Model of blister pack packing machine | DPP-260R |

Production Capacity of blister pack packing machine | 18000~236,000 pcs/hour |

Max. Shaping Dia. And Depth | 250*160*15mm Max. Depth 26mm(custom-made) |

Blanking of blister pack packing machine | 20~180 blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

Power of Main Motor of blister pack packing machine | 1.5kW |

Total Power of blister pack packing machine | 6.0kW |

Power supply of blister pack packing machine | 380V/220V/50Hz |

Standard Travel Range | 40~160mm |

Standard Plate of blister pack packing machine | 80*57mm |

Thickness and Width of PVC of blister pack packing machine | 260*0.15~0.45mm |

Thickness and Width of PTP | 260*0.02~0.03mm |

Dialyzing Paper of blister pack packing machine | 50~100g*260mm |

Vacuum of blister pack packing machine | 0.4MPa-0.6MPa |

gas consumption of blister pack packing machine | ≥0.2m3/min |

Noise of blister pack packing machine | <75dBA |

Mold Cooling of blister pack packing machine | Runing water or circulating water |

Weight of blister pack packing machine | Net weight 2600kg |

Overall Size of blister pack packing machine | 3500*740*1680 mm(L*W*H) |

DPP the 260R blister packaging machine can not only finish to the pack tablets, but also can the finish to pack capsules, the sweet candy and the other type the large size materials. At the same times, this 260 DPP the models have the multi-purpose the unctions, that is means it can be used for the aluminum or the aluminum the plastic / the dialysis paper plastic.

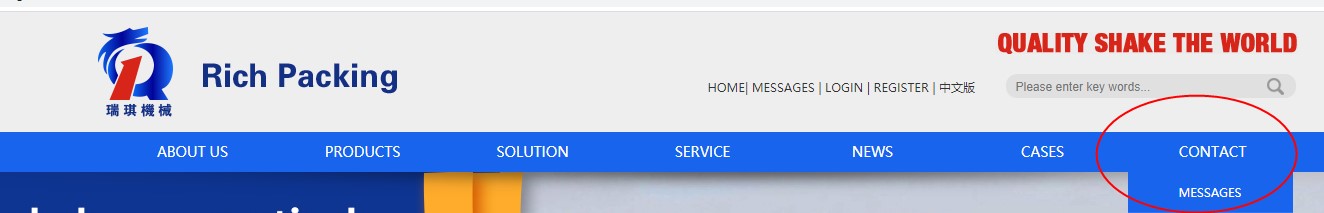

We the Rich Packing in order to improve the utilization rates of the these raw materials and the efficiency of the blistering machine production, when this materials the PVC and the PTP are broken, it will stop the automatically at the once and the DPP 260R will give an alarm to operators, so as in order to the reducing the squander of the materials. The operator by the programming the data, the system’s the operation is very simpler, and the PVC the feedings are detected by the photoelectric, the feeding the quantity is high accurate, and the blister packer machine runs quite the faster.

