INTRODUCTION

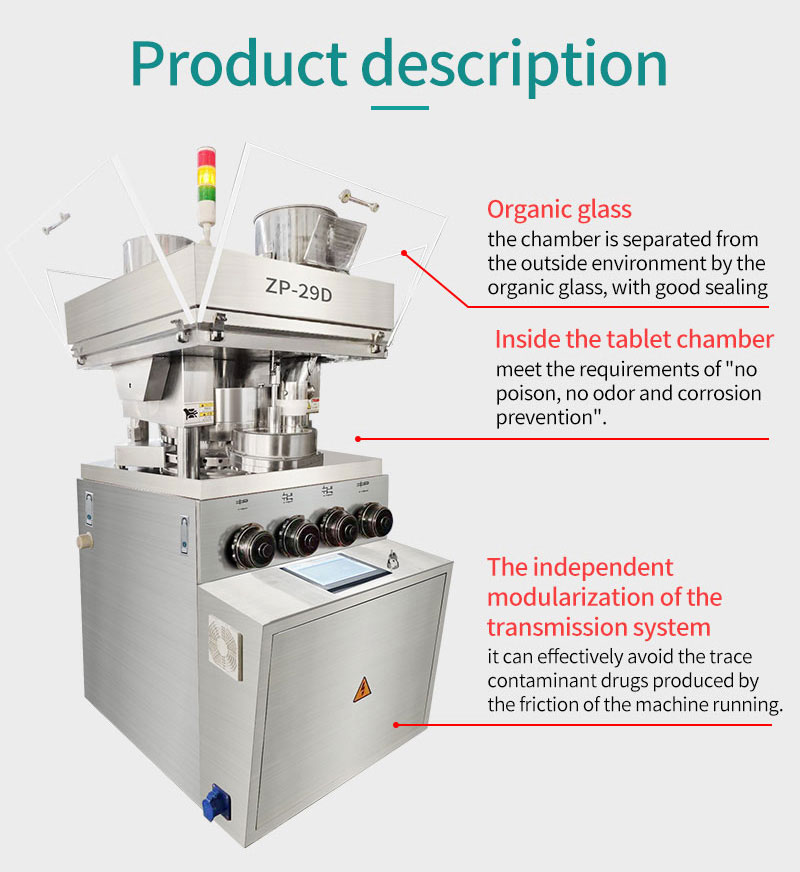

The RQ-ZPE-1000 Rotary Smart Tablet Press is a new generation of innovative products from Guangdong Ruiqi that can be used to compress powders or granules into round and shaped tablets of various shapes. This series of tablet presses has a high level of intelligence. The pressure, filling depth, speed and number of tablets are controlled by sensors and displayed on the plc screen. The design of HMI man-machine dialogue interface makes the main parameters of the tablet press appear, which is convenient for customers to obtain, verify, store and print various parameters.

The tablet press adopts a flat design, which is convenient for customers to operate and clean after use. It is in full compliance with GMP requirements and is the first choice for high-end tablet presses in the pharmaceutical, chemical, electronic, daily chemical, food and health products industries. This series of tablet presses can be equipped with forced feeders and sieve machines according to actual needs, and can be connected with the blister packaging machine, electronic counting machine and cartoning machine

FEATURES

1、This tablet press machine has high intelligence, design HMI man-machine dialogue interface, PLC control, pressure size, filling depth, speed and other functions are adjusted on the touch screen, accurate measurement, easy for data reading, verification and customer use.

2、This series of presses has high pressure, fast speed, stable operation and output of 18,000 pieces/hour.

