ZP-29D Pharmaceutical Automatic Rotary Making Pill Press Compression Tablet Compress Machine

Dies No. | 29 set |

Max. Production Capacity | 75000 pcs/h |

Max. Pressure of pill tablet press machine 29D | 100KN |

Max. Dia. of Tablet | 25mm |

Max. Depth of Filling | 24mm |

Max. Thickness of Tablet | 12mm |

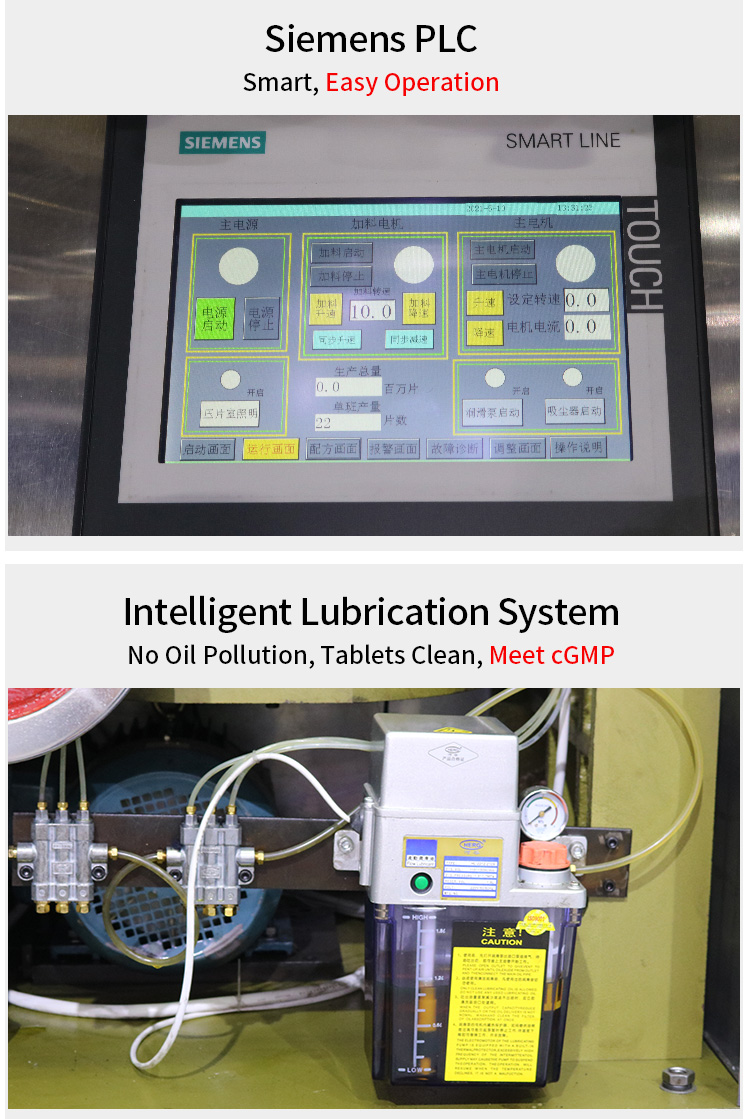

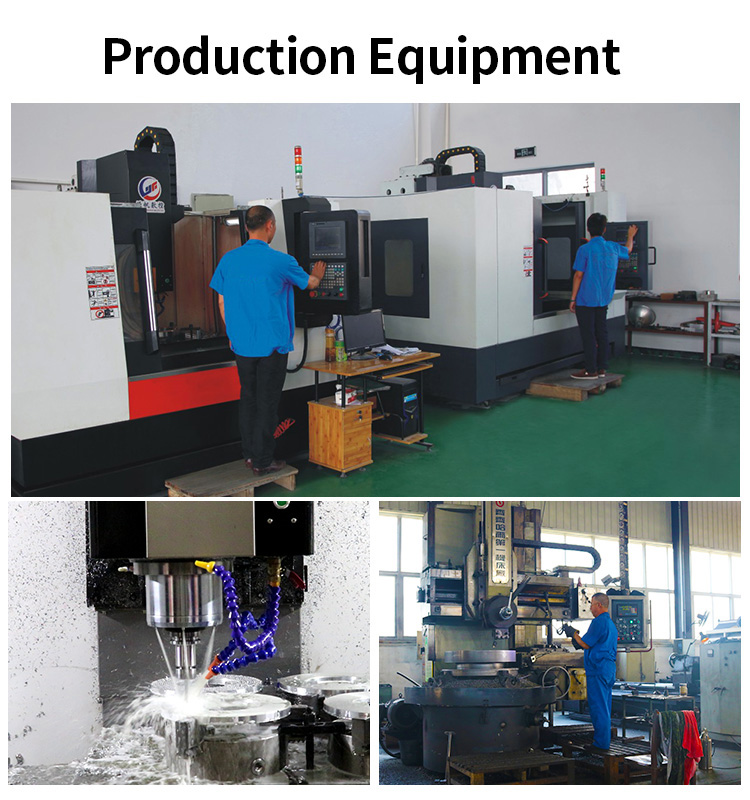

The automatic rotary tablet press is a new type of structure full-automatic rotary wafer machine developed by our factory. It has high pressure, easy operation and simple maintenance. The film maker is suitable for food, pharmaceutical and chemical industry. The full-automatic pharmaceutical tablet press uses cosine curve operation mode to move up and down the rails. Because the acceleration of the up stroke is 0, the machine is stable and does not jump, and the production task can be stable for 24 hours.

The automatic production machine of pharmaceutical factory can suppress disinfection tablets, effervescent tablets and cleaning tablets. The production machine of pharmaceutical factory has stable tablet weight, sensitive adjustment, high equipment precision and balanced operation. The powder tablet press has a 0.1mm hand wheel, which is convenient, fast and accurate to adjust, so as to ensure the stability of tablet weight.

The high-capacity automatic ingot beating machine has a special pressure overload protection device. Its working principle is to start the overload protection of the machine through the pressure of the spring, and there is an alarm light to prompt, so as to achieve intelligent automatic shutdown. The eccentric moment principle is effectively used to protect the mold and machine from damage. Compared with hydraulic overload protection, the eccentric torque overload protection of automatic rotary tablet press has the advantages of fast response and no oil pollution.