DSL 8-lane Electronic Automatic Patent lollipop Cheese Stick Counting Machine

After-sales | Engineers Available To Service Machinery Overseas | |||

Counting Machine Model | RQ-DSL-8 | RQ-DSL-16 | RQ-DSL-16R | RQ-DSL-16H |

Applicable material | Φ3~25mm tablets,Φ3~25mm pills, 000~5# hard and soft capsules | |||

Power | 0.6Kw | 1.2Kw | 2.2Kw | 2.5Kw |

Max Capacity | 35 bottles/min | 105 bottles/min | 100 bottles/min | 130 bottles/min |

PLC | NO | NO | YES | YES |

Accuracy of rate | 98% | 98% | 99.97% | 99.98% |

Dimension(mm) | 1400*1650*1650mm | 1400*1650*1650mm | 1200*1550*1750mm | 1300*1950*1800mm |

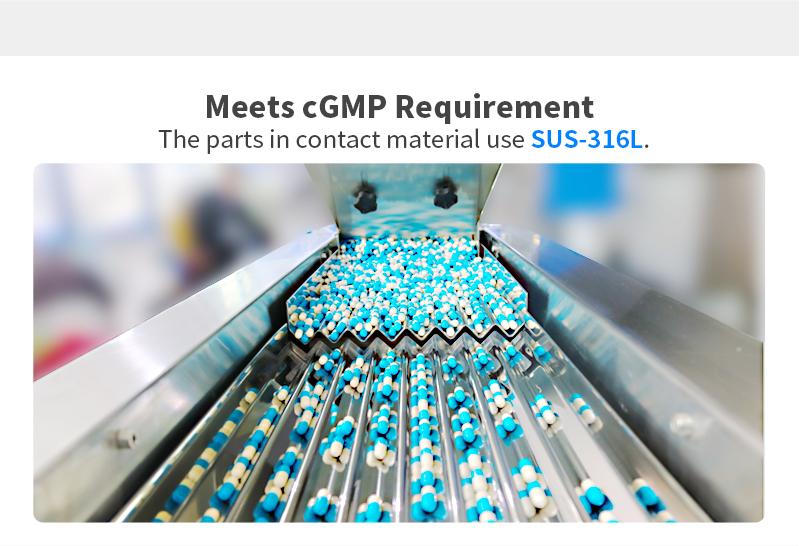

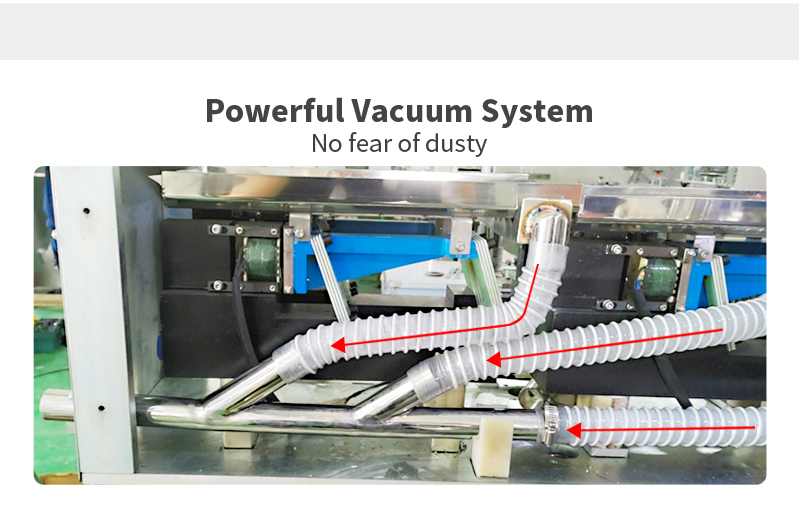

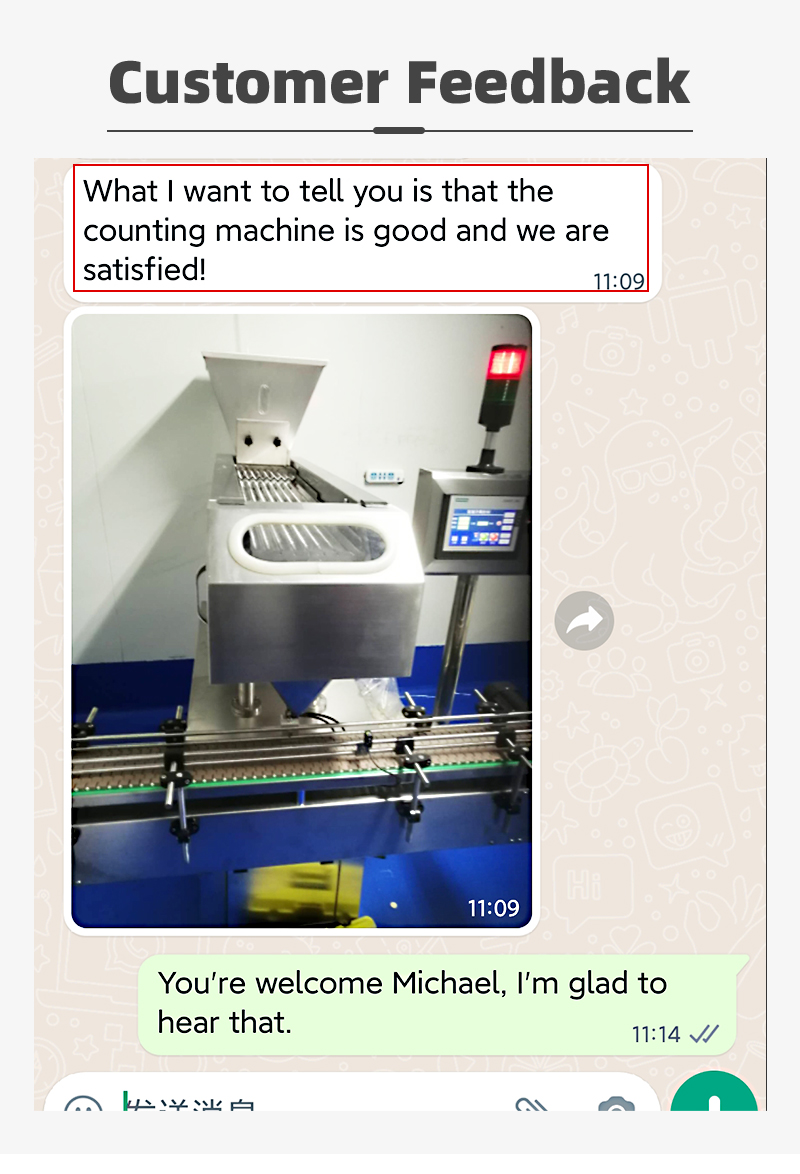

The full-automatic lollipop 8-lane electronic counting machine is a product iteratively updated by Richpacking company according to the needs of market users. The product updates the technical functions of high intelligence and high precision, which can accurately complete the task of counting lollipop cheese sticks. The body of this automatic patented cheese stick counting machine made in 8 countries is fully sealed, which can ensure no impact of dust interference, so it also reduces the cleaning work superimposed by the dust on the machine after use.

The full-automatic rq-dsl-8 Lane cheese stick electronic counting machine can be used in food (such as lollipop, cheese stick, soft candy, etc.) or in pharmaceutical and hospital industries (such as counting pills, tablets, capsules, etc.). The 8-lane lollipop counting machine with flexible adjustment of bottles of different sizes has automatic detection function, which can automatically detect and reject unqualified products during the operation of the equipment. Cheese stick counter rq-dsl-8 Lane granulator anti high dust high-power photoelectric detection (composed of 8 * 2 = 16 scanning photoelectric eyes), with accuracy > 99.97%.

