DPP-260 GMP CE High Speed Flat Plate Pill Capsule Tablet Blister Packing Machine

Model of blister pack packing machine | DPP-260R |

Production capacity of blister pack packing machine | 18,000~236,000 pcs/hour |

Max. shaping Dia.And Depth | 250*160*15mm Max. Depth 26mm(custom-made) |

Blanking of blister pack packing machine | 20~180 blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

Power of Main Motor of blister pack packing machine | 1.5kW |

Total Power of blister pack packing machine | 6.0kW |

Power supply of blister pack packing machine | 380V/220V/50Hz |

Standard Travel Range | 40~160mm |

Standard Plate of blister pack packing machine | 80*57mm |

Dpp-260r automatic blister packaging machine for flat pills, capsules and tablets meets the requirements of GMP. This product has high stability. It is a best-selling automatic blister packaging machine in the market and the first choice of customers.

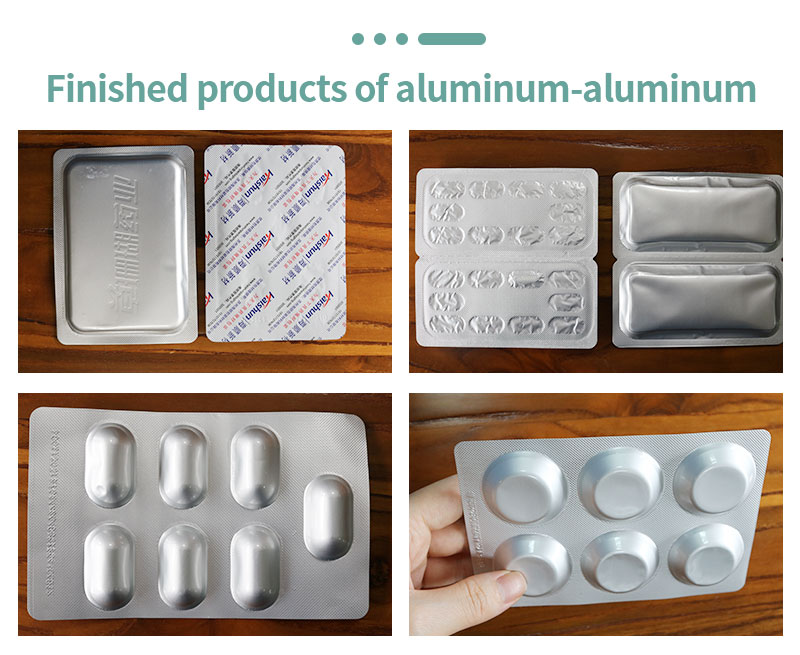

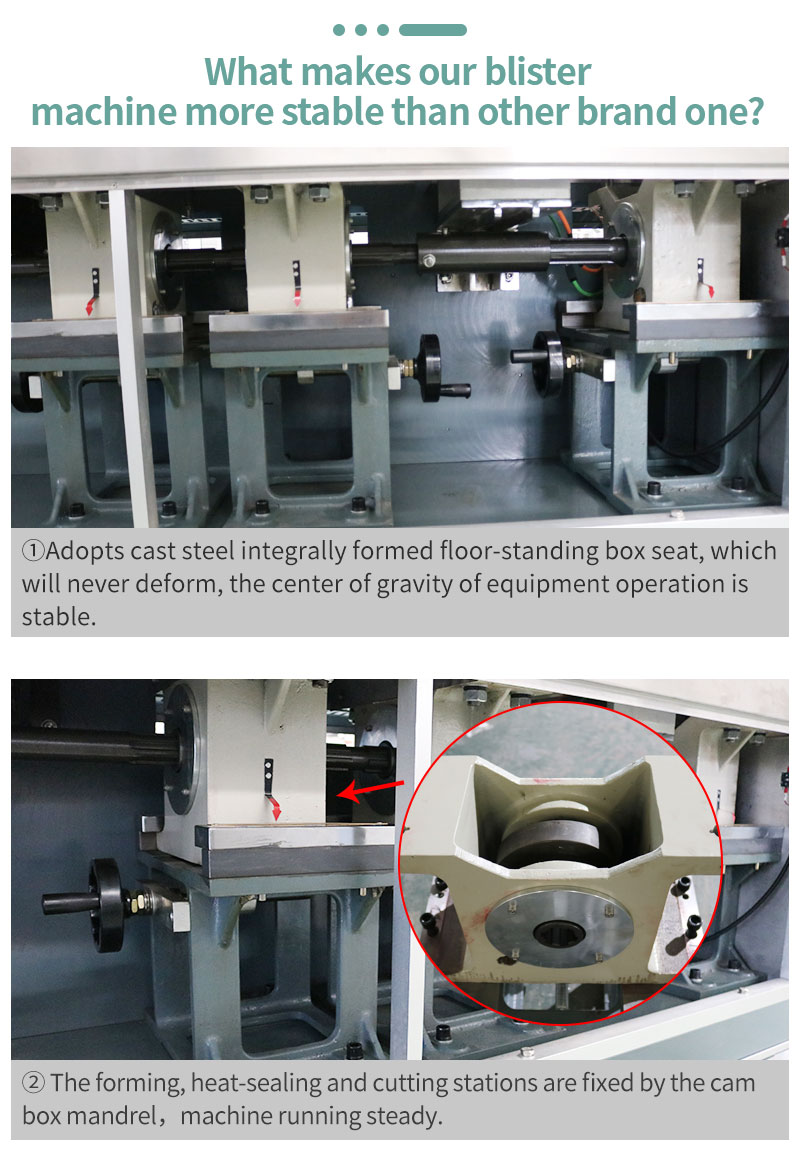

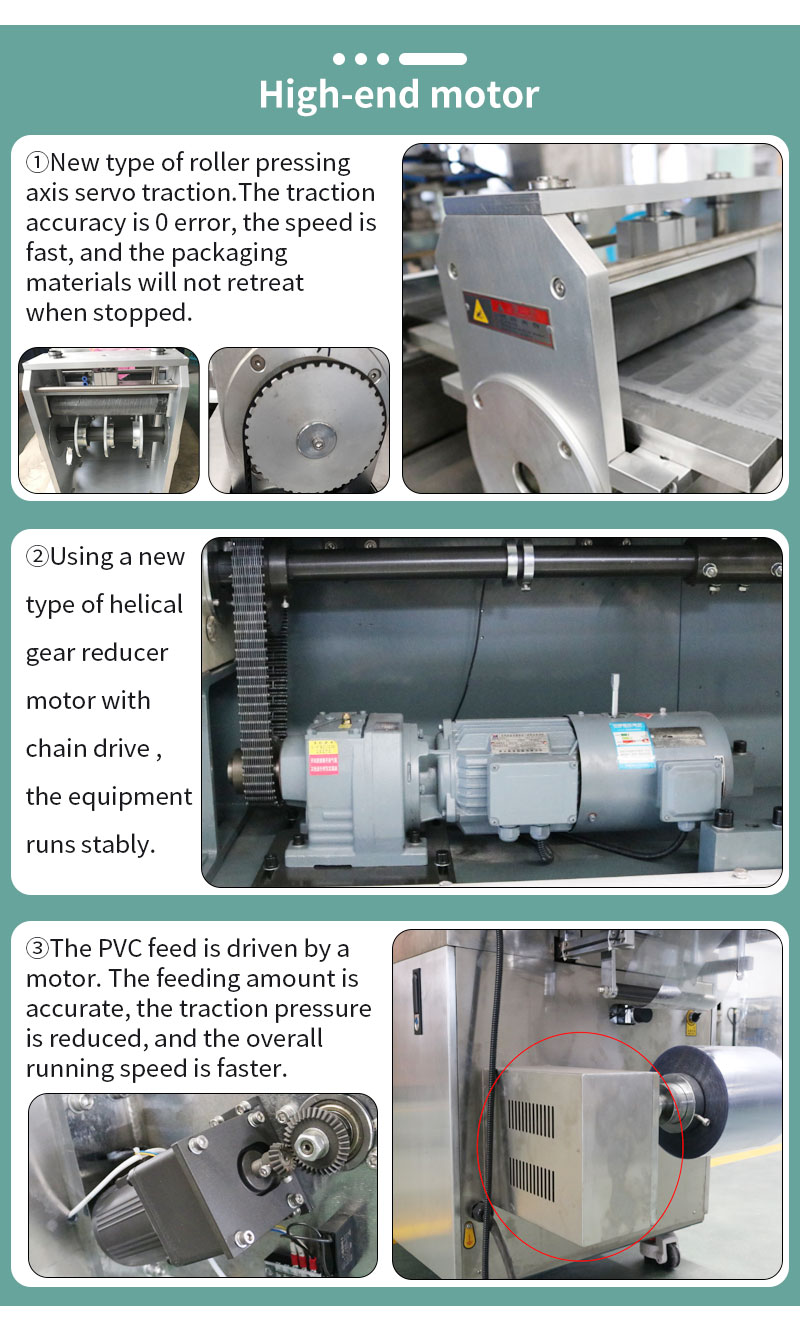

The product packaged by model 260 has good effect. It can not only complete the packaging of tablets, but also complete the packaging of candy, capsules and other different categories of materials for aluminum plastic or aluminum / paper plastic. In order to ensure the stability of 260 type equipment of blister packaging machine, the product uses the helical gear design of reduction motor. Each station is fixed by four columns. Other models do not have the function of this 260 capsule blister model.

