DPP-160Pro Automatic Flat-plate Aluminum-plastic Blister Packaging Machine

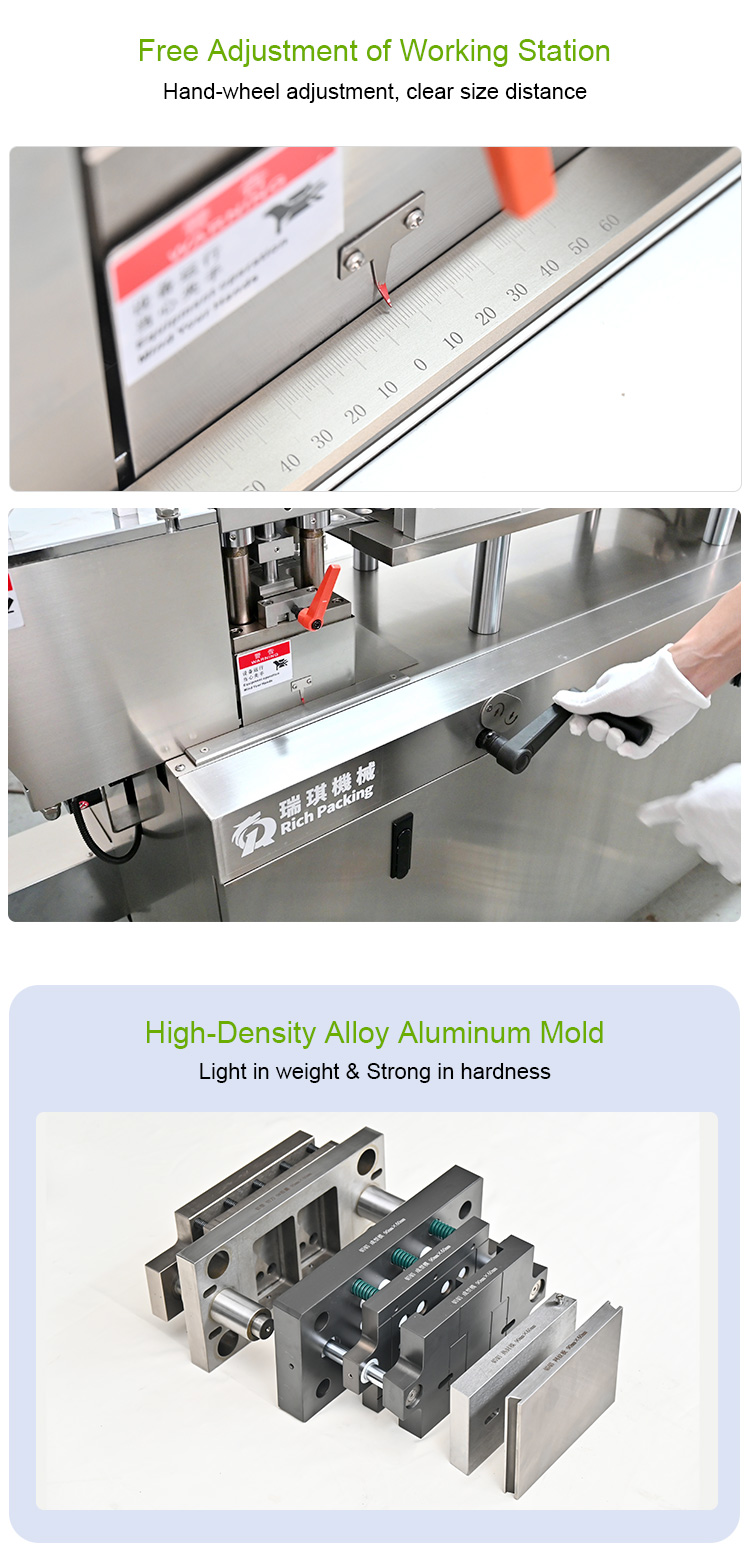

Modular Design: The modular configuration empowers the packaging machine to be customized and set up according to specific production requirements. Rapid mold replacement, tailored to the characteristics of the drug and packaging needs, enhances operational efficiency.

Working Principle: The main working principle of the blister packaging machine involves placing the product on the conveyor belt, then covering it with a foam cover and sealing it with heat shrinkable film to create an airtight package.

Main Stations in Blister Packaging Machines:

Forming Station: Heats the foam plastic to form it into a cover that fits the product's shape.

Heat-Shrinkable Film Sealing Station: Applies heat to the shrinkable film, which is then placed over the foam cover and shrunk to seal the product.

Cutting Station: Cuts the heat shrinkable film to create individual product packages.

Outfeed Station: Moves the packaged product out of the packaging machine and sends it to the next workstation or packaging area.

In an automated production line, the blister packaging machine can be integrated with other automated equipment, such as automatic box packing machines and coding machines, to achieve efficient automated production processes.

