Introduction

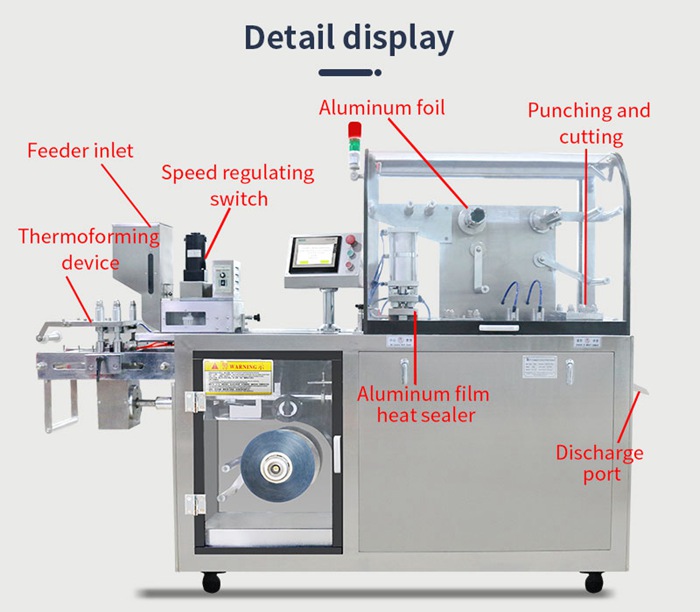

DPP-160 is an automatic blister packaging machine that automatically packs pharmaceutical tablets, food candy, daily electronic cigarettes and other solids, perfumes, sauces and liquids into aluminum-plastic/aluminum-aluminum panels. It is made of aluminum. Plastic/paper-plastic, aluminum-aluminum dual-purpose models, low cost and high cost performance.

| dpp-160 | |

| suit for | liquid or tablet capsule pills |

| number of times | 10~35 times/min |

Production capacity (according to one punch and two plates) | 1200-4200 plates/hour |

| Maximum forming area | 130*100*15mm |

| pvc and PTP size of width | 150mm |

| Dialysis paper of blister packer | (50-100g)*150mm |

Using a new type of high-power gear motor, the motor has a brake function, the operating stroke is accurate, the mold runs to the highest point during the debugging process, and it will not rotate, which is convenient for adjustment

The forming, traction, and positioning modules adopt proximity switch control instead of pneumatic component control, with higher accuracy

Each station is fixed by four uprights for better stability

Equipped with emergency stop device and safety warning light

Each station is adjusted by rotating hand wheel and equipped with a scale, which is convenient, fast and accurate

The heat-sealing station is driven by the cylinder, which runs accurately and is convenient for operation

Equipped with indentation device, convenient for customers to use

Equipped with a waste recycling device to improve production efficiency, increase material utilization, and be more environmentally friendly and save