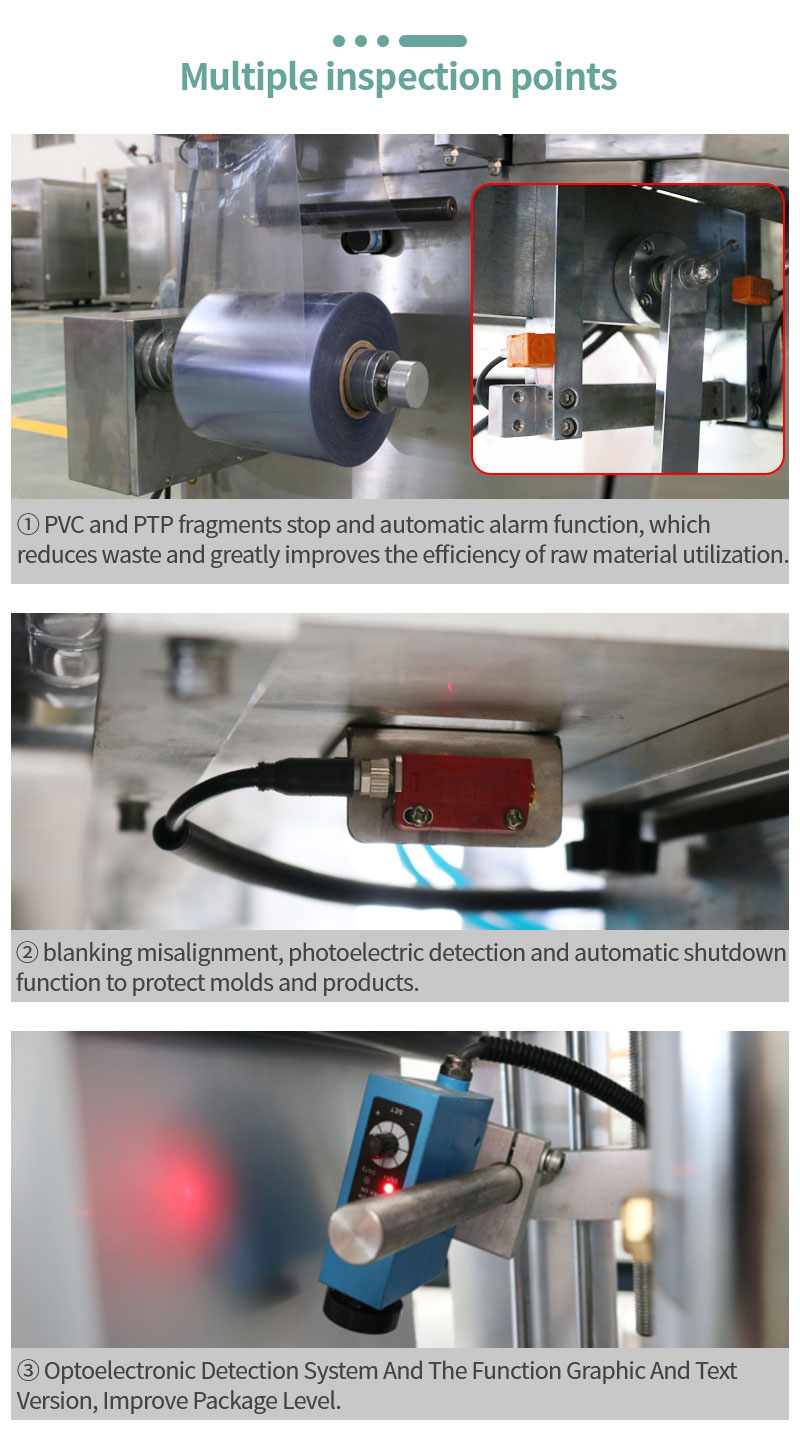

The overall operation of this model is simple, and the operation administrator can use it only through programming data design. The full-automatic blister packaging machine 260dpp adopts rich packaging, which will automatically stop the impact of PVC or PTP product rupture, and send out an alarm sound to reduce the waste of raw materials. Because the capsule blister packaging machine 260r has high stability and excellent performance, it meets the needs of customers to choose packaging machinery products.