DPP-160Pro Automatic Aluminum Plastic Tablet Blister Packaging Machine

Model | DPP-160Pro |

Production Capacity | 4,200 blisters/hour |

Power supply | 380V/220V/50Hz |

Advantages | High Capacity, Modular Design |

Model | DPP-160Pro |

Production Capacity | 4,200 blisters/hour |

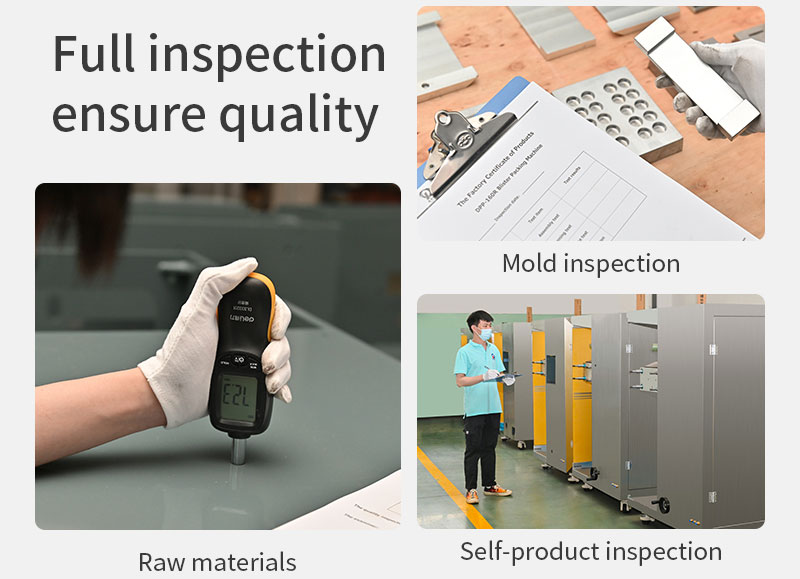

The aluminum-aluminum and aluminum-plastic double-purpose special-shaped tablet blister packaging machine can pack preparations, tablets, pills, and capsules. The aluminum-plastic automatic blister packaging machine. The pill blister packaging machine can pack products with high quality and fast, so the pharmaceutical industry, food industry and supplies industry have more and more demands, because this model has low operating cost and high cost performance.

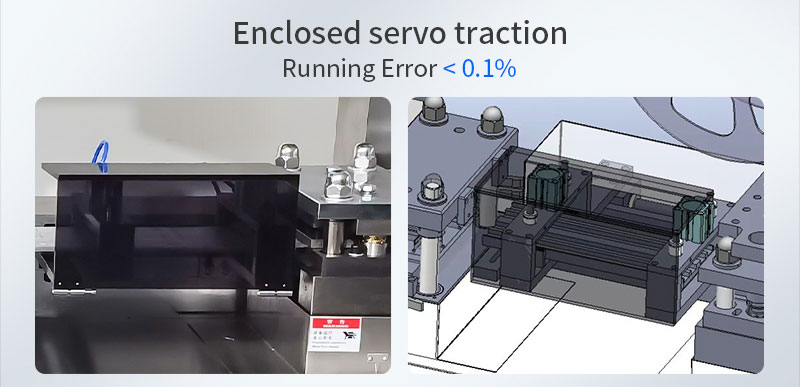

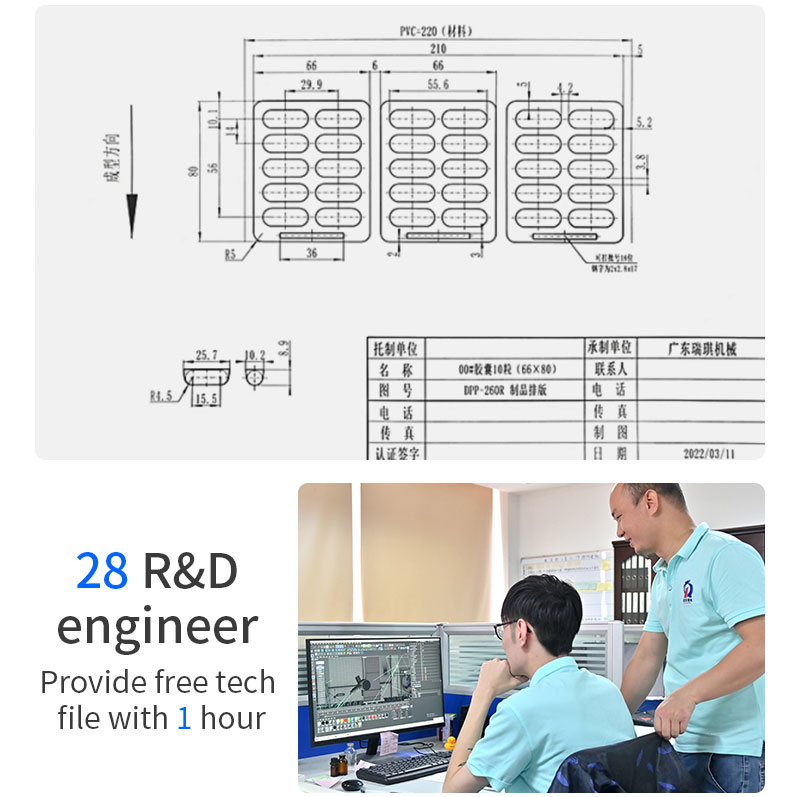

The soft capsule blister packaging machine is controlled by a smart screen PLC, and it can simply complete the work by simply touching the PLC screen for operation. The 160Pro flat-bed aluminum-plastic blister packaging machine has high servo motor traction precision, and each station adopts a mandrel positioning design (at the same time, the cursor alignment function can be selected according to customer needs), and can be freely adjusted by external handwheels and precise scales. Therefore, the adjustment and alignment of each station can be performed quickly and accurately.

The multifunctional aluminum-plastic packaging machine is a new type of structural aluminum-plastic automatic blister packaging machine upgraded by Guangdong Rich packing, which can be suitable for packaging capsules, preparations, tablets and tablets and other products. The equipment adopts an advanced control system and an integrated design of cylinder traction, which greatly helps customers to complete product packaging efficiently and solves the resulting labor costs, working hours and other problems.