Introduction

This machine is suitable for blister packing tablet, capsule, pill, injection and other medicine, food, electronic component in pharmaceutical, foodstuff, medical equipment, cosmetics, health products and handicrafts and so on.

Main Features

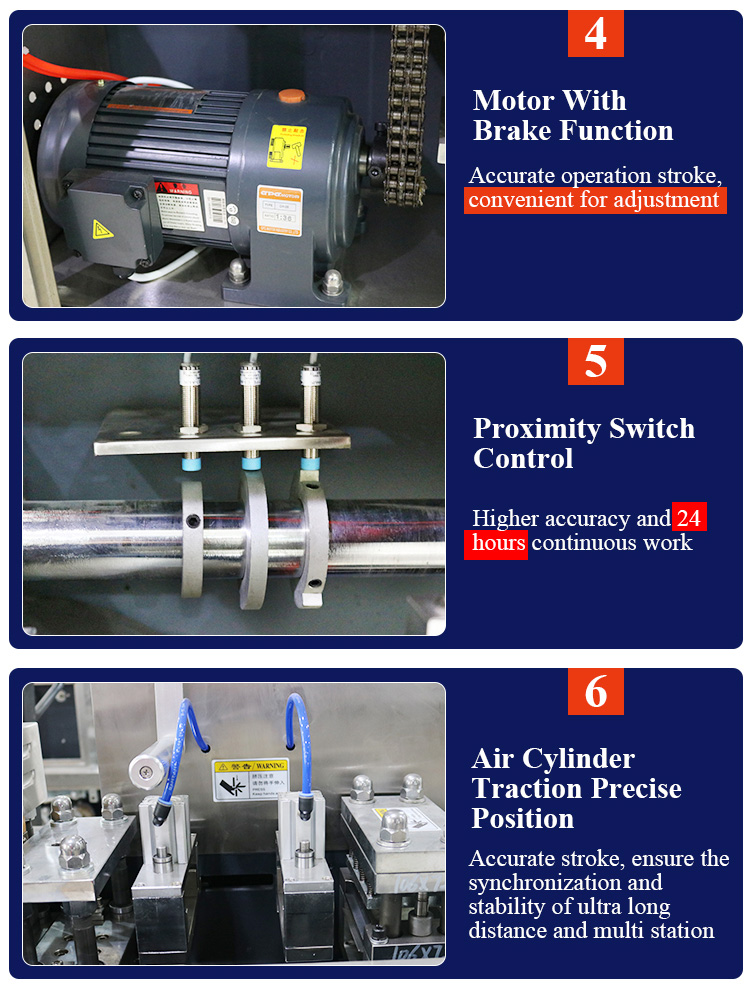

1.This machine adopts the latest model of high-power transmission, the row chain drive the transmission shaft, which eliminates the other gear transmission error and noise.

2.Electrical adopts the imported control systems, which can be customizing by the user. Equipped with the short shot up leakage device, missing particle detection and removed device (Omron Sensor). Adopts imported converter.

3.This machine adopts photoelectric system: PVC、PTP、tropical aluminum packaging and automatic feeding、waste selvage automatic material receiving device, which ensure the long-distance multi-site synchronization stability.

4.This machine adopts sub-portfolio structure: PVC informing、feeding、hot sealing; Tropical aluminum cold forming、hot sealing、blanking.

5.This machine can be equipped with reprovision photoelectric detection and corrected device, equipped with imported stepper motor, photo printing and packaging, which will optimize the grades of packaging.

6.Application: capsule, tablets, pill, injection and other medicine and food, electronic components blister sealed packaging.

Model | DPP-120 |

10~33 times/min | |

Production Capacity | 2400 plates/h |

Max. Shaping Dia. And Depth | 125*80*15mm Max. Depth 25mm(custom-made) |

Standard Travel Range | 30~80mm |

Standard Plate | 80*57mm |

Power of Main Motor | 0.75kW |

Total Power | 2.4kW |

Power | 380V/220V/50Hz |

Vacuum | 0.4MPa-0.6MPa |

Noise | <75dBA |

Thickness and Width of PVC | 0.15~0.5*120mm |

Thickness and Width of PTP | 0.02~0.035*120mm |

Dialyzing Paper | 50~100g*120mm |

Mold Cooling | Runing water or circulating water |

Weight | Net weight 590 kg ;Gross weight 650 kg |

Overall Size of Machine | 1830*580*1050 mm |

Packing Size | 1600*750*1200mm |