RQ-DSL 16 Rapid Gummy Channel Counter

Control system: the core part of the candy electronic counting machine, responsible for controlling the entire production process. The control system can realize the automatic operation of the equipment, monitor the production data in real time, and give an alarm to the abnormal situation.

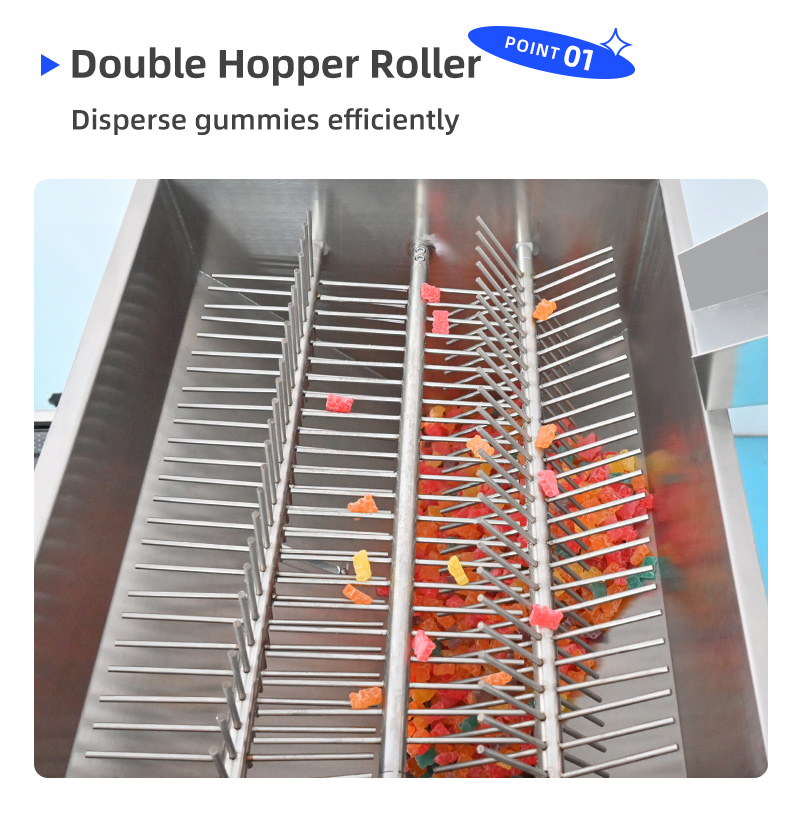

Conveyor system: responsible for conveying candy from the feed port to the weighing area. The conveying system can be adjusted according to production needs to accommodate different candy sizes and weights.

Weighing system: Weigh the candy passing through the conveying system to ensure that the weight of the candy meets the production requirements. The weighing system uses high-precision sensors to ensure the accuracy of measurement results.

Sorting system: Classify and sort the qualified candies according to the preset size and weight. The sorting system can effectively improve production efficiency and reduce labor costs.

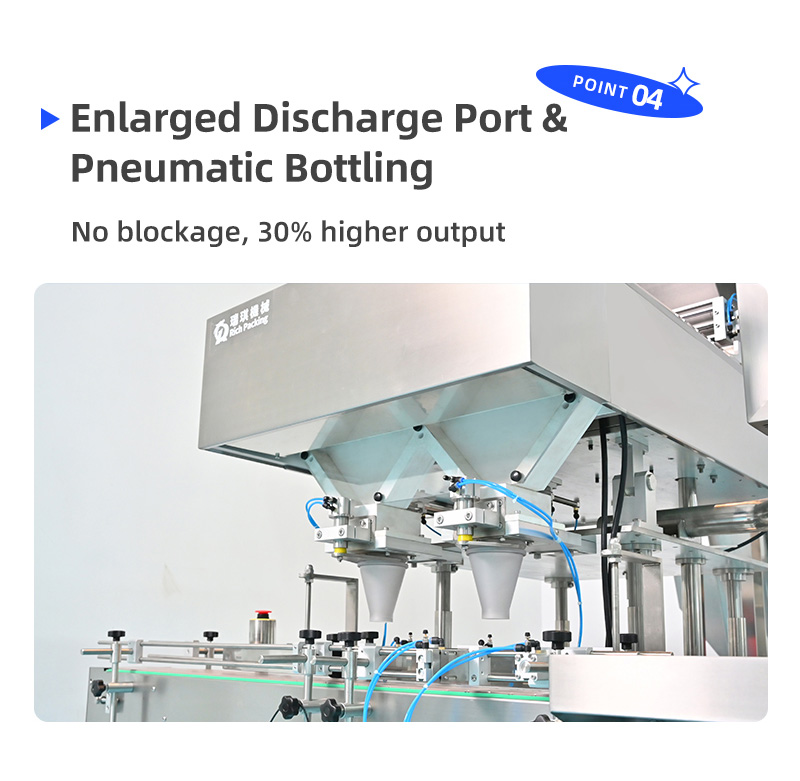

Packaging system: Pack the sorted and sorted candies to ensure that the candies maintain good quality during transportation and sales. The packaging system can choose different packaging methods and packaging materials according to customer needs.

Candy electronic counting machine has the advantages of high degree of automation, high production efficiency, simple operation, convenient maintenance, etc. It is widely used in food production enterprises such as candy, chocolate, and chewing gum.