ZP 25 55D High Speed Double Pressure Rotary Tablet Press Machine

Model | ZP25D | ZP27D | ZP31D | ZP41D | ZP45D | ZP55D |

Dies No. | 25 | 27 | 31 | 41 | 45 | 55 |

Max. Pressure | 100kn | 100 kn | 100 kn | 100 kn | 100 kn | 100 kn |

Max. Dia. of Tablet | 25mm | 20 mm | 20 mm | 13 mm | 11 mm | 9 mm |

Max.Depth of Filling | 6mm-30 mm | |||||

Max.Thickness of Tablet | 0.5mm-15 mm | |||||

Rotary Speed | 5-30r/min | |||||

Max. Production Capacity | 90000 pc/h | 97200 pc/h | 111600pc/h | 172000pc/h | 189000pc/h | 230000pc/h |

Power | 4.5-5.5kw | |||||

voltage | 220v/380v 50Hz | |||||

size | 1240*850*1850mm | |||||

Weight | 1850kg | |||||

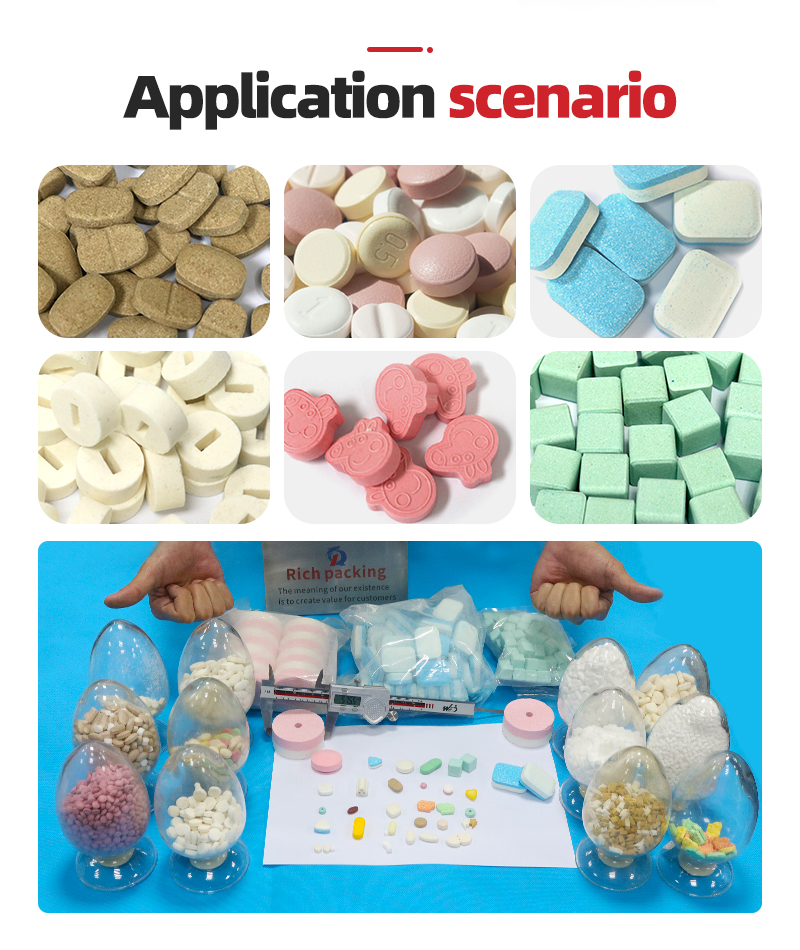

The high-speed dual pressure rotary zp25 55D tablet press is a tablet press that can compress tablets with a maximum diameter of 25mm. This machine has the dual pressure and high-efficiency tablet pressing function, which can effectively solve various urgent orders of customers. Therefore, it is also called the superstar in the tablet press by customers.

This rotary dual pressure ZP 25 55D equipment has strong dual pressure function strength, can make full and effective use of the high pressure function (the maximum pressure is 80KN), and can maintain the stable operation of the equipment while running at high speed. ZP 2555d can press different tablets of standard minimum size, and the output can exceed 230000 pieces in one hour.

According to the current market demand (users in the pharmaceutical industry, health care products industry, daily necessities industry, etc.), our company has specially developed and manufactured this high-speed double pressure rotary tablet press product. Firstly, the mechanical materials of zp2555d product of high-speed double pressure rotary tablet press are upgraded. The mechanical parts are accessible materials sus 316L (reaching zero penetration and zero pollution in the field of pharmacy and food). Secondly, large-size effervescent tablets, disinfection tablets, detergent tablets, dishwashing tablets and difficult to compress and corrosive materials can also be pressed and produced smoothly, which is also known as the star tablet press.