DPP-160R is a brand new aluminum-plastic blister packaging machine specially developed by our company for pharmaceutical factories. This machine is driven by a full servo motor and is programmable by PLC. It can be used for tablets, capsules, candies, electronic cigarettes, soft Capsules, candies, big pills, injections and other materials are automatically packed. It is an aluminum-plastic/paper-plastic, aluminum-aluminum dual-purpose model. It has the functions of fully automatic forming, feeding, sealing, punching, counting, and batch number coding, which meets GMP production requirements.

Model | DPP-160R |

Blanking | 20~50 times/min |

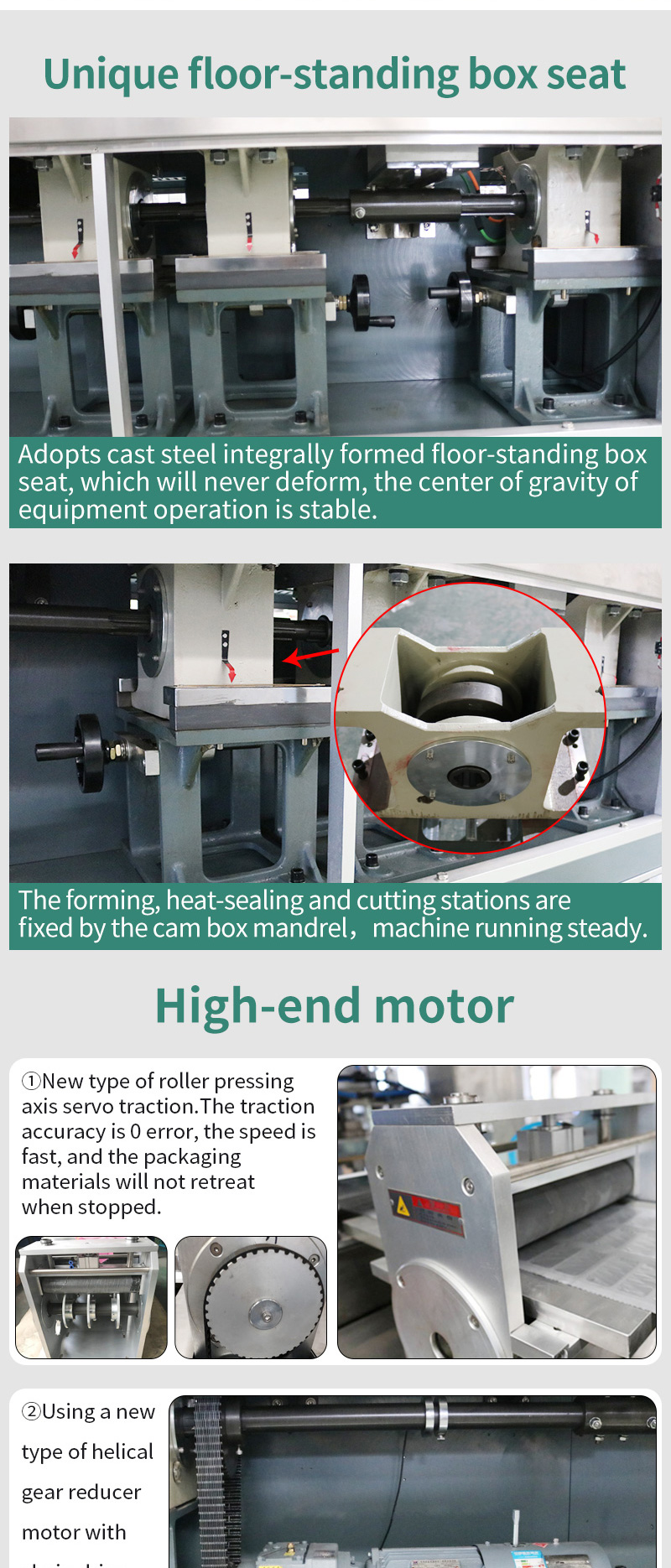

Production Capacity | 1200-4200 plates/h |

Max. Shaping Dia. And Depth | 130*100*15mm Max. Depth 26mm(custom-made) |

Standard Travel Range | 40~110mm |

Standard Plate | 80*57mm |

Power ofMain Motor | 1.5kW |

Total Power | 3.78kW |

Power | 380V/220V/50Hz |

Vacuum | 0.4MPa-0.6MPa |

Noise | <75dBA |

Thickness and Width of PVC | 140×0.25~0. 5mm |

Thickness and Width of PTP | 140×0.02~0.03mm |

Dialyzing Paper | 50~100g*150mm |

Mold Cooling | Runing water or circulating water |

Weight | Net weight 1600 kg ; |

Overall Size of Machine | 2510*750*1450 mm |

configuration list:

