DSL-16R High Speed 16 Channel Gummy Counter

After-sales | Engineers Available To Service Machinery Overseas | |||

Counting Machine Model | RQ-DSL-8 | RQ-DSL-16 | RQ-DSL-16R | RQ-DSL-16H |

Applicable material | Φ3~25mm tablets,Φ3~25mm pills, 000~5# hard and soft capsules | |||

Power | 0.6Kw | 1.2Kw | 2.2Kw | 2.5Kw |

Max Capacity | 35 bottles/min | 105 bottles/min | 100 bottles/min | 130 bottles/min |

PLC | NO | NO | YES | YES |

Accuracy of rate | 98% | 98% | 99.97% | 99.98% |

Dimension(mm) | 1400*1650*1650mm | 1400*1650*1650mm | 1200*1550*1750mm | 1300*1950*1800mm |

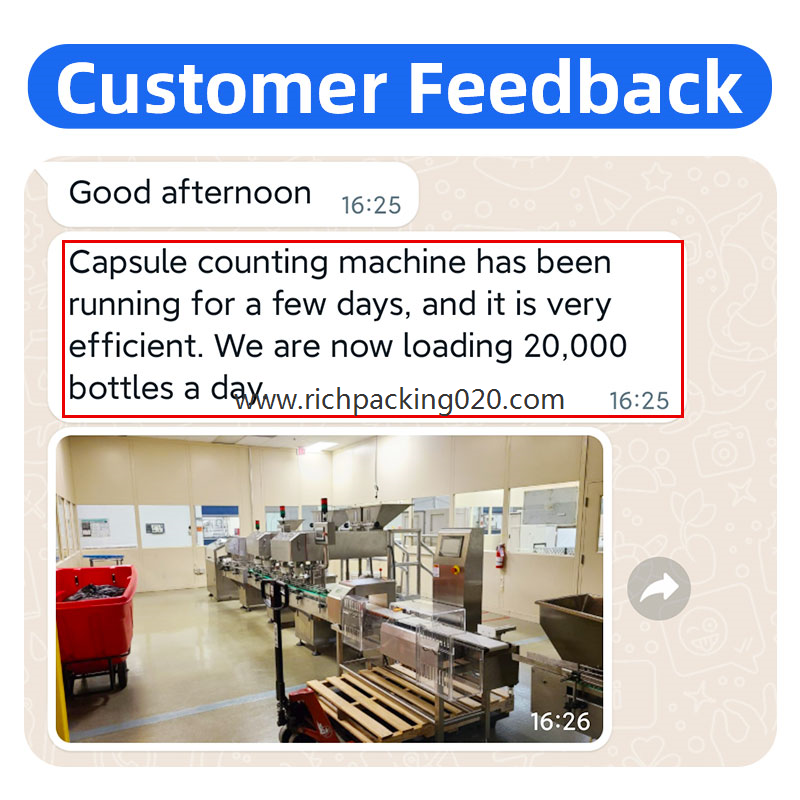

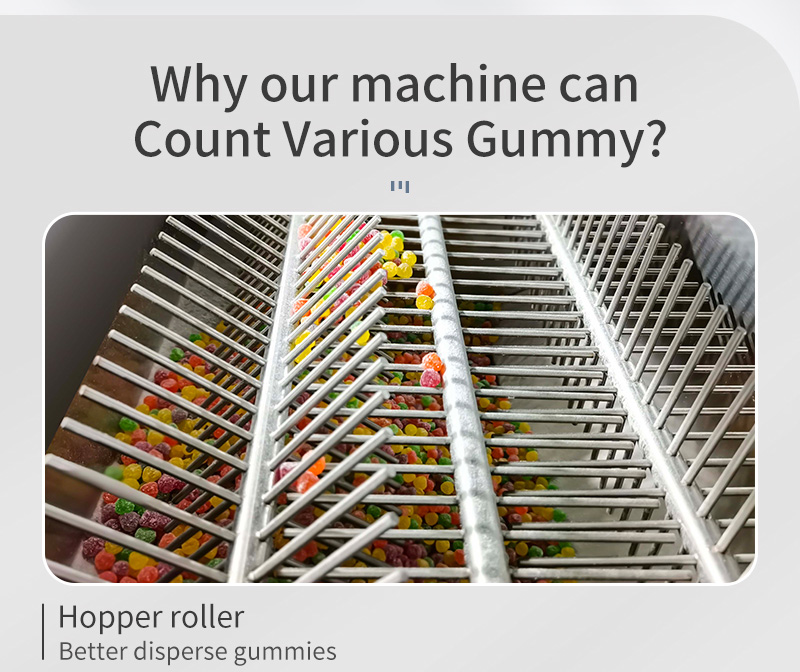

The standout feature of the 16 Lane Channel Gummy Counter is its impressive 16-lane counting system. This allows the machine to count and sort up to 16 lanes of gummies simultaneously, greatly increasing productivity and efficiency. With a gummies counting speed of up to 80 bottles per minute, it is perfectly suited for high-volume production.