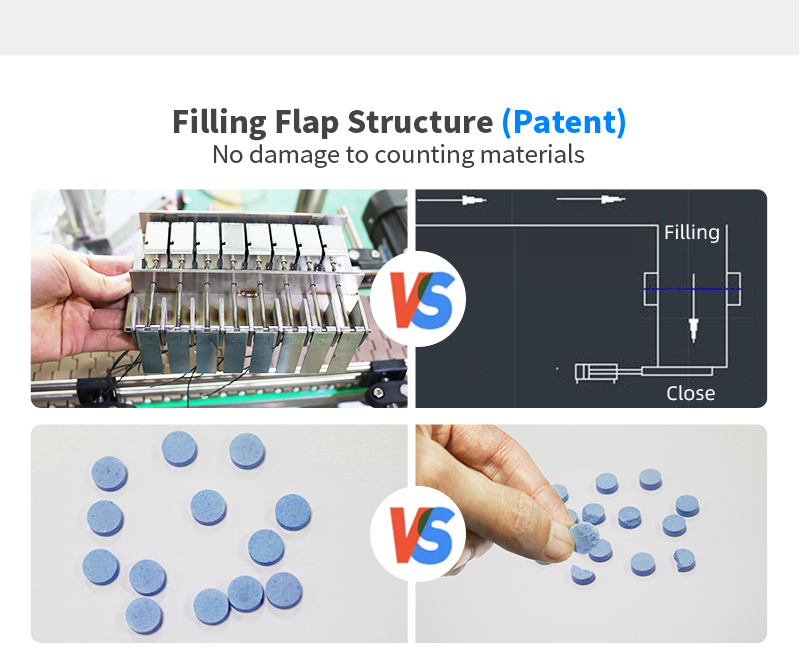

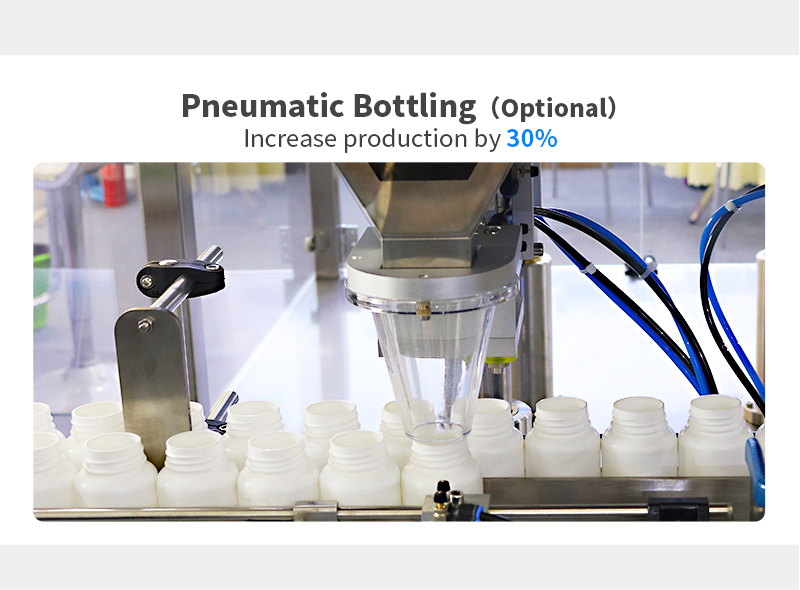

Lollipop automatic counting machine is a new generation of innovative automatic counting machine, which independently controls the counting and detection photoelectric (can carry out dynamic 360 degree scanning) products. The application and operation of the electronic counter is also very simple, and can flexibly adjust various functions; It only takes 10 minutes to replace bottle materials, and the machine noise is less than 75dBA (in line with GMP production requirements). This machine uses a new type of pneumatic blanking in the operation process, with high speed and no damage to materials. The machine is equipped with an emergency stop device to remind the function.