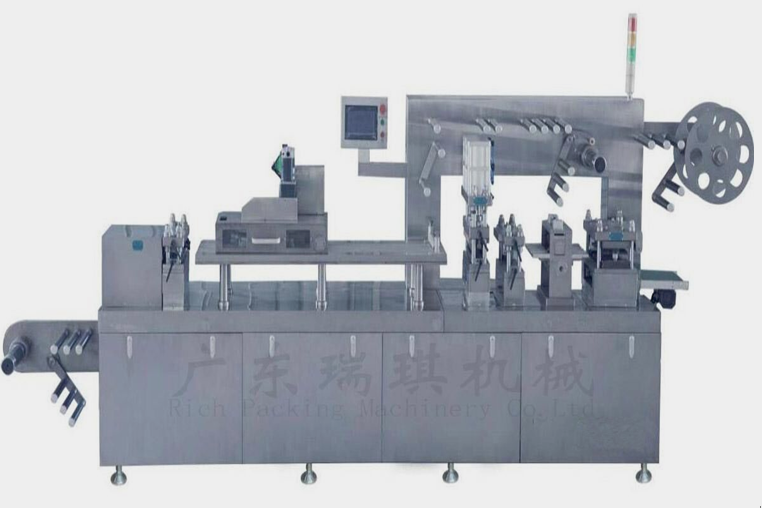

DPK-260H1 Plate Blister Packing Machine

Introduction

This machine is suitable for blister packing tablet, capsule, pill, injection and other medicine, food, electronic component in pharmaceutical, foodstuff, medical equipment, cosmetics, health products and handicrafts and so on.

Main Features

1. Adapt PLC touch screen control, frequency converter, servo motor. The traction length can be randomly adjusted within the range of technical parameters, avoid errors caused by manual adjusted. Reduce the labor intensity and material waste.

2. The heating temperature control and detection, large heating area, the mold is heating evenly.

3. Overload protection device, PVC and PTP material level detecting and alarming.

4. The feeder adapt vibrating ways, smooth and uniform. Ensure product completely. The detection of silo material level and blanking control, reduce friction among materials, ensure the complete of material.

5. The whole machine adapts quick-loading design, which is suitable for various kinds of product. And it is easy to change the mold.

6. Contact type heating, positive pressure forming, sealing cushion.

7. Use special processing and assemble process, ensure the aluminum foil transporting balance, graphic on the version.

8. PVC bearing parts adapt large diameter PVC.

9. With scrap automatic winding mechanism, scrap collecting uniformly, the finished product orderly be sent out. There is output delivery mechanism, which can connect the following equipment for production.

10. It not only can produce PVC-ALU, but also can produce ALU-ALU.

11. The whole machine use split connector design, easy to transport.

Main Technical Parameters

Model | DPK-260H1 |

Cutting frequency | PVC-ALU:25~60pcs/min,ALU-ALU:20~30pcs/min |

Throughput | PVC-ALU:600~14000pcs/min,ALU-ALU:4800~7200pcs/min |

Max.forming depth | PVC-ALU:22mm,ALU-ALU:18mm |

Range of Stroke | 30~120mm |

PVC | 0.25~0.5*260mm |

Dialysis paper | 5~100g*260mm |

PTP Aluminum foil | 0.02~0.035*260mm |

Cooling system | Tap water or recycled water |

Power | 8.5kW |

Power Supply | 380V/50Hz |

Dimensions | 4460*760*1620mm |

Weight | 1850kg |

RP-ZH-120A Automatic Vertical Cartoning Machine

Introduction

This equipment is new model developing base on integrated domestic and foreign vanguard technology .It is high technology product incorporates pneumatic-photo-electronic-mechanic which improve by a large on performance of equipment and working efficiency, realize encasing fast, keep running steady and reliable when fast running.

This machine is suitable for automatic feeding product of multi-variety multi-specifications into carton. Adjust automatic feeding structure conveniently, setup quantity of blisters on touch screen randomly. On line product feeding and detecting, leaflet fold (1-4folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet push into carton, printing batch number, sealing carton with tuck-in or hot melt glue device. Automatically reject lacking of leaflet or product and finished product out.

Main Features

1. International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

2. Adopt human-machine operation system.

3. Automatically stop when machine is overload.

4. Automatically reject lacking of package product and leaflet.

5.Automatically display trouble, alarm and count finished products.

6.Stable performance, operation is easy.

Main Technical Parameters

Item | Parameters | |

Encasing Speed | 30-120(boxes/min) | |

Box | Quality Requirement | 250-350g/m²Base on the size of carton. |

Dimension Range(L×W×H) | (65-125)mm×(30-85)mm×(12-50)mm | |

Leaflet | Quality Requirement | 60-70g/m² |

Unfolded Leaflet Specification | (L×W)(80-250)mm×(90-170)mm | |

Fold Range(L×W) | (1-4)(Fold) | |

Compressed Air | Working Pressure | ≥0.6mpa |

Air Consumption | 120-160L/min | |

Power Supply | 220V 50HZ | |

Motor Power | 0.75kw | |

(L×W×H) Dimension of Machine | 1380×1140×1800 | |

Weight | 1000kg | |

RP-TMMP-60A Transparent Film Three Dimension Packing Machine

Introduction

This machine is widely used in pharmaceutical, food, health supplies, cosmetics, daily necessities, stationery, playing cards, etc. It is used in the various items in the package collection box or a single box that completely closed automatically packaging. This product has the function of “three against and three improvements”, that is anti-counterfeiting, moisture-proof, dust-proof; upgrade products, improve value-added products, improve product quality and appearance of decoration. This machine adopts imported PLC control, electrical machine integrated operating system. It is reliable and easy to use. It is the advanced three-dimensional packaging equipments for the cassette collection packaging and the large items packaging.

Main Features

1.It is of compact structure, stable operation and easy maintenance.

2.It adopts multi-function digital converter, variable speed.

3.It is easy to replace the mold.

4.Automatically feeding and counting.

5.The transmission equips with protective device and fault tips.

Model | RP-TMMP-60A |

Packing speed | 40-80 bags/min |

Wrapper | BOPP tobacco film and tear tape |

Packing size | L:50-240mm W:20-120mm H:10-60mm |

Outline dim. | 2000×790×1550 |

Weight | 650kg |

Power | |

Voltage | 220V/(50Hz) |

RF-BMKZ-20AH Automatic High-speed Film Strapping Machine

Introduction

This machine can unscramble the carton, then film strapping the carton. It is composed of the conveyor, up straight carton device, stack box mechanism, push box mechanism, tight film mechanism, press film mechanism, hot cutting mechanism, electric control mechanism, pneumatic system and operation control. It is mainly used for film strapping in pharmacy, foodstuff industry.

Main Features

1. Compact structure and stable.

2. Running stable, low noise.

3. Adapt frequency converter for adjusting the speed, convenient to adjust.

4. Intelligent control system, safe and reliable.

Model | RF-BMKZ-20AH

|

Carton size range | L: 70~150*W :50~120*H: 15~50mm |

Throughput | ≤20bags/min |

Gas source | 0.7MPa |

Banding pattern | 1*10,1*5 |

Power | 0.5kW |

Power Supply | 220V/50Hz |

Dimensions | 1130*770*1150mm |

Weight | 400kg |