Precision and accuracy are crucial when it comes to counting gummies, and this machine excels in delivering on both fronts. The advanced sensor technology and intelligent counting algorithms ensure consistent and accurate counts, minimizing any errors or discrepancies in the final product.

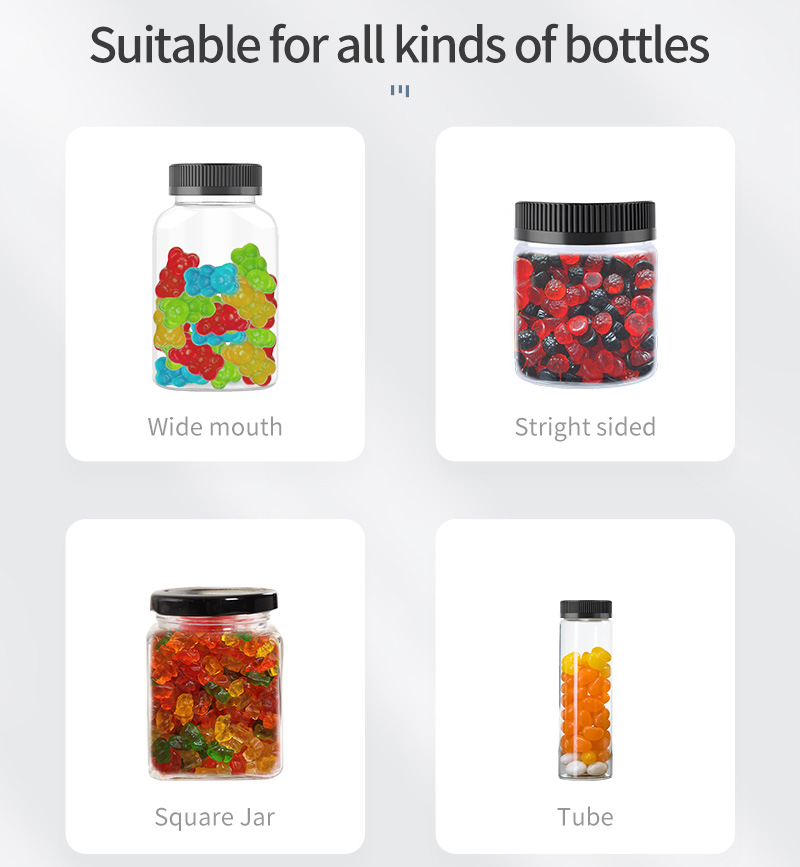

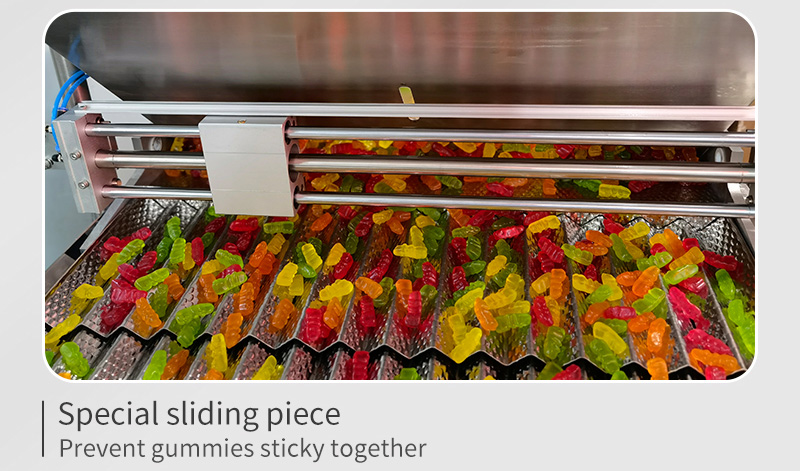

One of the key advantages of the 16 Lane Channel Gummy Counter is its ability to handle a wide range of gummy sizes, shapes, and textures. The machine's adjustable lanes and customizable settings allow for seamless adaptation to different gummy products, making it highly versatile and adaptable to various production needs.

In addition to its counting capabilities, the 16 Lane Channel Gummy Counter offers optional features such as automatic bottle filling and capping, further streamlining the packaging process. This enables seamless integration into existing production lines, enhancing overall productivity and reducing labor costs.

Overall, the 16 Lane Channel Gummy Counter is a cutting-edge machine that revolutionizes the gummy counting and packaging process. Its high-speed, precision counting, adaptability to different gummy sizes, and robust construction make it an indispensable tool for confectionery manufacturers seeking to enhance their production efficiency and deliver consistent, high-quality products to the market.