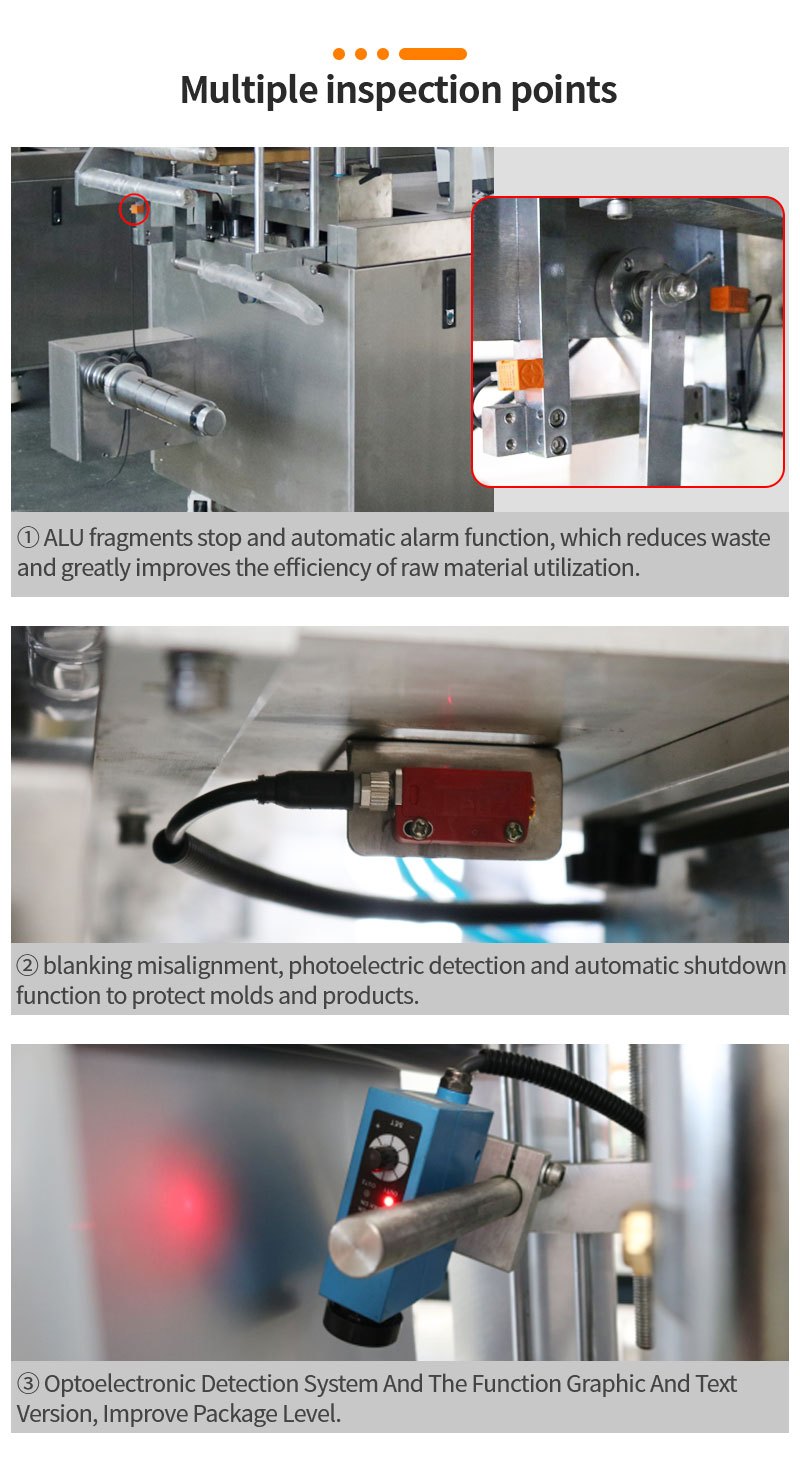

In order to the ensuring the 260 R type the stability of the equipment, we adopts the new helical gears of the reduction motor, and each of the 260R the station is fixed by four the columns.

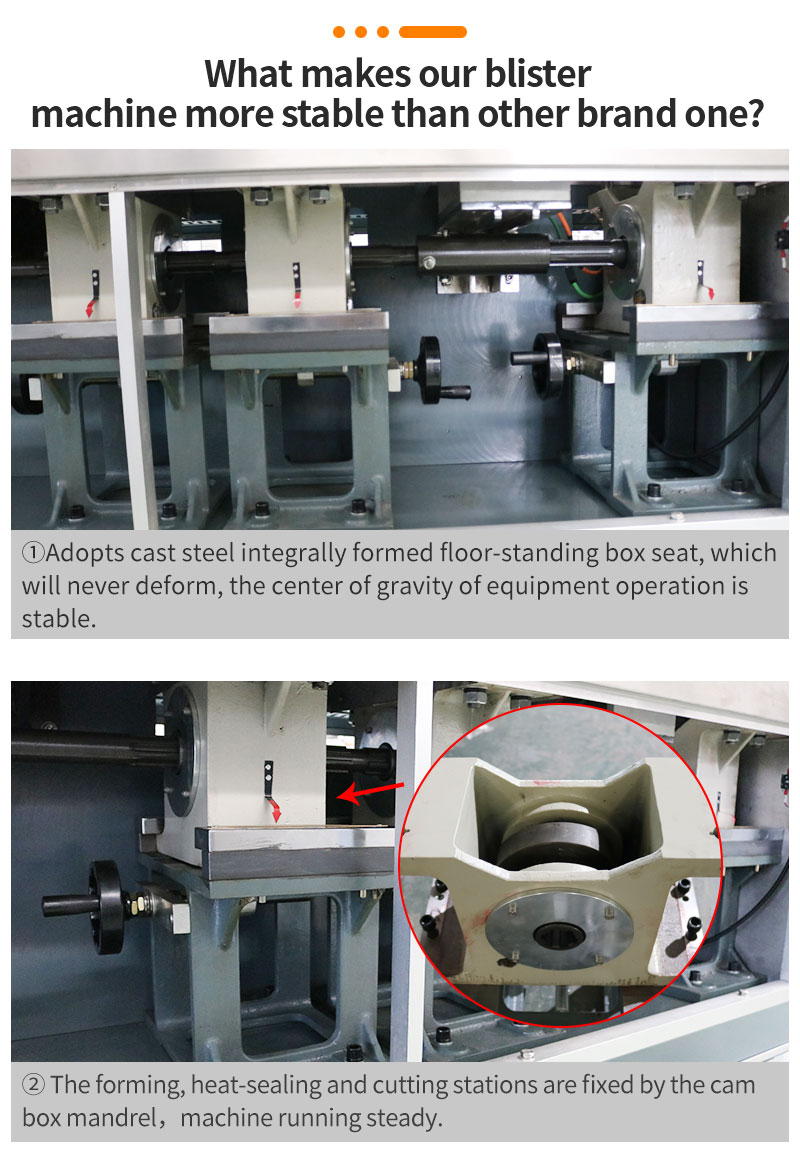

And in order to the ensure the convenience of the transportations and the installation of the blister capsule machine, the machine will adopt the split type the combination, these design make very easily and the simple to entering these elevators and to install simple. In the we RQ after-sales the service aspect, because what we buy the is the electrical appliances from all the famous the brand products, as the centralized the modular design, so the blistering machinery maintenance is the very convenient.