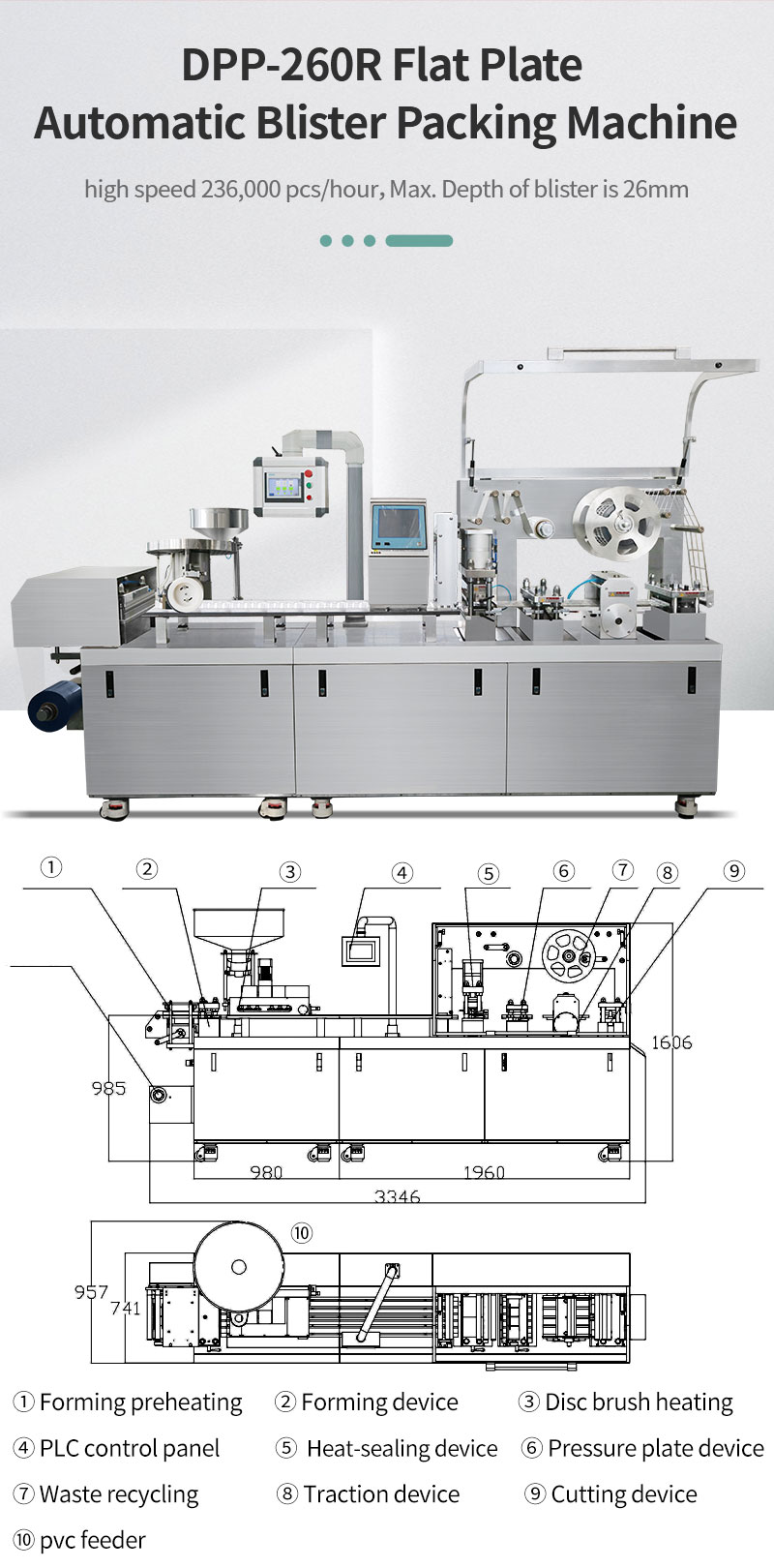

Model of blister package machine | DPP-260R |

Max. Production Capacity | 4400 pcs/min |

Max. Shaping Dia. And Depth | 250*160*15mm Max. Depth 26mm(custom-made) |

Blanking of blister machine | 20~180 blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

Power of blister machine Main Motor | 1.5kW |

Total Power of blister machine | 6.0kW |

Power supply of blister machine | 380V/220V/50Hz |

Standard Travel Range | 40~160mm |

Standard Plate of blister machine | 80*57mm |

Thickness and Width of PVC | 260*0.15~0.45mm |

Thickness and Width of PTP | 260*0.02~0.03mm |

Dialyzing Paper of blister machine | 50~100g*260mm |

Vacuum of blister machine | 0.4MPa-0.6MPa |

gas consumption of blister machine | ≥0.2m3/min |

Noise of blister machine | <75dBA |

Mold Cooling of blister machine | Runing water or circulating water |

Weight of blister machine | Net weight 2600kg |

Overall Size of blister Machine | 3500*740*1680 mm(L*W*H) The machine can be transported in 2 sections |

1.DPP-260R pill blister pack packing machine is controlled by the famous German Siemens PLC, with a frequency converter for adjusting speed, and the Siemens touch screen operation, with higher precision and more convenient operation.

2.latest modular design of the Richpacking DPP260R automatic Portable blister packing machine, pull-out card slot designment , can quickly install and change molds within only 10 minutes.

3.The 260R portable blister packing machine can automatically feed pills,tablets and capsule and other larger solids need to be manually unloaded.