Full Automatic DPP Mini Small Pharmaceutical Blister Packing Machine For Packaging Medicine Tablets Capsules Pills

After-sales | Engineers Available To Service Machinery Overseas | ||

Model | DPP 90R | DPP 130 | DPP 160R |

For | Tablet Capsule Pill Pod Liquid Butter Sauce Honey and etc. | ||

Plate/Hour | 2300 | 2400 | 4800 |

Max. Shaping/mm | 80*110 | 80*110 | 100*130 |

Automatic medicine plate blister packaging machine is a new structure pill blister machine developed by our company, which is a dual-purpose model of aluminum plastic and aluminum. Aluminum blister machine has low operation cost and high cost performance. The pill aluminum-plastic packaging machine can package pills, health products, pharmaceuticals, pills and big honey pills. The multi station automatic blister machine is synchronous and stable, and the proximity switch accuracy of the aluminum-plastic blister machine is higher. The drug blister packaging machine uses a photoelectric control system, which has the functions of PVC automatic feeding and waste recycling. The workshop is clean and the machine is easy to clean. It is a product that meets the requirements of GMP production.

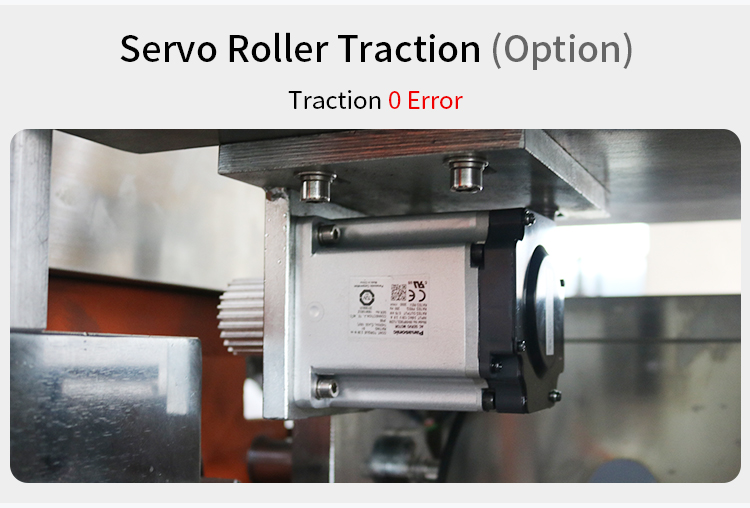

Pharmaceutical blister packaging machine that can package capsules, candy, tablets, electronic cigarettes and other products, aluminum plastic blister packaging machine servo motor traction 0 error, pharmaceutical blister packaging machine PLC intelligent screen control, automatic tablet blister packaging machine is paper plastic, aluminum plastic and aluminum and other multi-purpose machines, the production capacity can reach 2300 versions per hour, the blanking times can reach 10 to 40 times a minute, the molding depth and molding area of the machine are 80 * 110 * 15mm, The depth can reach 26mm (product customization service can be carried out according to customer needs).

Therefore, the small Blister Blister packaging function helps customers (mostly used in daily necessities, pharmaceutical and food industries) quickly and efficiently solve the problems of packaging products, working time and labor cost. It is also one of the important factors for customers in pharmaceutical, food, daily necessities and other industries. important factors for customers in pharmaceutical, food, daily necessities and other industries.