ZP 17D Automatic Rotary Tablet Making Pharmaceutical Powder Tablet Press Machine

| Model | ZP11D | ZP15D | ZP17D | ZP19D | ZP21D |

| Dies No. | 11 | 15 | 17 | 19 | 21 |

| Max. Pressure | 100kn | 80 kn | 60 kn | 60 kn | 60 |

| Max. Diameter | 40mm | 25 mm | 20 mm | 13 mm | 12 mm |

| Max.Thicknes | 10 mm | 6 mm | 6 mm | 6 mm | 6 mm |

| Max. Capacity(pcs/h) | 13200 | 27000 | 30600 | 34200 | 37800 |

| voltage | 220v/380v | ||||

| Size | 890*650*1680mm | ||||

| Weight | 1000kg | ||||

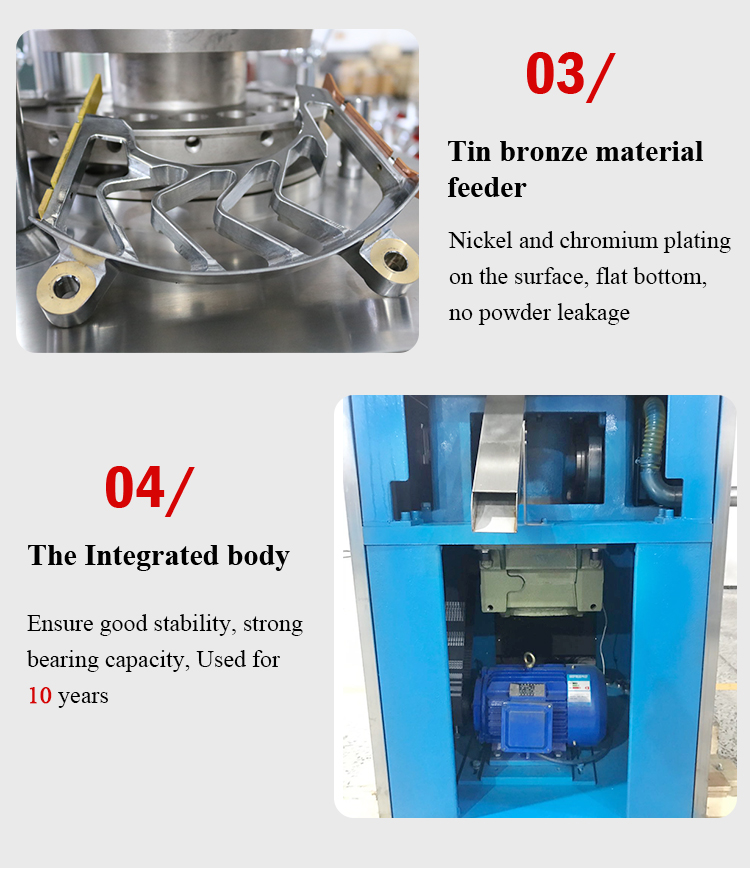

The fully automatic rotary tablet forming pharmaceutical tablet press 17D with modular structure and reasonable design is a new type of stainless steel machine developed by our factory. The tablet pressing multi punch tablet machine has stable overall structure, low noise, high pressure, easy operation and maintenance. This 17D medium-sized tablet pressing machine is suitable for chemical industry, pharmacy and food. The fully automatic powder tablet press can be used to press the tablets of food, pharmaceutical and health care products. The fully automatic particle rotary tablet press has stable tablet weight and sensitive adjustment. The particle tablet press equipment has high operation precision and the machine runs smoothly as a whole.

The powder automatic tablet press is equipped with an anti touch digital display adjustment handwheel : the specially designed precise digital display adjustment function, coupled with the handwheel design that can be locked at any time, makes it easier and more accurate for the staff to adjust in place and the tablet weight is more stable when operating and adjusting in actual production. After the adjustment of the machine is completed, the determined value can be locked with one button to prevent the operator from inadvertently touching the hand wheel, resulting in data deviation, which will affect the tablet pressing effect.

The multi impact rotary tablet press adopts the upper and lower guide rail curve and angle design, so it runs smoothly without trouble. It is made of nodular cast iron qt500 high-quality solid bar. It is firm, heat-resistant and wear-resistant, and its system performance is stable. The contact position of the stainless steel full-automatic rotary tablet press that meets GMP requirements is non-toxic, odorless and corrosion-resistant. It is suitable for the chemical industry, pharmaceutical industry, food industry and other industries.