item | specification | manufacturer |

Servo motor | ECMA-C20807RS | Taiwan |

server Driver | ASD-B2-0721-B | Taiwan |

PLC main module | CP1L-M30DR-A | Omron |

PLC temperature module | CP1W-TSOO2 | Omron |

PLC touch screen | 6AV6/648-0BC11-3AX0 | Siemens |

Encoder | ZSP3806-003G-1500BZ3-5-24F | United States Rip Ann Waco |

Main motor | RC series helical gear motor | Geer |

frequency | VFD015M21A | Taiwan |

Stainless steel plate | 304 316 | Korea,japan |

Switching power supply | NES-100-24 | Taiwan mingwei |

emergency button | XB2-BS542 | Schneider |

1. Aluminum-plastic and aluminum-aluminum dual-purpose models have low operating costs and high cost performance.

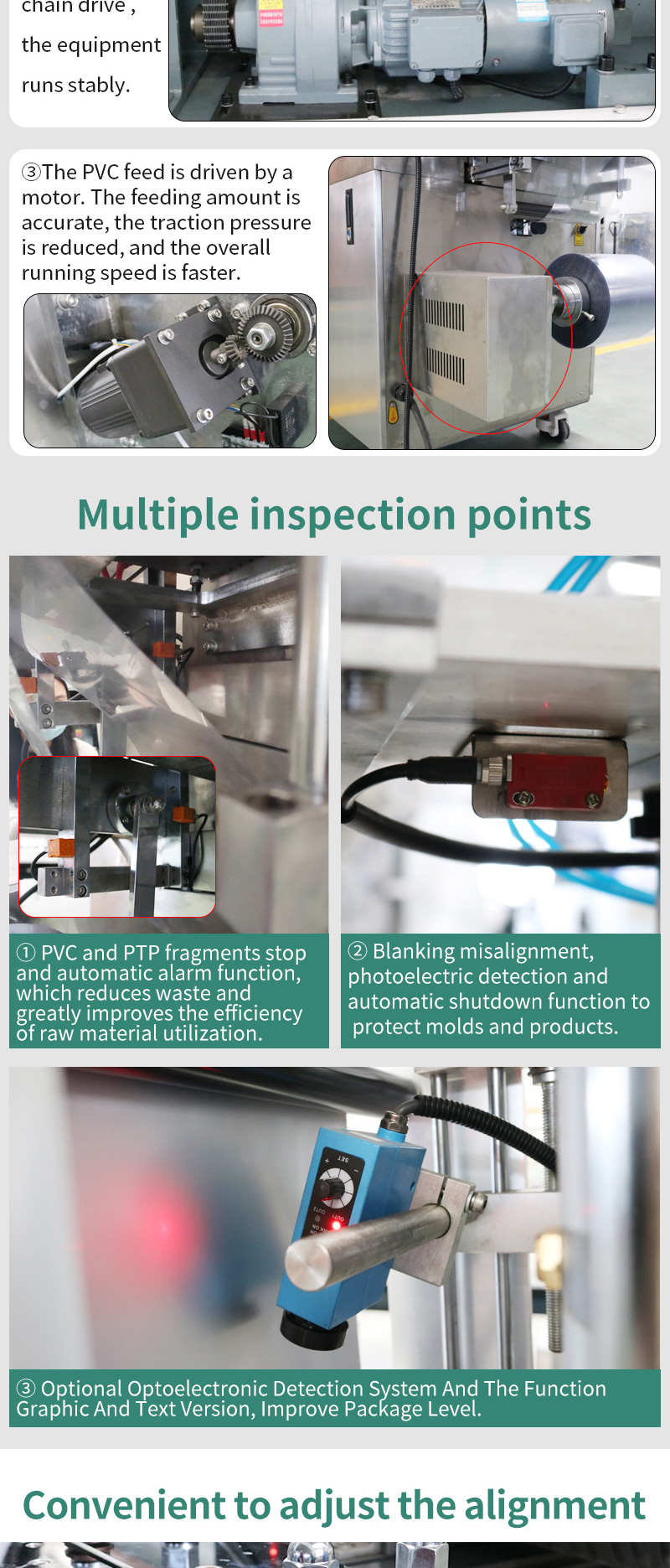

2. Adopt the new type of servo motor roller pressing shaft traction, the traction accuracy is 0 error, the speed is fast, and the packaging materials will not retreat when stopped.

3. The forming, heat-sealing, indentation and cutting station cam adopts cast steel integrally formed floor-standing box seat, which will never deform, the center of gravity of equipment operation is stable, and the adjustment of each station is light and accurate.

4. DPP-160 blister packing machine adopts a large platform design. The power transmission and cam box are all built-in under the body, which is convenient for cleaning and maintenance after use.