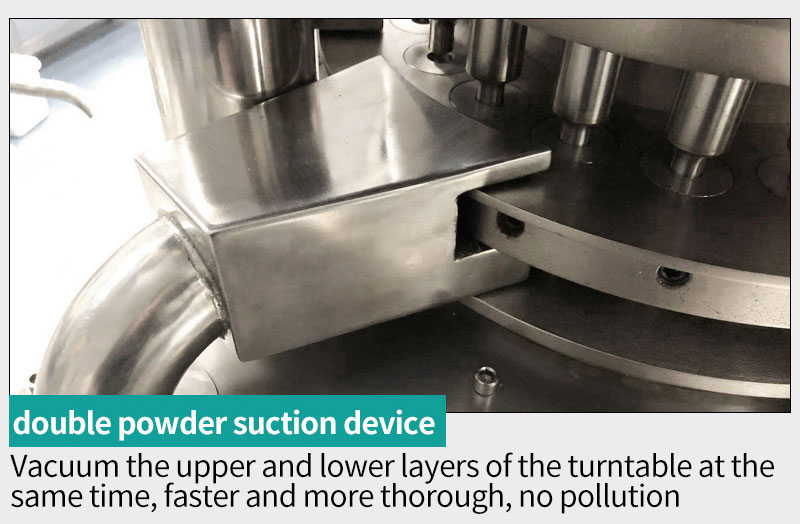

3、This type of tablet press machine is equipped with a forced feeding function, which enables smooth material cutting for materials with poor fluidity.

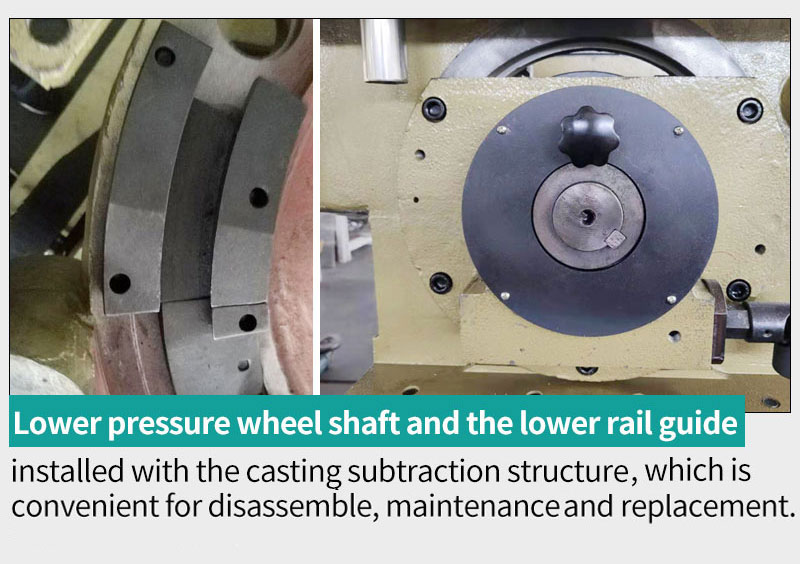

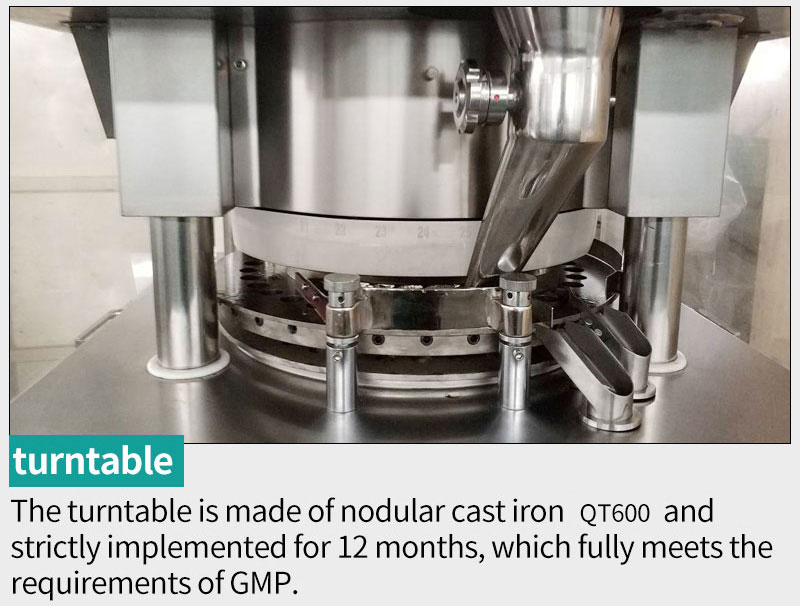

4、The tablet press machine is made of ductile iron and has a aging time of 12 months. It has stable chemical properties, hardness, corrosion resistance and durability.

5、The die of the tablet press machine adopts the European standard , and the upper punching has a groove of the oil-proof ring and is equipped with an oil-proof ring, which effectively prevents the problem of dripping oil and oil leakage.

6、Configure the motor overload protection system, a single pressure overload, automatic shutdown, protection equipment and personnel safety.

7、All use European standard grinding tools, durable and stable operation.