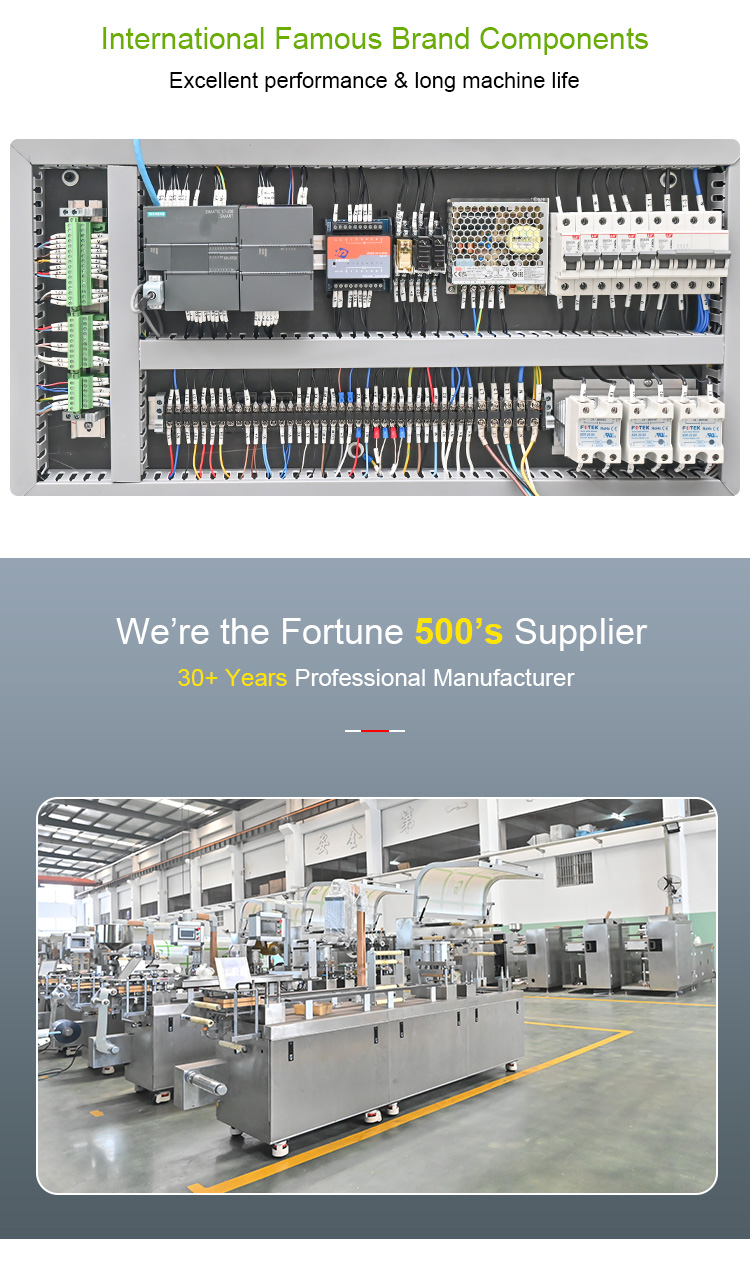

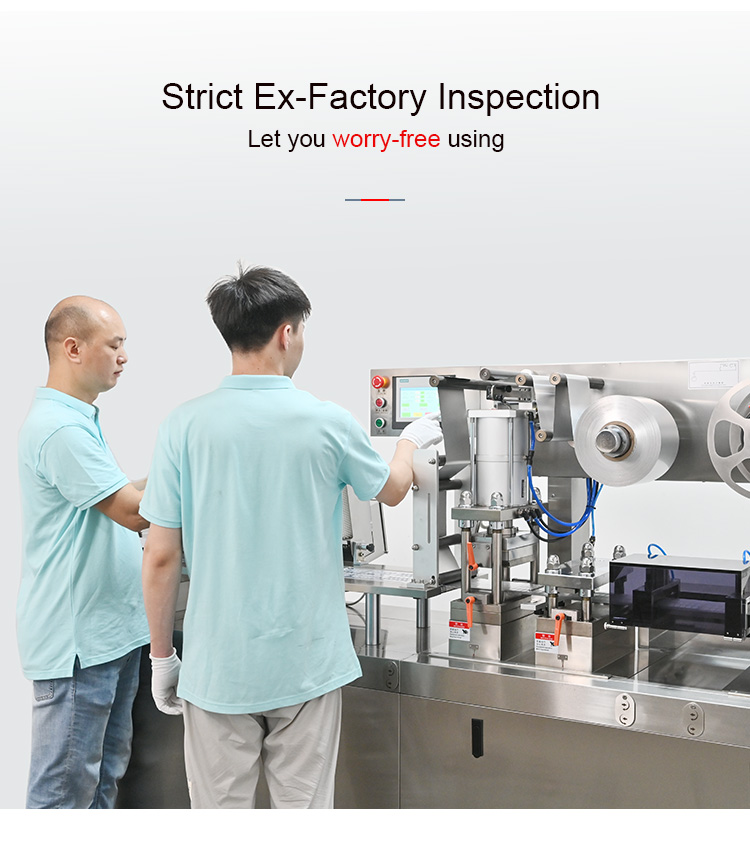

Furthermore, the design and functionality of the DPP-160pro blister packaging machine can be customized to align with specific requirements. For detailed and up-to-date information, direct inquiries can be made via WhatsApp & WeChat: +8613826093596 to obtain precise insights into this packaging machine.