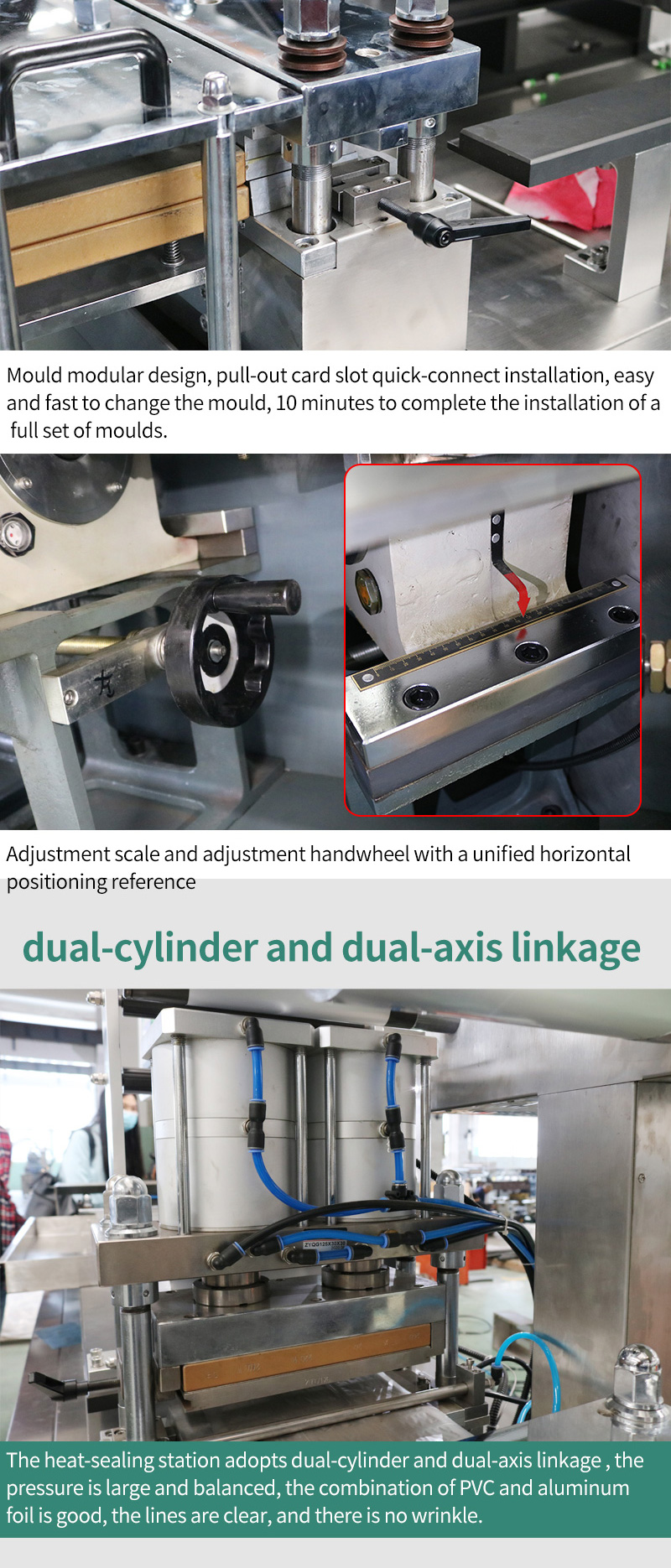

5. PVC and PTP fragments stop and automatic alarm function, which reduces waste and greatly improves the efficiency of raw material utilization.

6. Mould modular design, pull-out card slot quick-connect installation, easy and fast to change the mould, 10 minutes to complete the installation of a full set of moulds.

7. The forming, heat-sealing and cutting stations are fixed by the cam box mandrel, with a unified horizontal positioning reference and adjustment scale, which is convenient for customers to adjust the alignment.

8. Forming, heat-sealing, and cutting stations are equipped with safety covers to protect the safety of operators.

9. The material has a wide range of applications, and it can be produced using PVC, PS, PET and other materials.

10. Equipped with blanking misalignment, photoelectric detection and automatic shutdown function to protect molds and products.

11. The PVC feed is detected by photoelectricity and driven by a motor. The feeding amount is accurate, the traction pressure is reduced, and the overall running speed is faster.

12. The heat-sealing station adopts dual-cylinder and dual-axis linkage, the pressure is large and balanced, the combination of PVC and aluminum foil is good, the lines are clear, and there is no wrinkle.

13. Using a new type of helical gear reducer motor, the equipment runs stably.

14. Chain drive, low noise, less than<75dBA.

15. The electrical appliances adopt famous brand products, and the centralized modular design is convenient for maintenance.

16. Each station is fixed by four uprights for better stability.

17. With emergency stop device, you can stop immediately in case of emergency.

18. Equipped with waste recycling device to improve production efficiency, keep the workshop clean and meet GMP standards.

19. Optional photoelectric detection system and image-text matching function to improve packaging quality.